Warp strand unbinding device

A warp and untwisting technology, which is applied in the direction of twisting, auxiliary equipment for weaving, textiles, etc., can solve the problems of high working intensity and low efficiency, and achieve the effects of convenient installation and debugging, improving work efficiency and saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

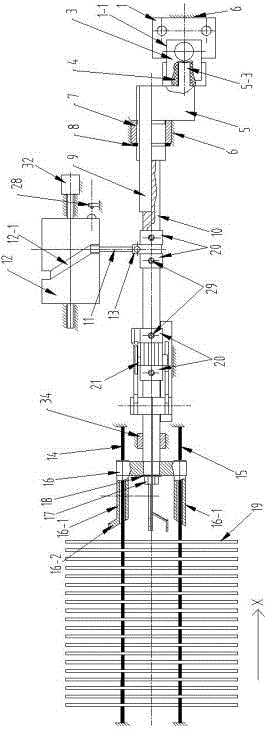

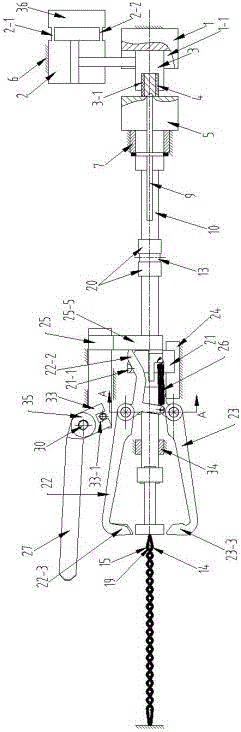

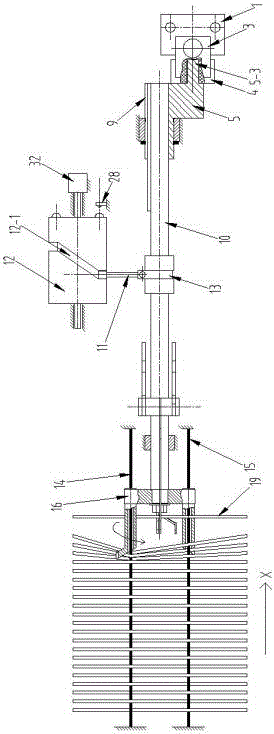

[0044] Embodiment 1: see attached figure 1 ~ attached Figure 14 , a warp yarn untwisting device, comprising a swing driving mechanism, a moving driving mechanism, an executing mechanism, a warp yarn isolating mechanism, and a warp yarn isolating and debugging mechanism.

[0045] The swing drive mechanism includes a cylinder 2 fixed to the frame 6 of the threading machine, a bracket 1 fixed to the frame 6 of the threading machine, a slider 3, and an eccentric shaft 5 movably connected to the frame 6 of the threading machine through a rear sliding bearing 7 , the left side of the rear sliding bearing 7 is provided with a retaining ring 8 for its axial limit, a bracket chute 1-1 is provided on the bracket 1, the cylinder 2 is opposite to the notch of the bracket chute 1-1, and the slider 3 Movably fit in the bracket chute 1-1, a slider groove 3-1 perpendicular to the bracket chute 1-1 is provided on the side of one end of the slider 3, and a spacer is movably fitted in the slid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com