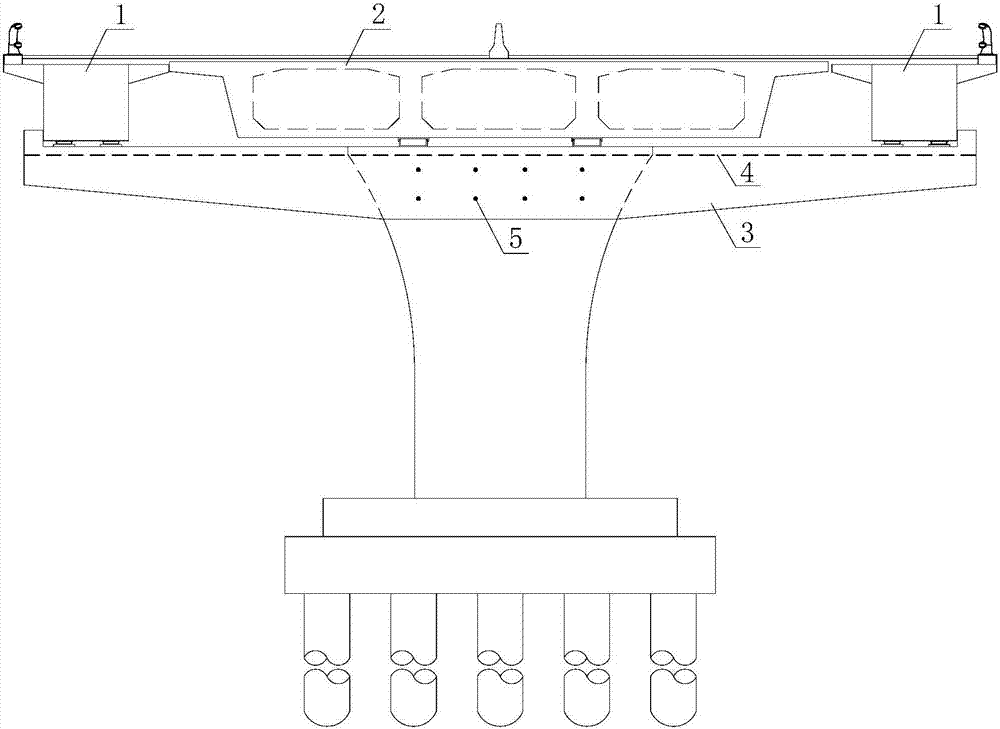

A bridge widening structure with a steel cap beam added to the top of the pier

A technology of steel cap girders and bridges, which is applied in the direction of erection/assembly of bridges, bridges, bridge maintenance, etc. It can solve the problems of interrupting traffic on the bridge, limited design load of widening, and impact of bridge piers on ground traffic, etc., to achieve ground traffic impact Small size, short construction period, and little impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

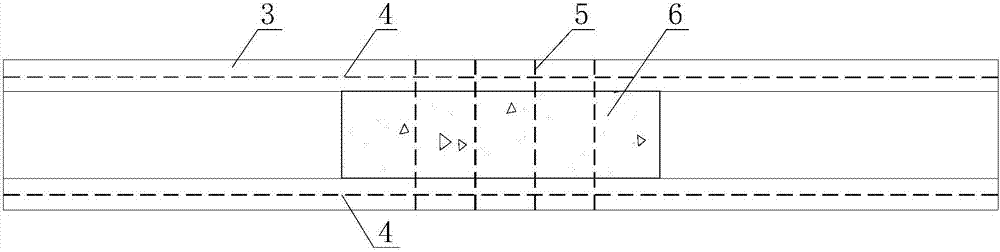

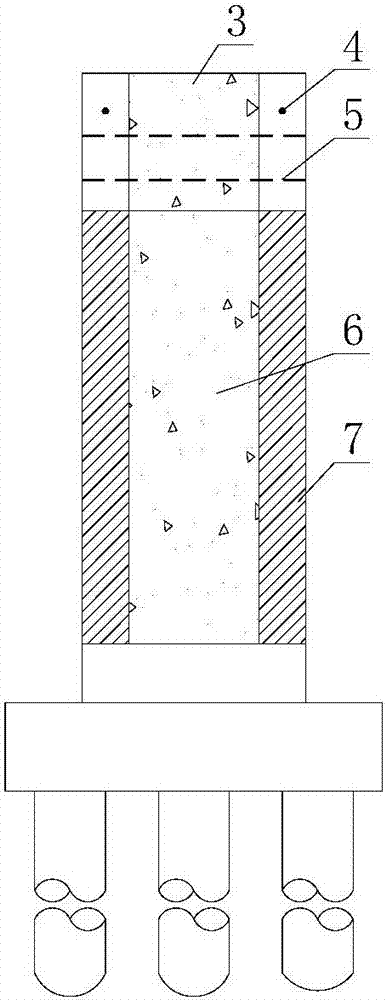

[0014] The specific embodiments of the present invention will be described in detail below in conjunction with the technical solutions and accompanying drawings.

[0015] The original bridge width is 18.5 meters, the main girder is a concrete box girder section, and the bridge width after widening is 26m. The specific construction process is as follows:

[0016] (1) Steel components such as steel cover beams and steel box girders on both sides are prefabricated in the factory.

[0017] (2) Chisel the original pier, plant reinforcement, pour concrete after pouring, thicken the longitudinal bridge of the pier by 0.5 meters, install the pre-buried section of the steel cover beam on the top of the thickened concrete layer, and tension and fix the pre-buried section of the steel cover beam. Stress anchor bars fix the steel cover beams and splice the remaining steel cover beams.

[0018] (3) Control the traffic on the bridge, remove the original bridge anti-collision guardrail and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com