Anti-clogging device for sewage pump

A technology for sewage and water inflow, which is applied to components, pumps, pump components, etc. of pumping devices used for elastic fluids. It can solve the problem of ineffective filtering or cutting refinement, sewage pumps that cannot guarantee operation, and pumps that cannot work normally. Work and other problems, to achieve the effect of improving stability, reducing the possibility of clogging, and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

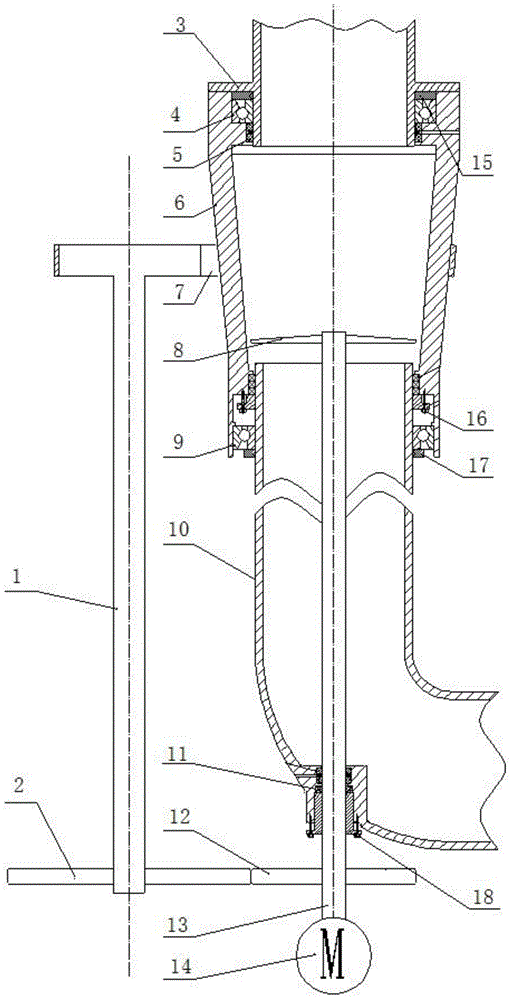

[0026] An anti-blocking device for a sewage pump, comprising a connecting rod 1 with a tension wheel, a driven gear 2, a water inlet pipe 3, a rotating mechanism 6, a belt 7, a cutting blade 8, an outlet pipe 10, a driving gear 12, and a drive shaft 13 , drive motor 14;

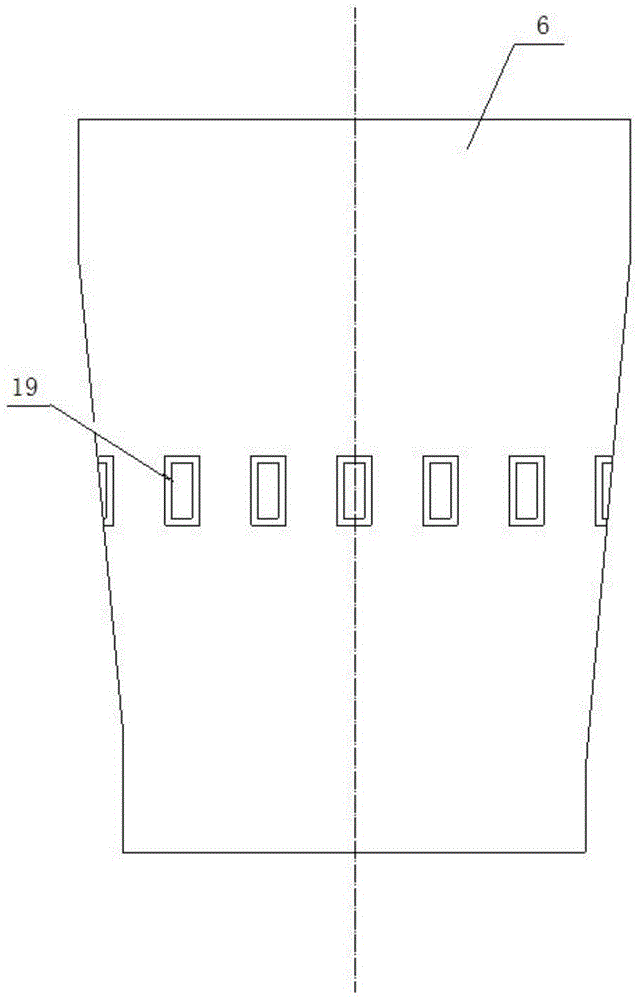

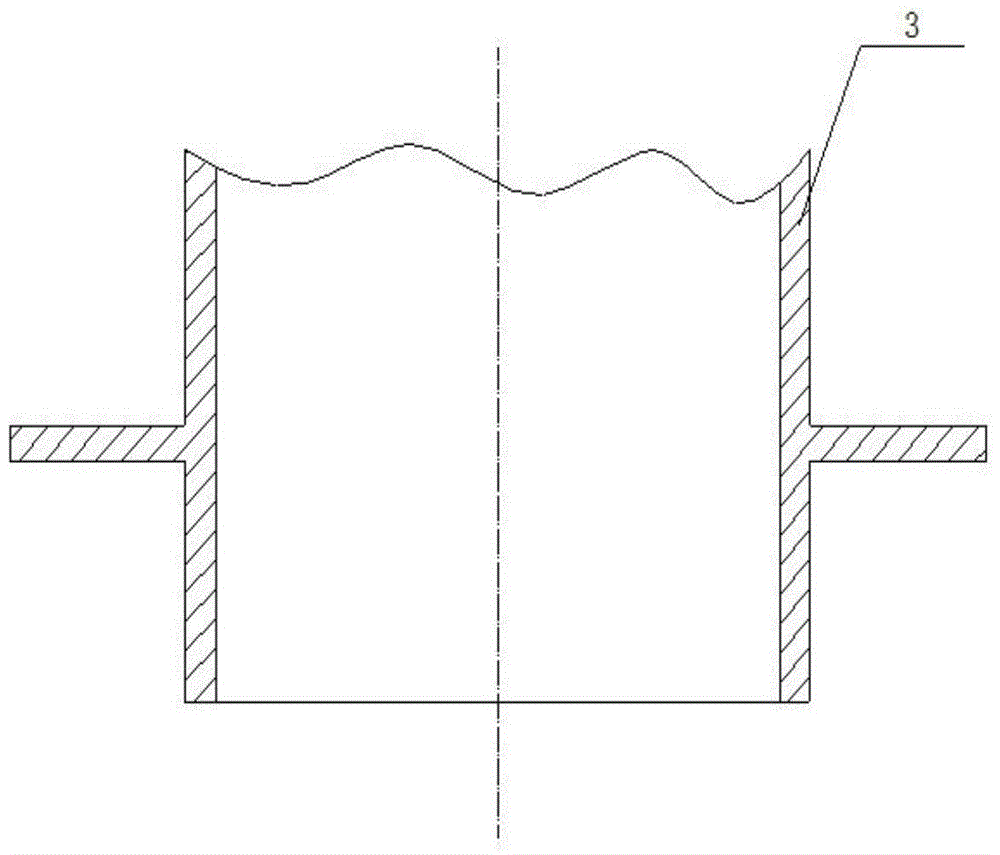

[0027] The water inlet pipe 3 is connected to the inlet end of the rotating mechanism 6 through the bearing A4; the outlet end of the rotating mechanism 6 is connected to the water outlet pipe 10 through the bearing B9, and the rotating mechanism 6 is a hollow structure; The protrusion of the water pipe 3 and the protrusion of the inlet end of the rotating mechanism 6 cooperate to determine the position of the bearing A4, and the outer sleeve 15 is set on the water inlet pipe 3 and placed between the bearing A4 and the protrusion of the water inlet pipe 3; 6 The outlet end is connected to the water outlet pipe 10 through the bearing B9; the round nut 17 is combined with the thread on the water outlet pipe 10,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com