Automatic control and alarming system of molten steel liquid level in crystallizer of continuous casting machine

A liquid level automatic control and control system technology, which is applied to the configuration of manufacturing tools, casting equipment, indicating equipment/measuring equipment, etc., can solve the problem that the personal experience differences of steel workers are greatly affected, affecting product quality and production stability, Workers' labor intensity is high, and the effect of ensuring long-term stable operation, improving power supply reliability, and reliable practicability is achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

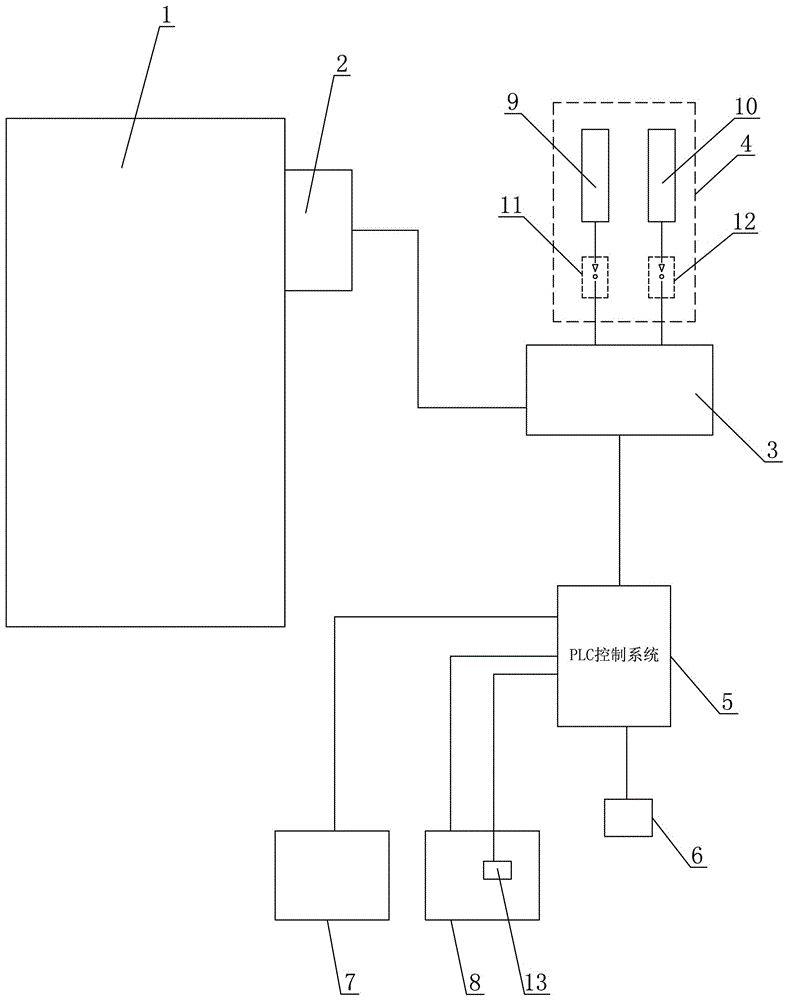

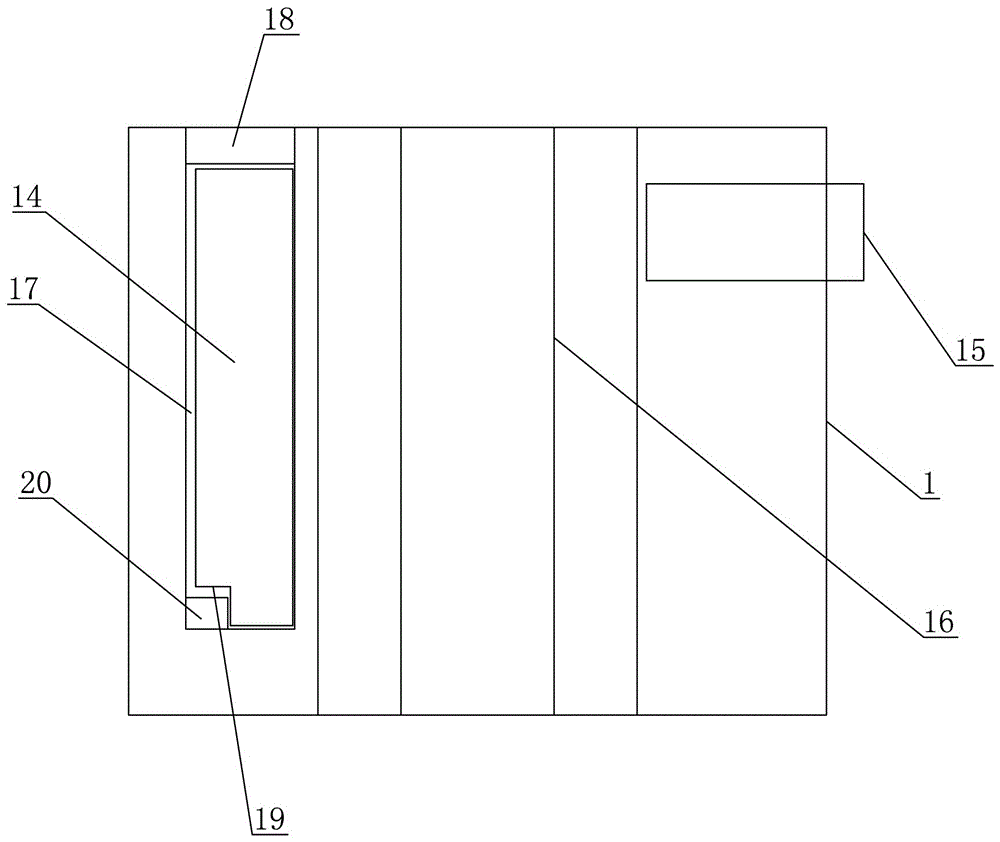

[0015] like figure 1 , figure 2 As shown, the automatic control and alarm system for the molten steel level in the mold of the continuous casting machine includes a liquid level detector 2 installed on the mold 1, the liquid level detector 2 is electrically connected to the liquid level signal processor 3, and the liquid level detector 2 is electrically connected to the liquid level signal processor 3. The surface signal processor 3 is powered by the power supply system 4, the liquid level signal processor 4 is electrically connected to the PLC control system 5, and the PLC control system 5 is electrically connected to the buzzer alarm 6, the tension straightening machine control system 7 and the picture display 8 at the same time; The liquid level detector 2 can monitor the liquid level of the molten steel in the crystallizer 1 in real time,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com