An inner cover cleaning machine with improved cleaning efficiency

A cleaning efficiency, cleaning machine technology, applied in cleaning methods and utensils, cleaning methods using liquids, cleaning methods using tools, etc., can solve problems such as difficult to effectively clean the inner cover, and achieve simple structure, strong practicability, and effective cleaning. cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Specific embodiments of the present invention will be described below with reference to the accompanying drawings.

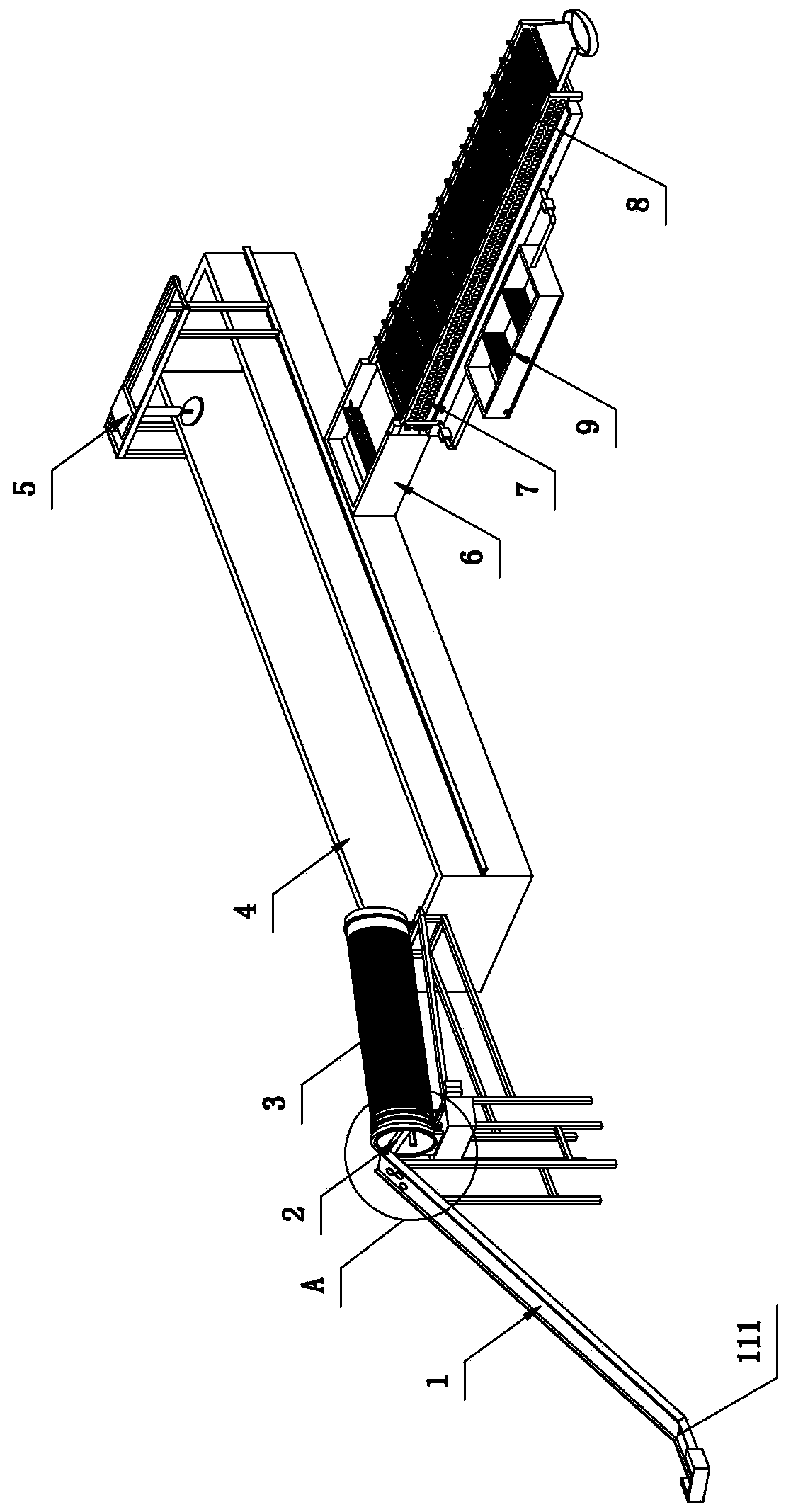

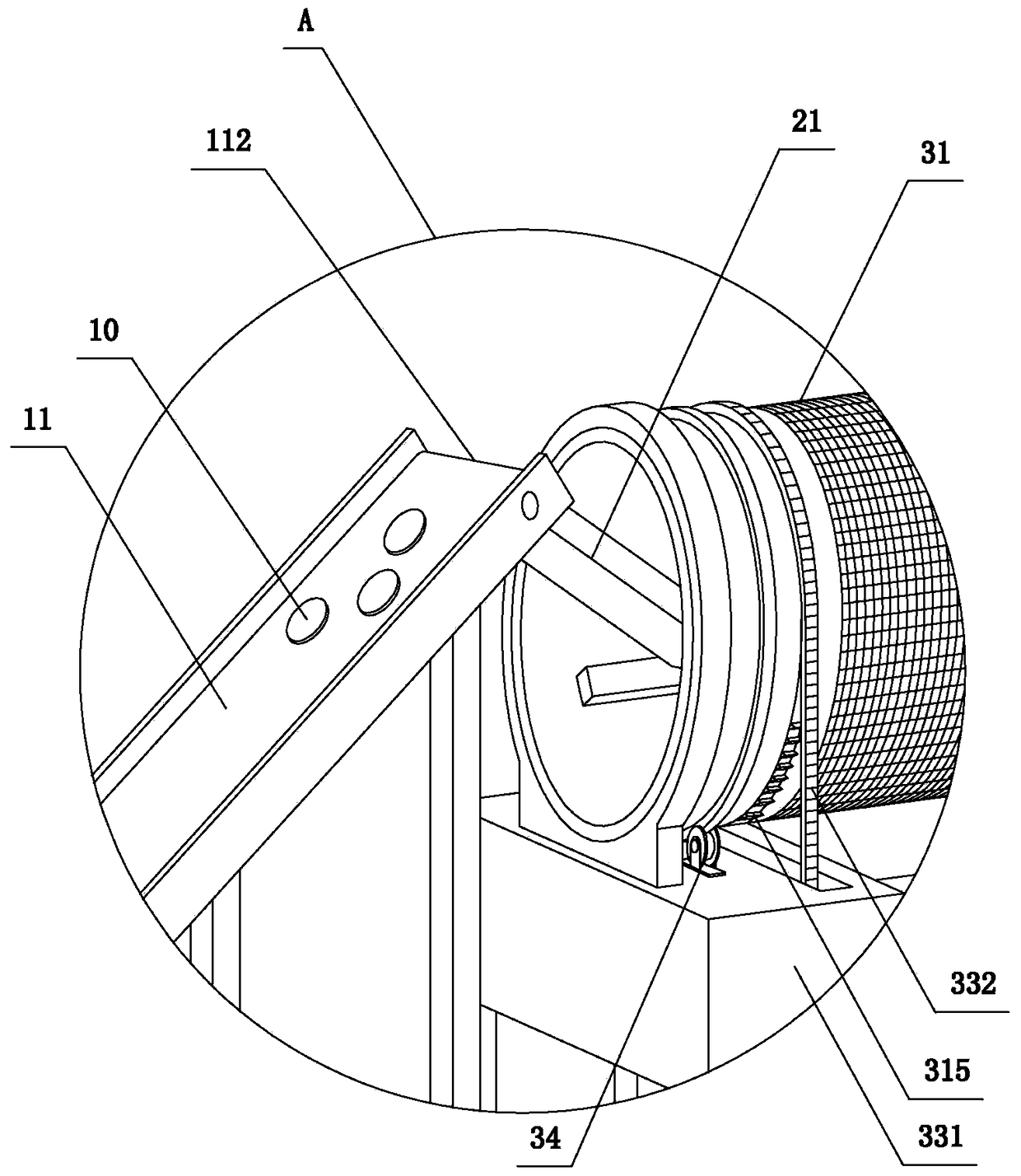

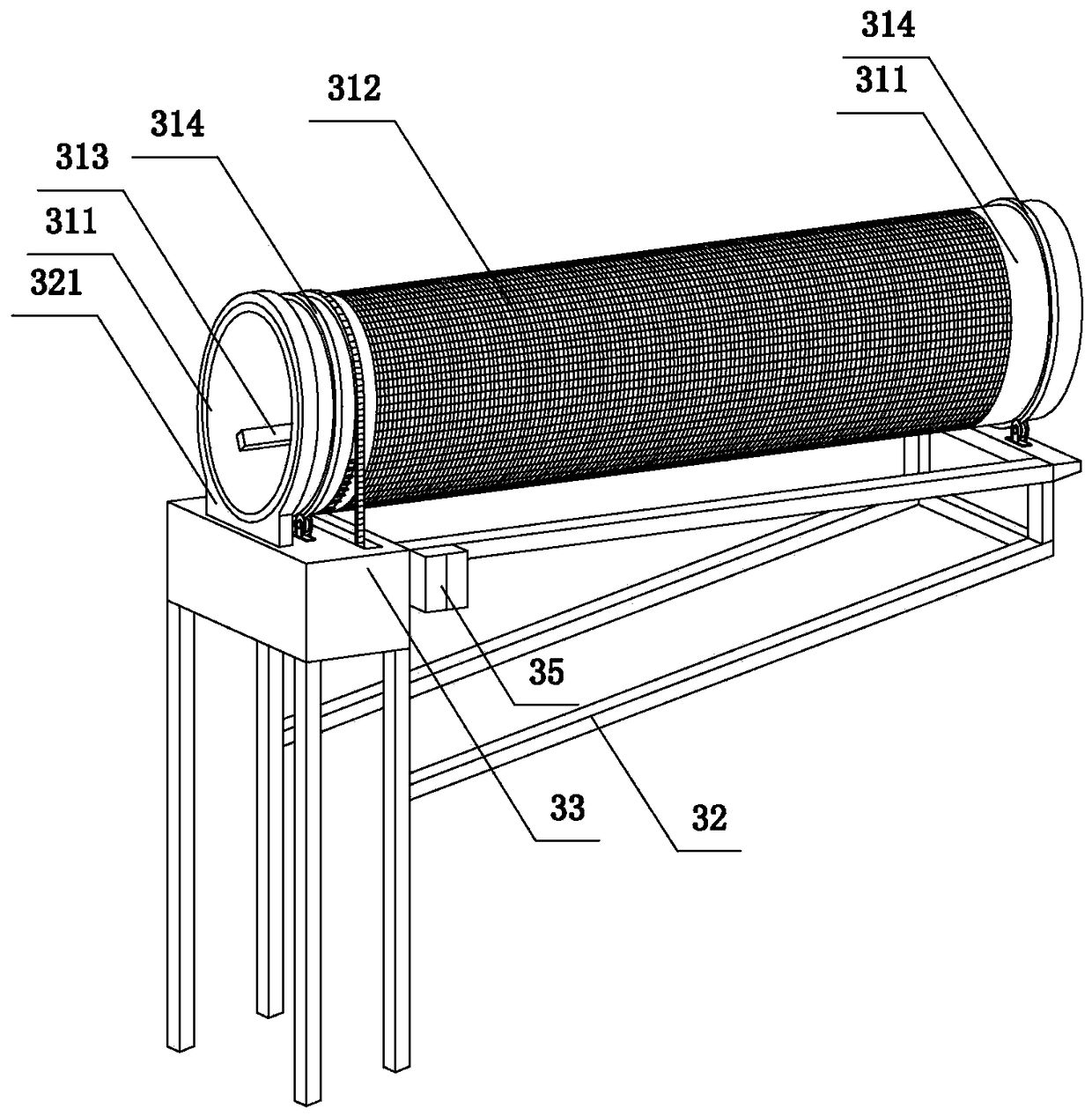

[0045] refer to figure 1 . An inner cover cleaning device, comprising a material transfer device 1, a transition transfer device 2, a drum cleaning device 3, a soaking device 4, an inner cover transfer device 5, a cover sorting device 6, an inner cover cleaning machine 7, a spray device 8 and water Recovery unit 9.

[0046] Among the above components, the output end of the material transfer device 1 is connected to the input end of the drum cleaning device 3 through the transition transfer device 2; the output end of the drum cleaning device 3 is located above the soaking device 4; the inner cover transfer device 5 is installed in the soaking On the side of the device 4, the inner cover can be transferred from the soaking device 4 to the feed end of the cover arrangement device 6; the discharge end of the cover arrangement device 6 is connected to the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com