Guide mechanism of labyrinth compressor piston

A technology of guiding mechanism and compressor, which is applied in the direction of machines/engines, mechanical equipment, liquid variable capacity machinery, etc., can solve problems affecting the efficiency of labyrinth compressors, achieve the effect of compact structure, simple structure, and improved straightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

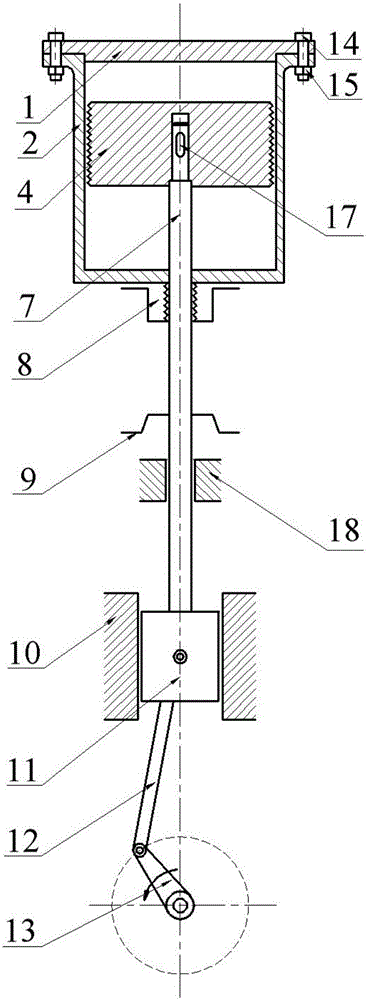

[0022] Embodiment 1: as figure 2 and image 3 As shown, the spherical ceramic ball 5 is arranged on the cover side of the piston 4 of the labyrinth compressor.

Embodiment 2

[0023] Embodiment 2: as Figure 4 As shown, the spherical ceramic ball 5 is arranged on the shaft side of the piston 4 of the labyrinth compressor.

[0024] As a preferred embodiment of the present invention, the piston 4 of the labyrinth compressor and the piston end cover 6 are connected by screws 19 .

[0025] The present invention adopts the spherical ceramic ball 5 as the key guide element of the piston 4 of the labyrinth compressor, without lubrication and without setting the guide bearing 18, which not only makes the structure of the labyrinth compressor more compact, but also improves the straightness of the piston operation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com