Automatic wire take-up reel rocking machine

A technology of a shaker and a wire take-up mechanism is applied in the directions of rotating and wrapping articles, transporting filamentous materials, and processing thin materials, which can solve problems such as excessive production space, affecting production efficiency, wasting production resources, etc. , the effect of improving production efficiency and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

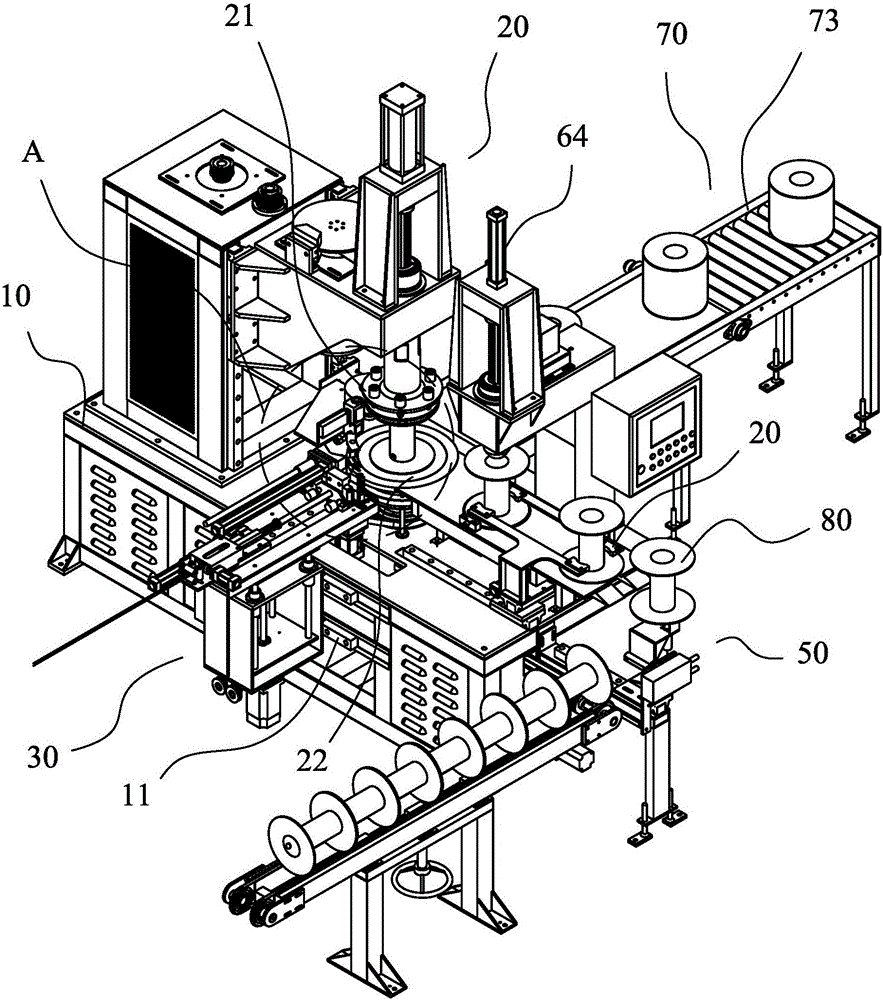

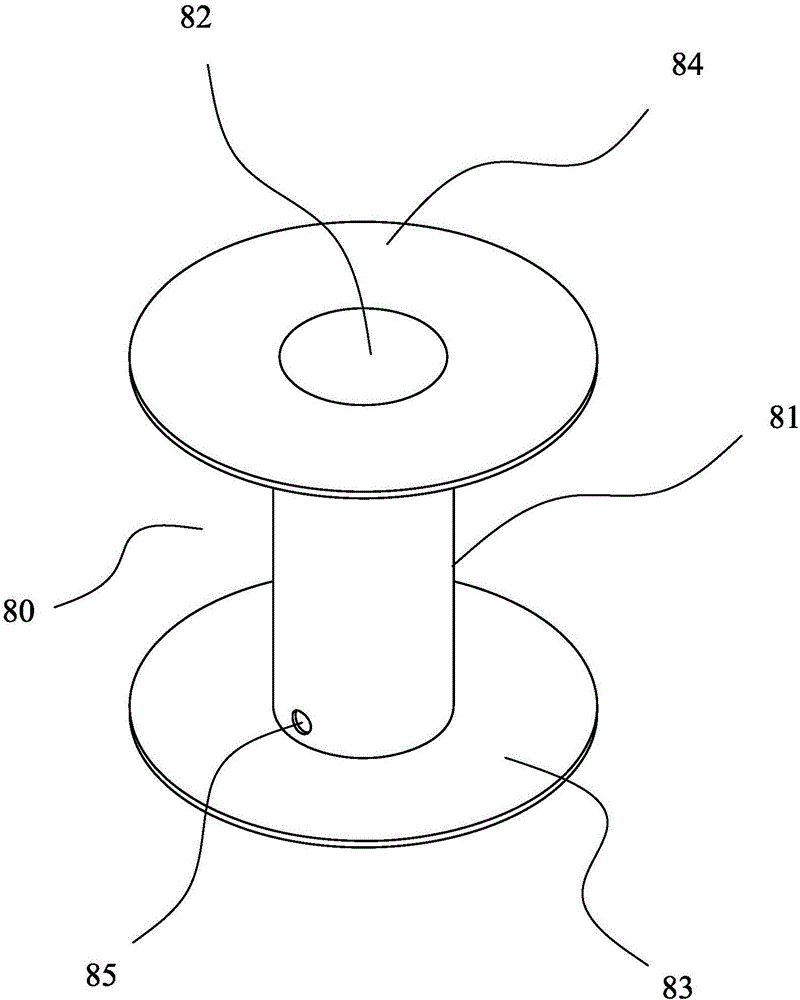

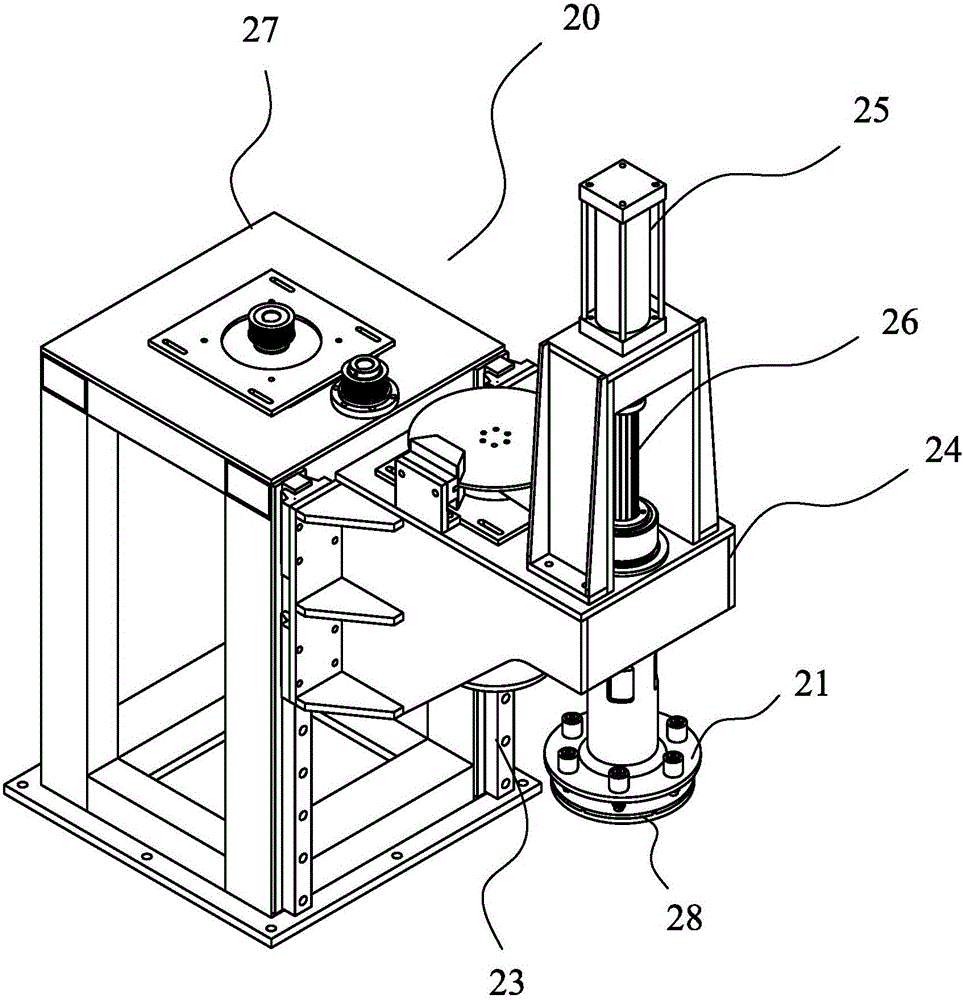

[0026] First, please refer to figure 1 As shown, an automatic wire take-up shaking machine includes a frame 10, and the frame 10 is provided with a wire take-up mechanism 20 that drives the winding reel 80 to rotate, and the wire take-up mechanism 20 includes a The turntable 21 and the compression head 22 arranged above the turntable 21, when working, the winding disk 80 is clamped between the turntable 21 and the compression head 22, and is driven by the driving element to wind the wire on the winding disk 80 top; also includes an automatic upper plate mechanism 50 that automatically conveys the winding reel 80 to the turntable 21, an automatic wire feeding mechanism 30 that automatically conveys the wire rod to the winding reel 80, and a lower plate mechanism 70, the lower plate mechanism 70 includes a lower winding material belt 73 and a pushing device for winding the winding reel 80 down to the material belt 73, and the wire take-up mechanism 20 also includes a wire take-u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com