Pressure regulation and control eliminating module for hydraulic pipe bender system

A technology of system pressure and pipe bending machine, applied in the direction of mechanical pressure/force control, control/regulation system, non-electric variable control, etc., can solve the problems affecting the operation effect and the numerical requirements of the system pressure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

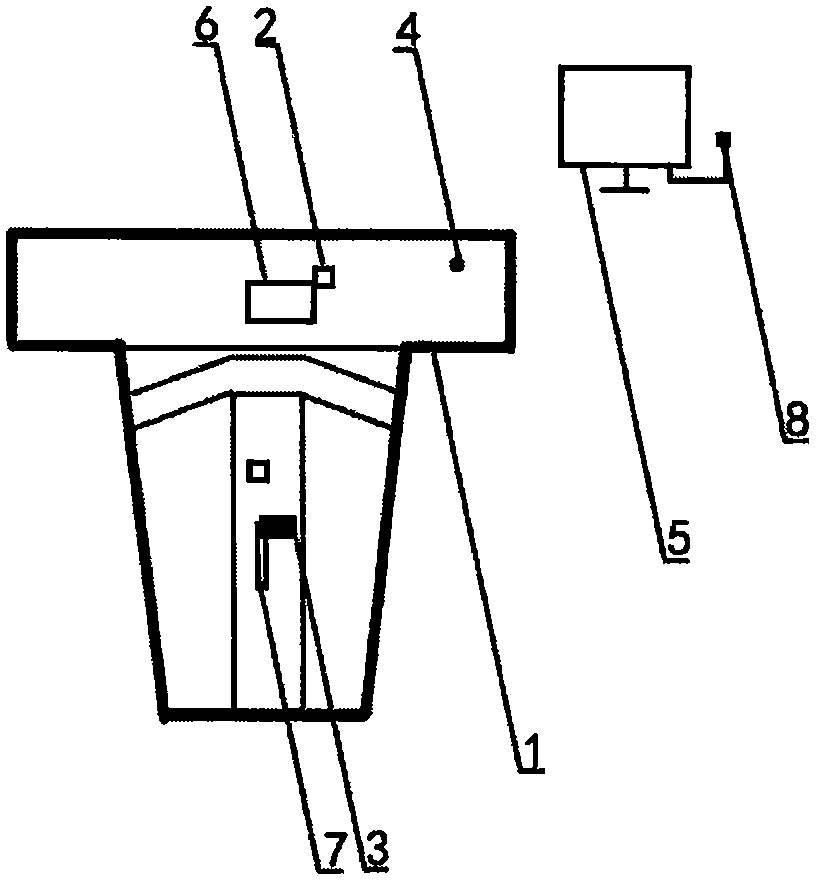

[0012] Embodiment: as shown in the accompanying drawing. The pressure regulation and elimination module of the hydraulic pipe bending machine system includes a body (1), on which a pressure sensing module (2), an elimination module (3), a remote communication module (4), and a management module (5) are arranged, During operation, pressure sensing modules (2) are respectively set on the body (1) to sense the pressure values of various places, and the sensed pressure values are transmitted to the management module (5) through the remote communication module (4) for processing, and the elimination module (3 ) to eliminate unsuitable pressure.

[0013] The pressure regulation and elimination module of the hydraulic pipe bending machine system is provided with a setting module (6) on the pressure sensing module (2) to set an appropriate value range of the pressure that each part of the fuselage bears.

[0014] The pressure regulation and elimination module of the hydraulic pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com