A horizontal well staged fracturing wellhead automatic ball thrower

A technology of staged fracturing and ball throwing device, which is applied in wellbore/well components, production fluid, earth-moving drilling, etc., can solve the problems of limited number of fracturing balls, hidden dangers, time-consuming operation, etc., and achieve economical mining. , The effect of reducing production costs and reducing work intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

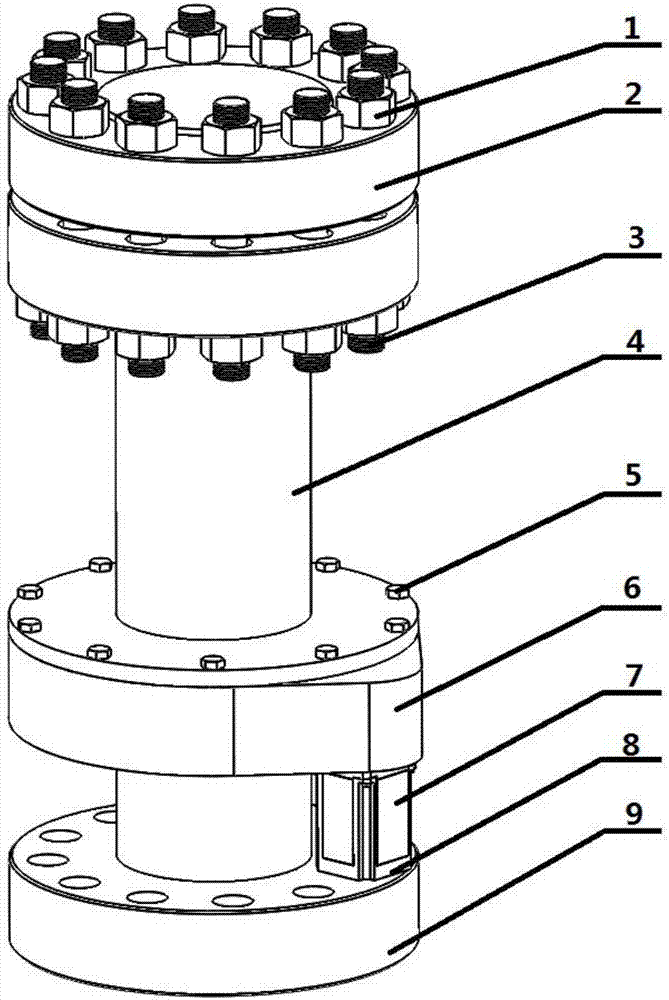

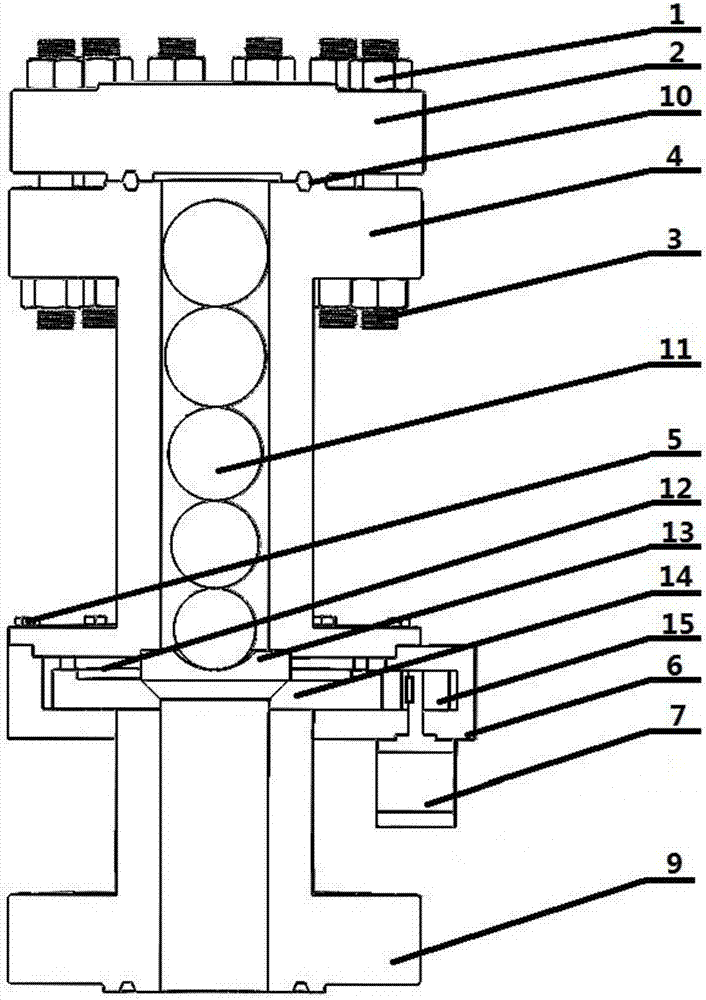

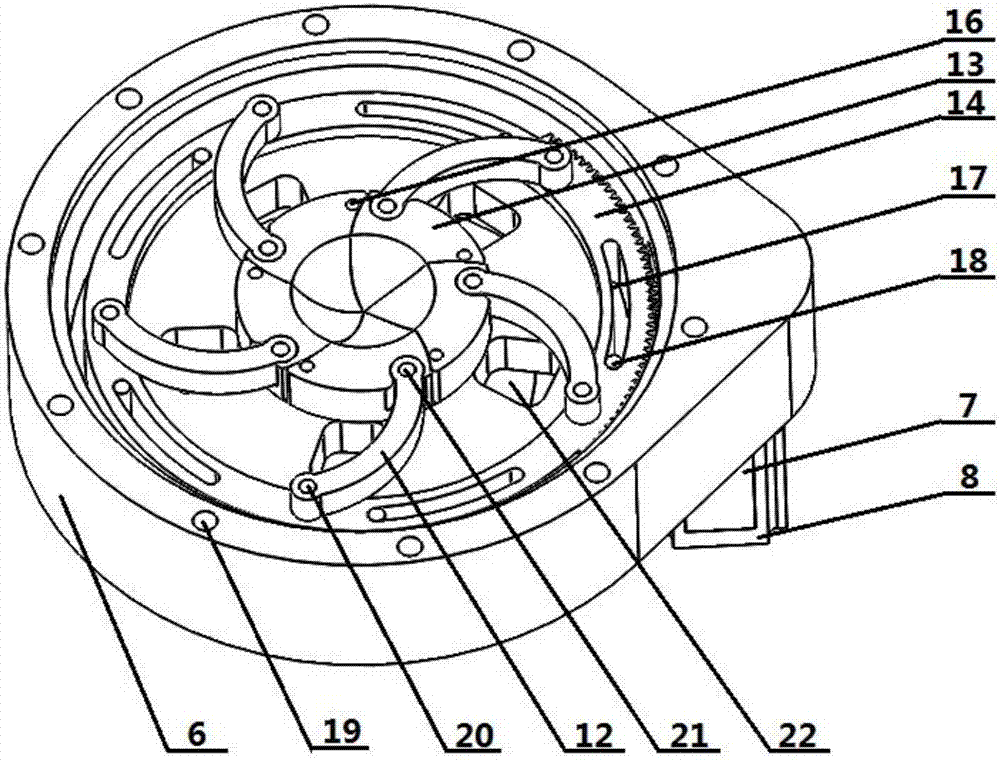

[0019] Such as figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, the horizontal well staged fracturing wellhead automatic ball thrower in the embodiment of the present invention includes a hex nut 1, a flange cover 2, a stud bolt 3, an upper joint 4, a fastening screw 5, a base 6, a ball throwing mechanism, The lower joint 9, the sealing ring 10, the fracturing ball 11 and the fastening screw hole 19, wherein the flange structure at the upper end of the upper joint 4 is used to load the fracturing ball 11, and the fracturing ball 11 is sealed with the flange cover 2 after the fracturing ball 11 is loaded , The upper flange structure of the upper joint 4 and the flange cover 2 are connected and fixed by the stud bolt 3 and the hex nut 1 . The sealing ring 10 at the connection between the flange structure at the upper end of the upper joint 4 and the flange cover 2 acts as a seal to prevent the high-pressure fracturing fluid inside the upper joint 4 from ov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com