A welding manufacturing device for tie rod structural parts

A technology for making devices and structural parts, applied in auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve the problems of easy errors in welding production, low welding efficiency of T-shaped plates and steel pipes, etc. The effect of improved quality and efficiency, and improved perforation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

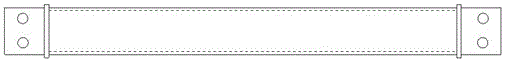

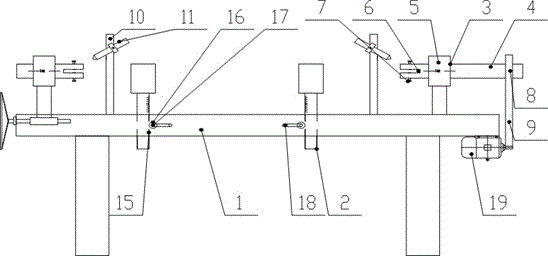

[0030] Such as Figure 2-4 As shown, a welding manufacturing device for a tie rod structural part of the present invention includes a tie rod welding table 1, a steel pipe bracket 2, a T-shaped plate clamping main rotating assembly 3 and a T-shaped plate clamping secondary rotating assembly 20. A steel pipe bracket 2 is set on the tie bar welding table 1, and a steel pipe can be placed there. By setting a T-shaped plate on the tie rod welding table 1 to clamp the main rotating assembly 3, the T-shaped plate can be clamped, and the main rotating assembly can be clamped through the T-shaped plate. The rotating assembly 3 can drive the T-shaped plate to be rotated and welded; the middle part of the tie bar welding table 1 is provided with two sets of steel pipe brackets 2, and the T-shaped plate is clamped with the main rotating assembly 3, which includes the main rotating shaft 4, the main rotating shaft support 5 and the motor 19. The main rotating shaft bracket 5 is arranged o...

Embodiment 2

[0034] Such as Figure 2-4As shown, the present invention is a welding manufacturing device for tie rod structural parts. On the basis of Embodiment 1, the tie rod welding table 1 corresponds to the inner end of the main rotating shaft 4 and the inner end of the secondary rotating shaft 21. Welding torch brackets 10 are respectively arranged at each place, and welding torches 11 are installed on the welding torch brackets 4 . It can eliminate the need for workers to weld with welding torches, and the quality and efficiency of welding are greatly improved; full-automatic welding can be realized, and the efficiency of tie rod welding can be effectively improved.

Embodiment 3

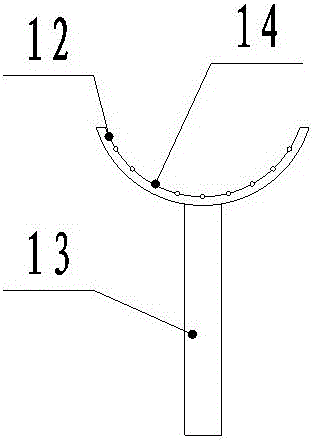

[0036] Such as Figure 2-4 As shown, the present invention is a welding manufacturing device for a tie rod structure. On the basis of Embodiment 1, the steel pipe bracket 2 includes an arc-shaped bracket 12 for placing steel pipes and a supporting column 13, and the arc-shaped bracket 12 is arranged on the support The upper end of the column 13 and the lower end of the support column 13 are arranged on the tie bar welding table 1 . Balls 14 are arranged on the inner arc surface of the arc-shaped bracket 12 .

[0037] The support column 13 is installed in the installation hole provided on the tie bar welding table 1, the support column 13 side is provided with a bar tooth 15, and the side of the installation hole is provided with a gear 16 that cooperates with the bar tooth 15, and the gear 16 rotates around the rotating shaft 17 , the said rotating shaft 17 is connected with a hand crank shaft 18. The steel pipe bracket 2 is provided with an adjustable height structure, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com