A method for remediation of surface water contaminated sediment and control of nutrient release

A bottom mud and surface technology, applied in water/sludge/sewage treatment, sludge treatment, sludge treatment, etc., can solve the problem that the fixing capacity of zirconium-modified zeolite is not very high, and achieve long effective duration and good repair , The effect of reducing the gas supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

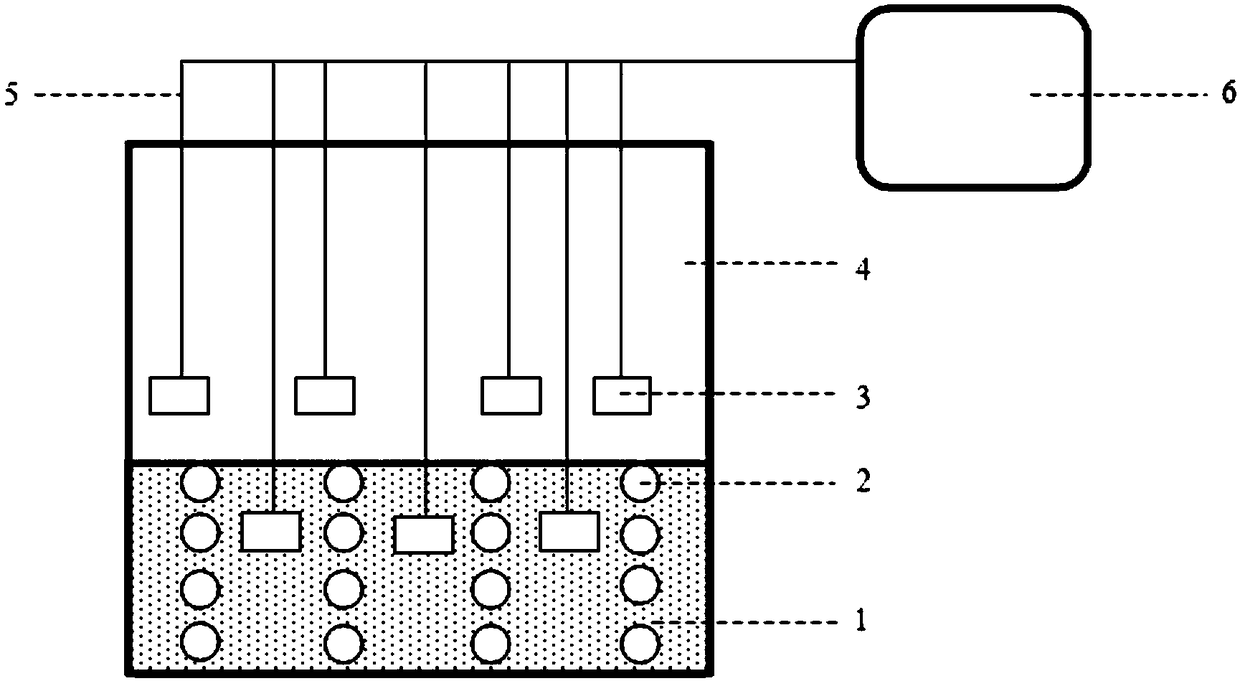

Method used

Image

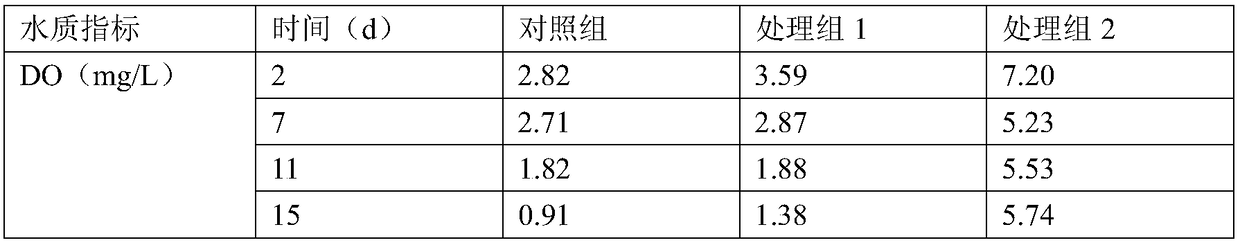

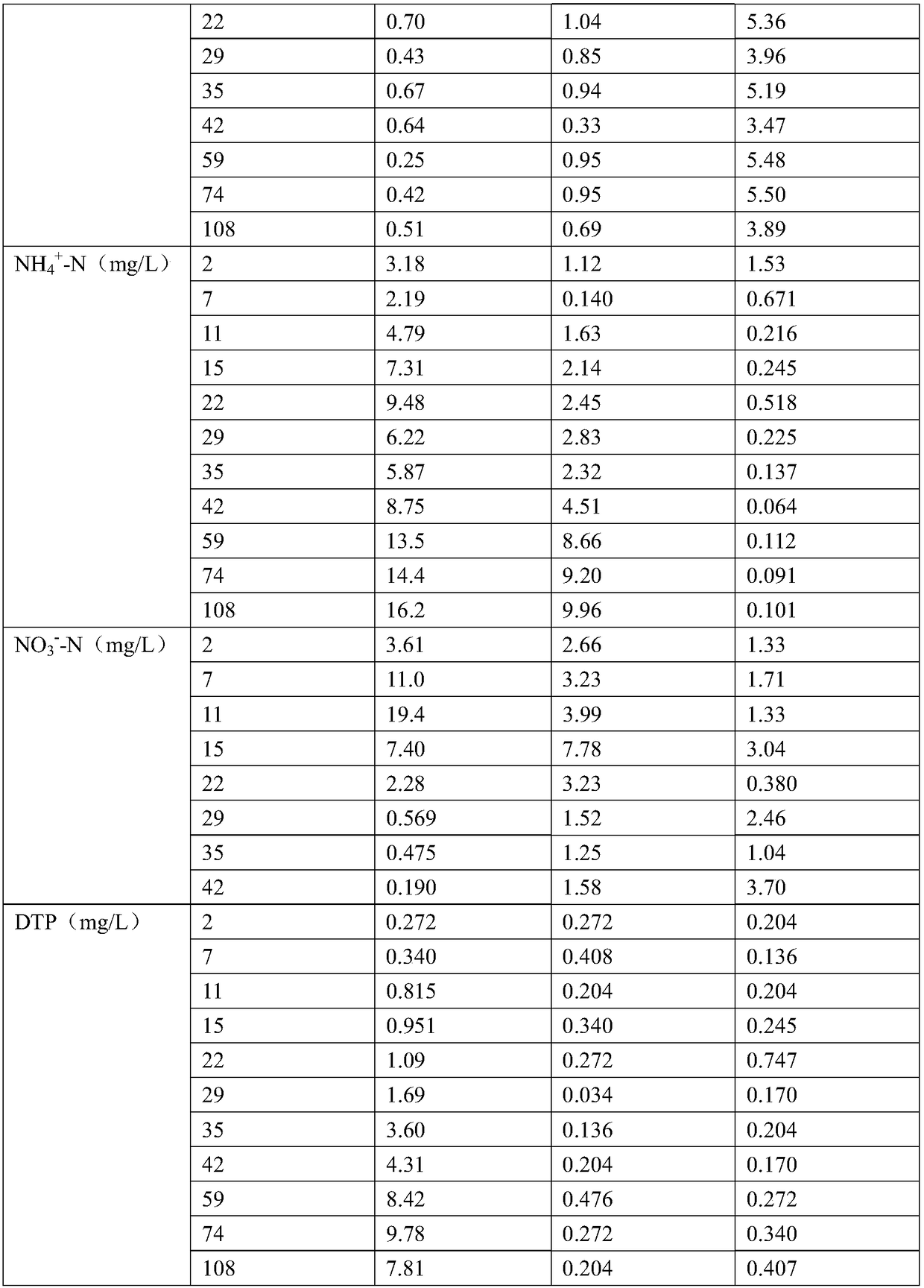

Examples

Embodiment 1

[0036] Example 1 Preparation of zirconium calcium modified zeolite (1)

[0037] Herein, the natural zeolite refers to an aluminosilicate crystal mineral with a skeleton structure existing in nature.

[0038] (a) Preparation of calcium-modified zeolite: use calcium chloride to prepare Ca with a concentration of 1mol / L 2+ Solution, weigh a certain quality of natural zeolite and place it in a container, then pipette Ca according to the liquid-solid ratio of 10mL / g 2+ The solution was fully mixed with the natural zeolite; the container was placed in a shaker and reacted for 24 hours under the reaction conditions of 150rpm and 25°C. After the reaction, the solid-liquid separation was carried out to obtain a solid material, and then the solid material was washed repeatedly until the AgNO 3 The solution does not detect Cl in the cleaning solution - , and dry to obtain calcium-modified zeolite;

[0039] (b) the calcium-modified zeolite and zirconium oxychloride octahydrate prepared...

Embodiment 2

[0040] Example 2 Preparation of Zirconium Calcium Modified Zeolite (2)

[0041] (a) Preparation of calcium-modified zeolite: adopting calcium chloride to prepare Ca with a concentration of 0.2mol / L 2+ Solution, weigh a certain quality of natural zeolite and place it in a container, then pipette Ca according to the liquid-solid ratio of 1mL / g 2+The solution was fully mixed with the natural zeolite; the container was placed in a shaker and reacted for 96 hours under the reaction conditions of 150rpm and 25°C. After the reaction, the solid-liquid separation was carried out to obtain a solid material, and then the solid material was washed repeatedly until the AgNO 3 The solution does not detect Cl in the cleaning solution - , and dry to obtain calcium-modified zeolite;

[0042] (b) the calcium-modified zeolite and zirconium oxychloride octahydrate prepared by step (a) are added together in the container, so that the mass ratio of calcium-modified zeolite and zirconium oxychlori...

Embodiment 3

[0043] Example 3 Preparation of Zirconium Calcium Modified Zeolite (3)

[0044] (a) Preparation of calcium-modified zeolite: use calcium chloride to prepare Ca with a concentration of 2.0mol / L 2+ Solution, weigh a certain quality of natural zeolite and place it in a container, then pipette Ca according to the liquid-solid ratio of 1000mL / g 2+ The solution was fully mixed with the natural zeolite; the container was placed in a shaker and reacted for 0.5h under the reaction conditions of 150rpm and 25°C. After the reaction, the solid-liquid separation was carried out to obtain a solid material, and then the solid material was washed repeatedly until the AgNO 3 The solution does not detect Cl in the cleaning solution - , and dry to obtain calcium-modified zeolite;

[0045] (b) the calcium-modified zeolite and zirconium oxychloride octahydrate prepared by step (a) are added together in the container, so that the mass ratio of calcium-modified zeolite and zirconium oxychloride oc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com