Energy-saving pneumatic muscle tendon with functions of internal linear motion guiding and automatic resetting

A fluidic muscle, linear motion technology, applied in the direction of fluid pressure actuating devices, etc., can solve problems such as restricting popularization and application, and achieve the effect of expanding application fields and compact overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In the following, the two technical solutions of the present invention will be further elaborated in conjunction with the drawings of two specific embodiments.

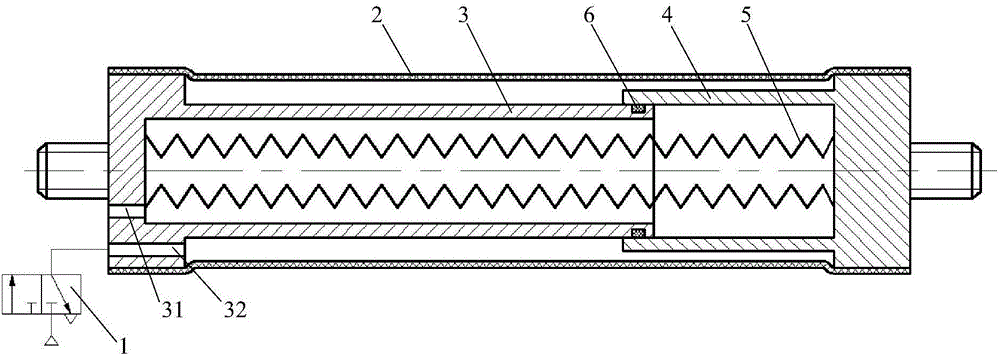

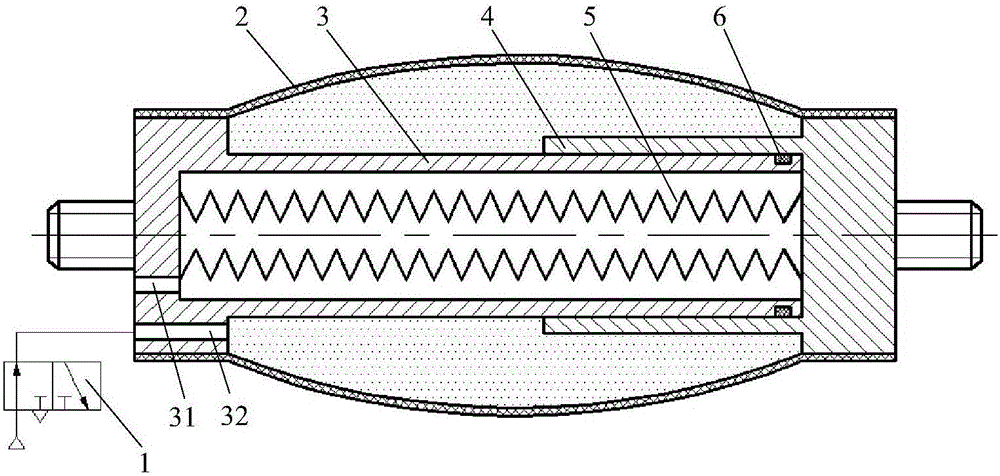

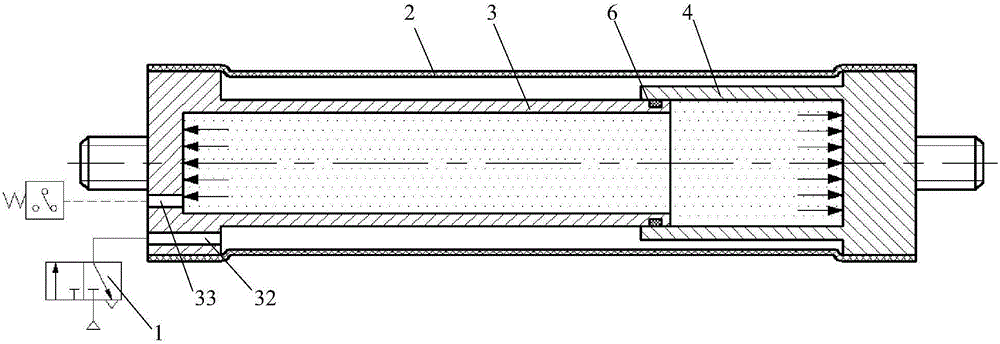

[0016] attached figure 1 with attached figure 2 Shown is a specific embodiment of a technical solution of the present invention. It can be seen from the figure that the pneumatic muscle is composed of a rubber tube 2 and a left nest 3 and a right nest 4 fixed at both ends of the inner hole; the left end of the left nest 3 has a breathing hole 31 and the air intake and exhaust of the working chamber. Hole 32. The outer surface of the right part of the left nesting part 3 is inserted into the inner hole of the left part of the right nesting part 4, and cooperates with each other to slide and nest to form an internal linear motion guide. The inner holes of the left nesting part 3 and the right nesting part 4 form an inner cavity, and a compression spring 5 is arranged in the inner cavity to form an automatic r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com