A mechanism capable of continuously changing valve lift

A valve lift and continuous technology, applied in mechanical equipment, engine components, machines/engines, etc., can solve problems such as poor fuel economy and emission improvement, complicated control methods, and stiff driving experience, etc., to achieve improved combustion Efficiency and fuel economy, simple and fast control, smooth adjustment process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

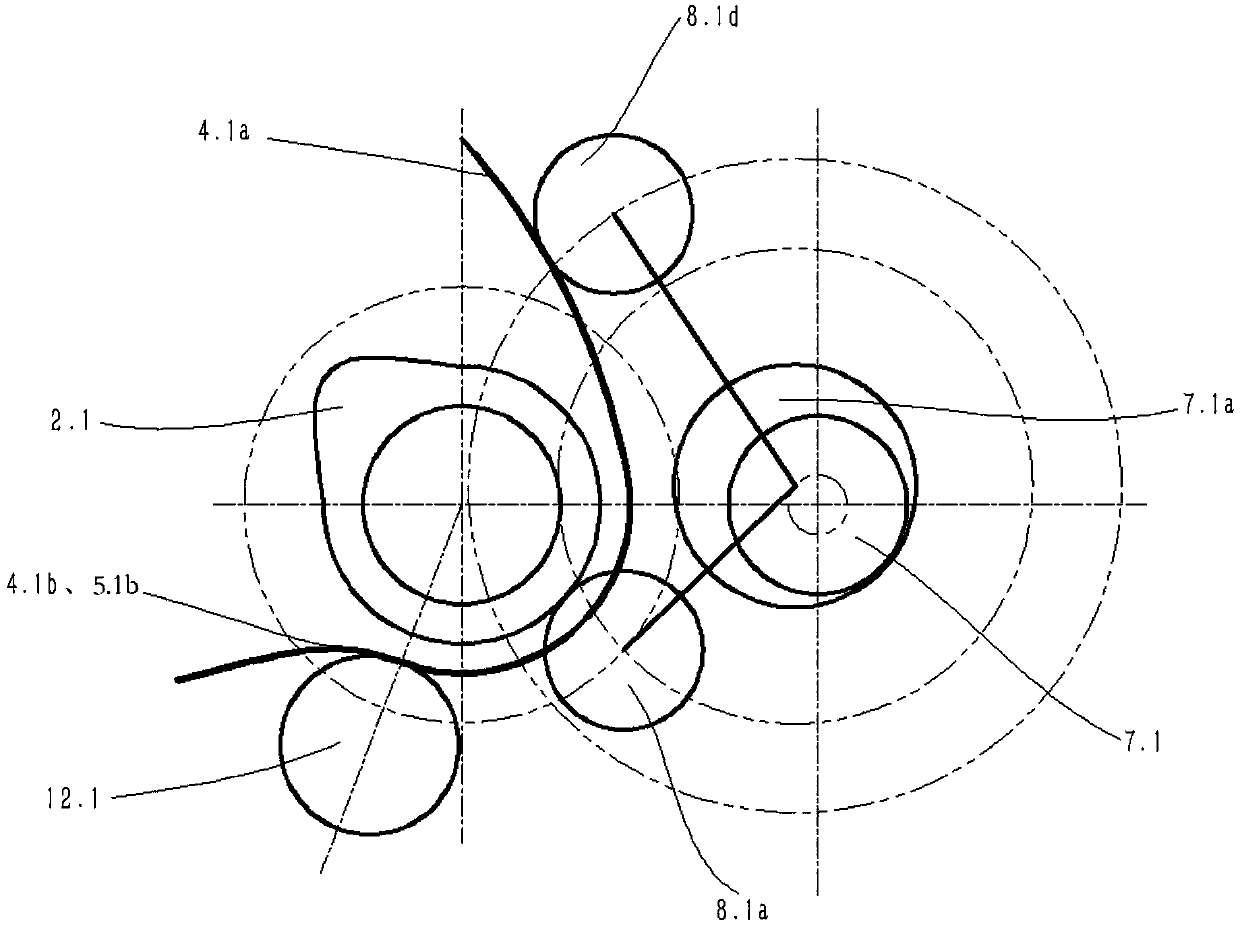

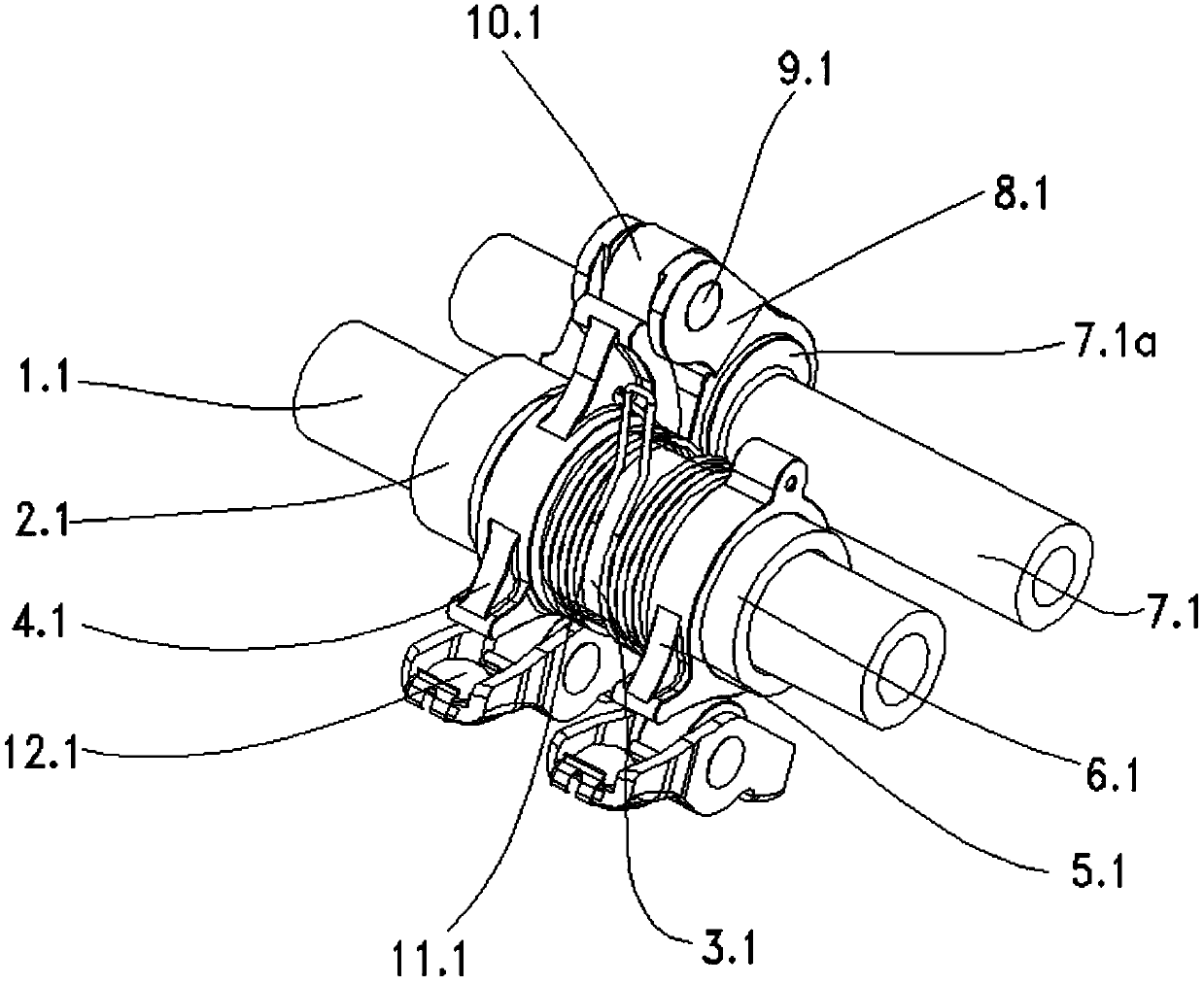

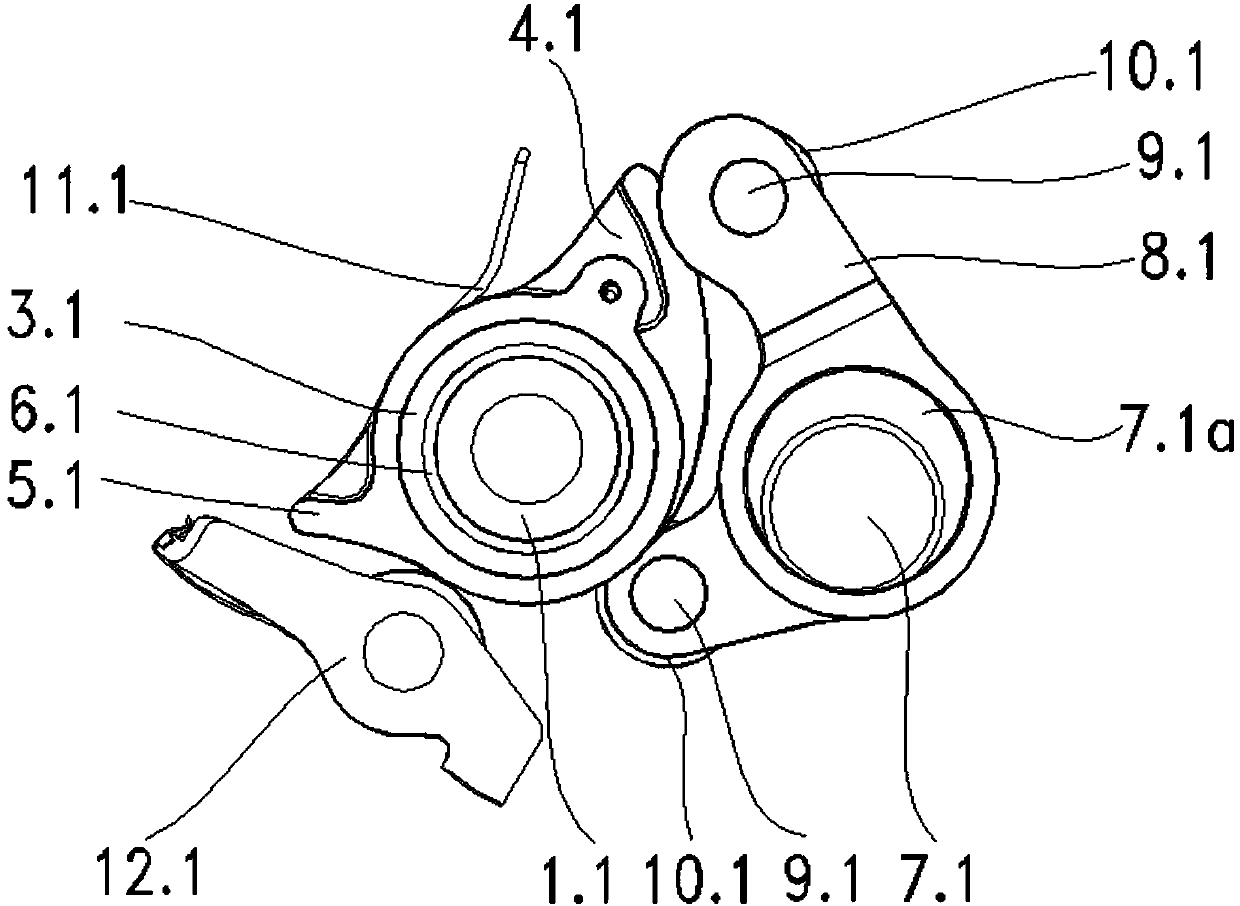

[0057] Implementation mode one: if Figure 2-15 As shown, a mechanism that can continuously change the valve lift includes camshaft I1.1, cam I2.1, control shaft I7.1 and rocker arm I12.1, and camshaft I1.1 is located on cam I2.1- The side empty sleeve has a swing camshaft 3.1, the main swing cam 4.1 and the auxiliary swing cam 5.1 are arranged on the swing camshaft 3.1, the main swing cam 4.1 is provided with a main input end 4.1a and a main output end 4.1b, and the auxiliary swing cam 5.1 The auxiliary output end 5.1b is set at the same horizontal position as the main output end 4.1b; the eccentric shaft section I7.1a is set on the control shaft I7.1, and the control arm I8.1 and the control arm I8.1 are set on the eccentric shaft section I7.1a. 1 is provided with an input rod I 8.1a and an output rod I 8.1d; the outer end of the input rod I 8.1a of the cam I 2.1 and the control arm I 8.1 is offset, and the outer end of the output rod I 8.1d is in contact with the main swing...

Embodiment approach 2

[0064] Implementation mode two: if Figure 17-33 As shown, a mechanism that can continuously change the valve lift includes camshaft II 1.2, cam II 2.2, control shaft II 6.2 and rocker arm II 15.2, and two swing cams 3.2 are centered on cam II 2.2 It is left-right symmetrical and arranged on the camshaft II1.2 in the form of clearance fit. The swing cam 3.2 is provided with an input end 3.2a and an output end 3.2b; an eccentric shaft section II6.2a is set on the control shaft II6. Ⅱ6.2a is provided with a control arm Ⅱ7.2, and the control arm Ⅱ7.2 is provided with an input rod Ⅱ7.2a and two output rods Ⅱ7.2b; the cam Ⅱ2.2 and the input rod Ⅱ7.2a of the control arm Ⅱ7.2 The outer ends offset each other, the outer ends of the two output rods II 7.2b offset the input ends 3.2a of the two swing cams 3.2 respectively, and the two output ends 3.2b offset the two rocker arms II 15.2 respectively.

[0065] combine Figure 22 , Figure 25 and Figure 31-33 As shown, the input ends ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com