Indoor self-power-generating strong-exhaust wind power generation structure

A self-generating and wind wheel technology, applied in the direction of wind turbines, wind motor combinations, installation/support configuration of wind turbines, etc., can solve the problems of large space occupation, poor flexibility, and inability to complete indoors, etc. The effect of faster rotation and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

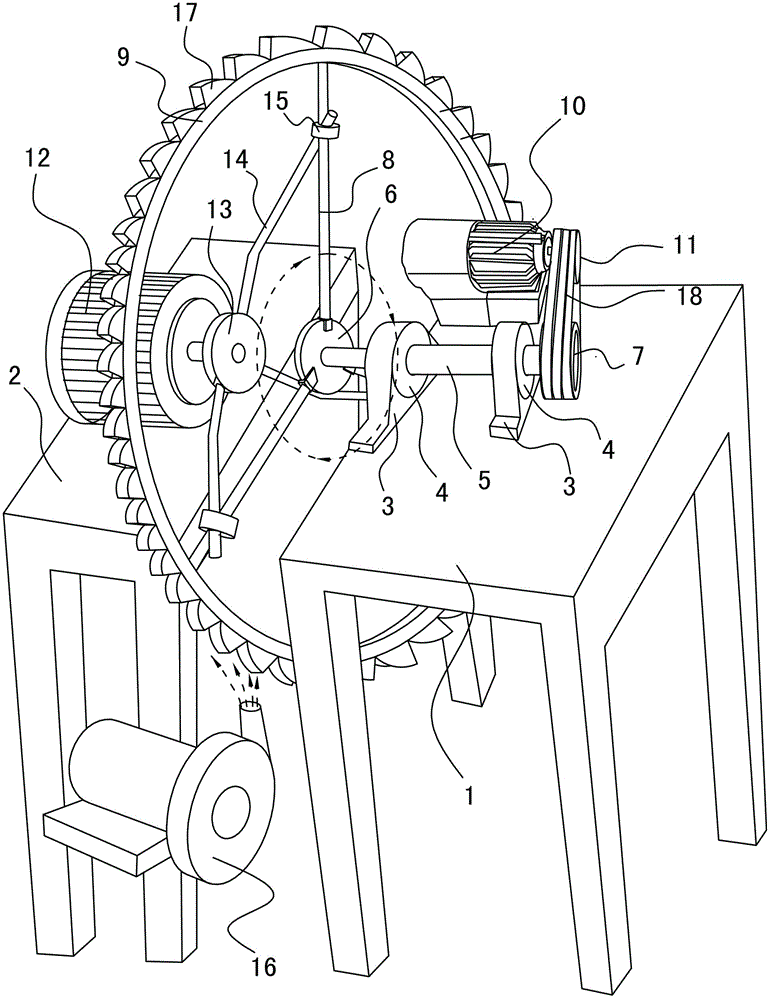

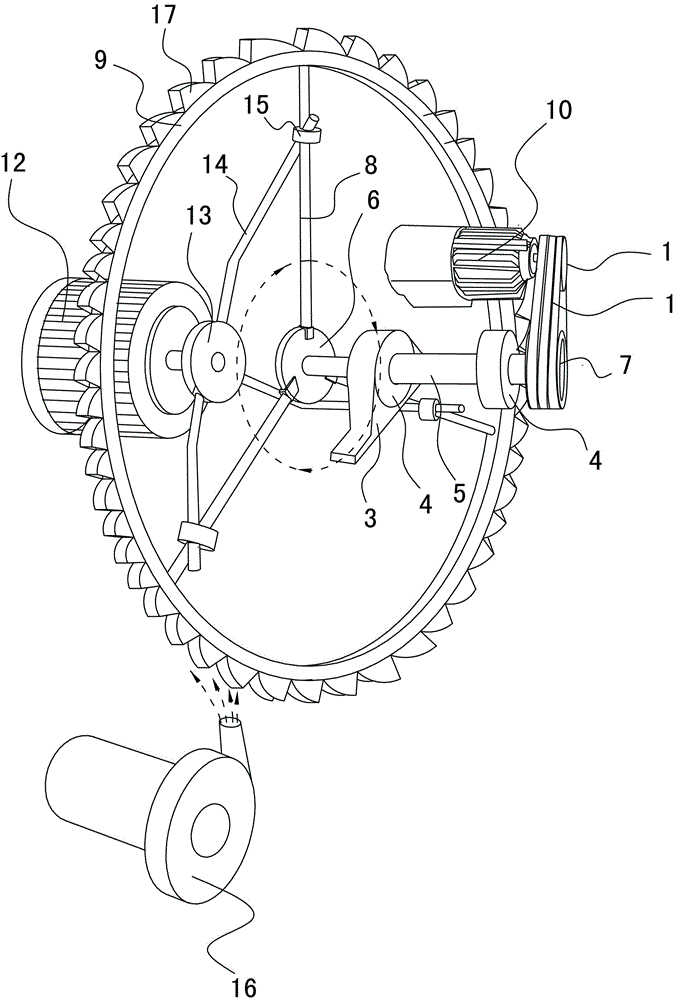

[0012] Such as figure 1 with 2 As shown, the self-generating indoor strong exhaust wind power generation structure proposed by the present invention includes a first table support 1 and a second table support 2 correspondingly arranged, and a pair of rotating bearing supports 3 is arranged on the first table support 1, and the two The inside of the rotating bearing support 3 is provided with a rotating bearing 4, and a rotating shaft core 5 is installed between the two rotating bearings 4, and a wind wheel mounting plate 6 is installed on one end of the rotating shaft core 5, and the other end of the rotating shaft core 5 A driven belt pulley 7 is installed, and the wind wheel mounting plate 6 is equipped with a plurality of wind wheel support rods 8, and the wind wheel support rods 8 are equipped with a rotation mechanism arranged between the first table su...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap