Plant oil filter paper and preparation method for same

A vegetable oil and filter paper technology, which is applied in the field of filter paper, can solve the problems that vegetable oil filter paper is difficult to reach the target, and achieve good dry and wet strength, strong dust holding capacity, and uniform paper

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

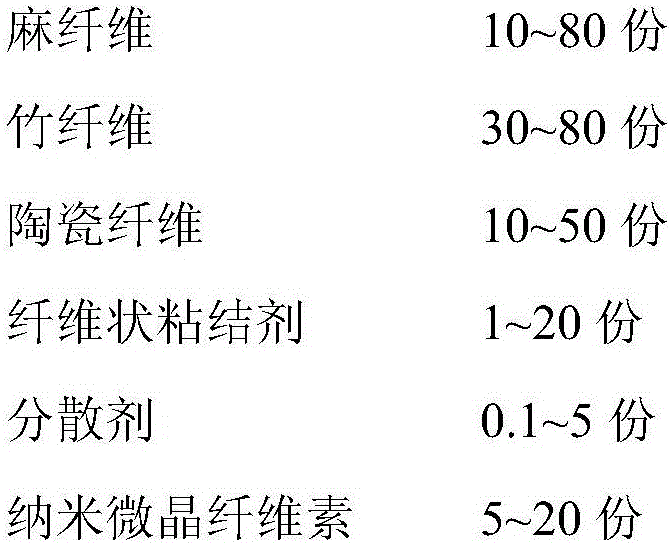

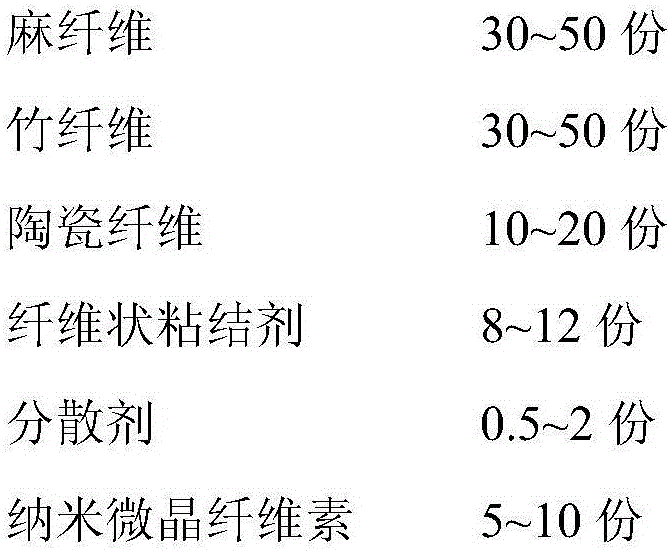

[0032] A vegetable oil filter paper, comprising hemp fiber, bamboo fiber, ceramic fiber, fibrous binder, dispersant and nano-microcrystalline cellulose, wherein the bamboo fiber is a nano-bamboo fiber with a fiber particle size of 80 to 100 nm; The ceramic fiber is nano-ceramic fiber, and the fiber particle size is controlled at 80-100nm; the fibrous binder is water-soluble PVA fiber; the dispersant is anionic polyacrylamide.

[0033] The preparation method of this vegetable oil filter paper comprises the steps:

[0034] a Dissolve 10kg of hemp fiber, 30kg of bamboo fiber and 1kg of fibrous binder into a single fiber with a beater, then add 10kg of ceramic fiber, 5kg of nanocrystalline cellulose, 0.1kg of dispersant and a certain amount of water to prepare A slurry with a concentration of 2.5%;

[0035] B forming the slurry obtained in step a on an inclined wire paper machine or a side flow cylinder paper machine;

[0036] c. After drying, coiling and cutting the formed filt...

Embodiment 2

[0038] A vegetable oil filter paper, containing hemp fiber, bamboo fiber, ceramic fiber, fibrous binder, dispersant and nano-microcrystalline cellulose; the bamboo fiber is a nano-bamboo fiber, and the fiber particle size is 80-100nm; The ceramic fiber is nano-ceramic fiber, and the fiber particle size is controlled at 80-100nm; the fibrous binder is water-soluble PVA fiber; the dispersant is anionic polyacrylamide.

[0039] The preparation method of this vegetable oil filter paper comprises the steps:

[0040] a 80kg of hemp fiber, 80kg of bamboo fiber and 50kg of fibrous binder are disintegrated into single fibers with a beater, and then 50kg of ceramic fiber, 20kg of nanocrystalline cellulose, 5kg of dispersant and a certain amount of water are added to form a concentration 4.5% slurry;

[0041] B forming the slurry obtained in step a on an inclined wire paper machine or a side flow cylinder paper machine;

[0042] c. After drying, coiling and cutting the formed filter pa...

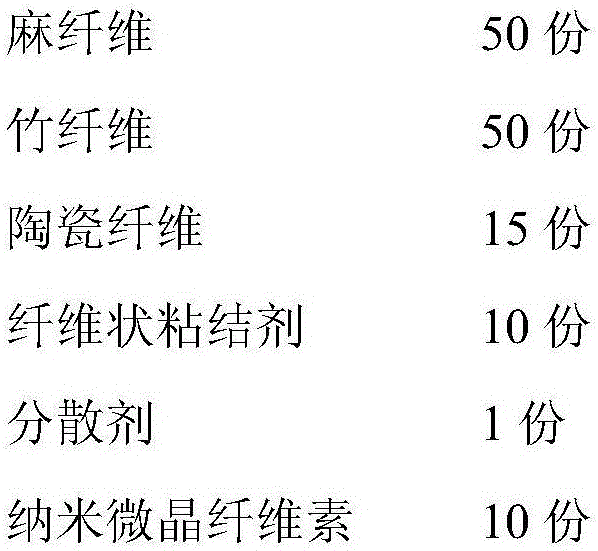

Embodiment 3

[0044] A vegetable oil filter paper, containing hemp fiber 5, bamboo fiber, ceramic fiber, fibrous binder, dispersant and nano-microcrystalline cellulose; the bamboo fiber is nano-bamboo fiber, and the fiber particle size is 80-100nm; The ceramic fiber mentioned above is nano-ceramic fiber, and the particle size of the fiber is controlled at 80-100nm; the fibrous binder is water-soluble PVA fiber; the dispersant is anionic polyacrylamide.

[0045] The preparation method of this vegetable oil filter paper comprises the steps:

[0046] a 50kg of hemp fiber, 60kg of bamboo fiber and 20kg of fibrous binder are disintegrated into a single fiber with a beater, and then 12kg of ceramic fiber, 10kg of nanocrystalline cellulose, 2kg of dispersant and a certain amount of water are added to form a concentration 3.5% slurry;

[0047] B forming the slurry obtained in step a on an inclined wire paper machine or a side flow cylinder paper machine;

[0048] c. After drying, coiling and cutt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap