3D printing bionic bone trabecular structure lumbar vertebra fusion device, manufacturing method and application

A trabecular structure, 3D printing technology, applied in spinal implants and other directions, can solve problems such as surgical failure, and achieve the effect of short fusion time and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

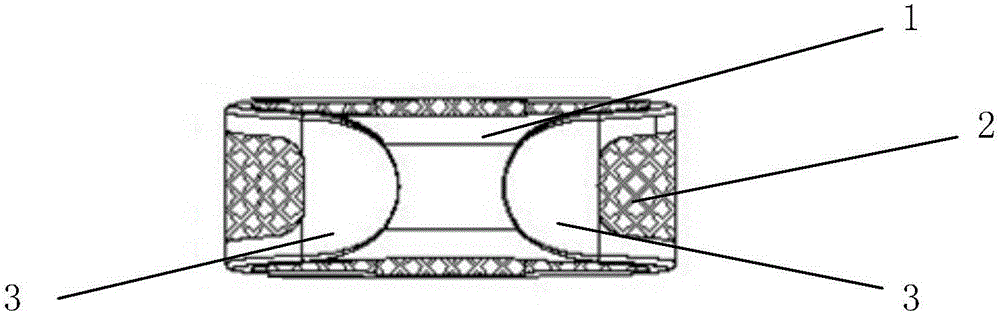

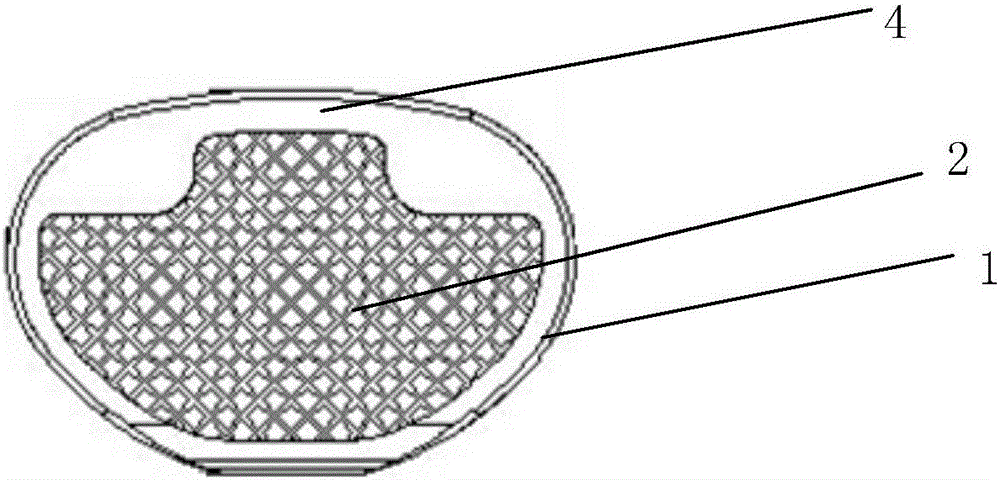

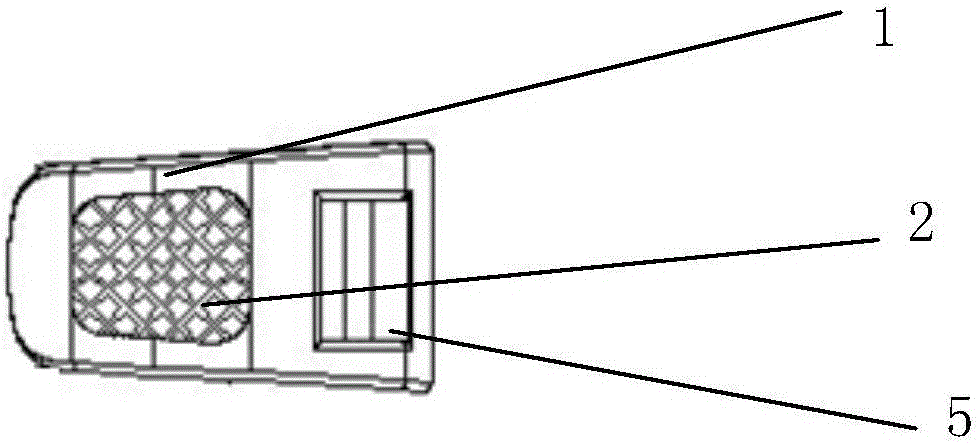

[0031] Such as Picture 1-1 , Figure 1-2 , Figure 1-3 , diagram 2-1 , Figure 2-2 , Figure 2-3 , Figure 2-4 , Figure 3-1 , Figure 3-2 , Figure 4 A 3D printing bionic trabecular structure lumbar fusion device for lumbar surgery shown includes a physical support, the physical support includes a horizontal plane physical support 1, a front end physical support 3, and a tail end physical support 4; the middle of the physical support is Porous structure 2.

[0032] The tail-end solid support 4 is provided with a gripper bayonet 5 .

[0033] The porous structure 2 is a microporous octahedral structure.

[0034] The surrounding part of the product is a solid support part, and its function is to increase the compressive strength of the fusion device. The design of the lumbar fusion device can be divided into implantation from the anterior, posterior and lateral routes. According to the different implantation sites, it is designed as a rectangular ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com