Fluidized bed boiler external bed cyclone fluidization system

A fluidized bed boiler and fluidized system technology, which is applied in the system field of cyclone distribution and fluidization of boiler circulating materials by an external bed of a fluidized bed boiler, can solve the problem of insufficient heat exchange, unevenness, and fluidized air arrangement. Unreasonable and other problems, to achieve the effect of rapid load adjustment, improve thermal efficiency, and improve load response rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

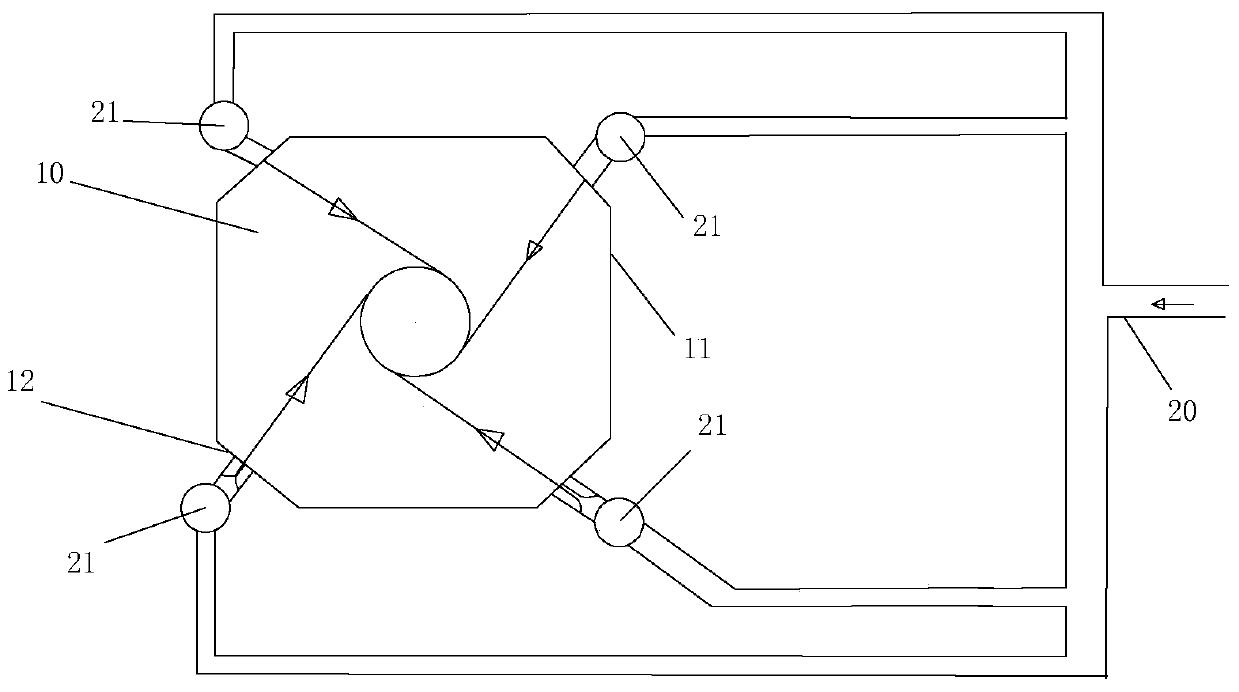

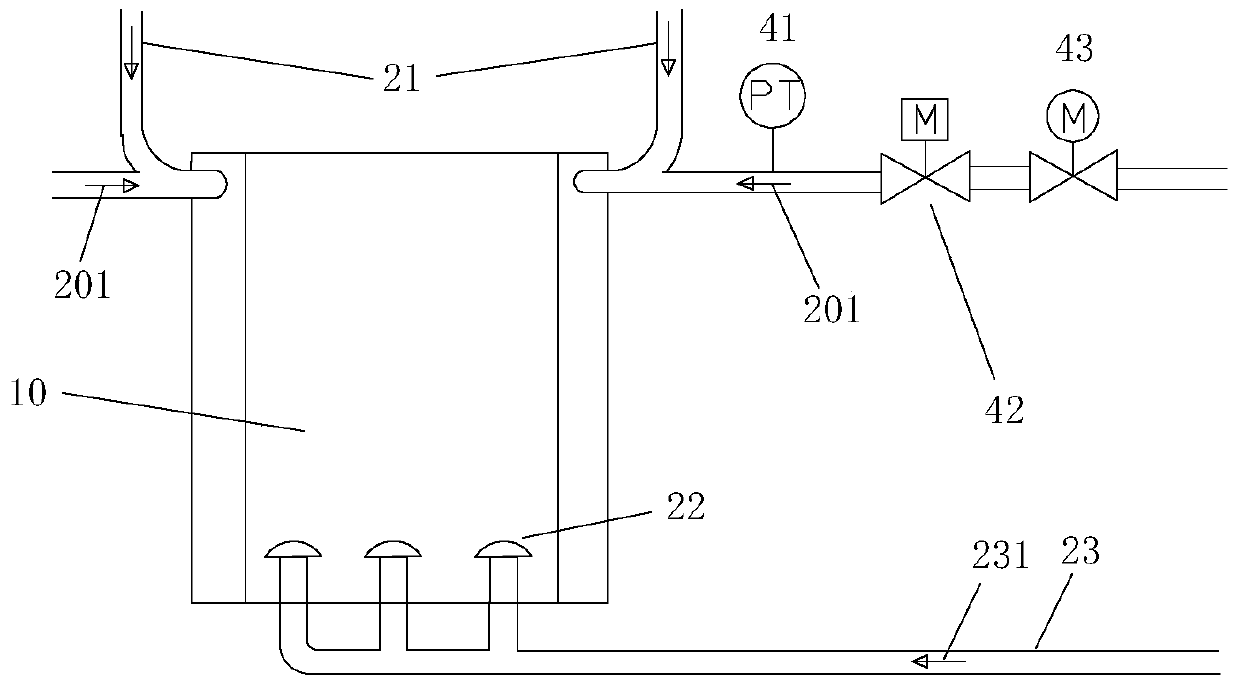

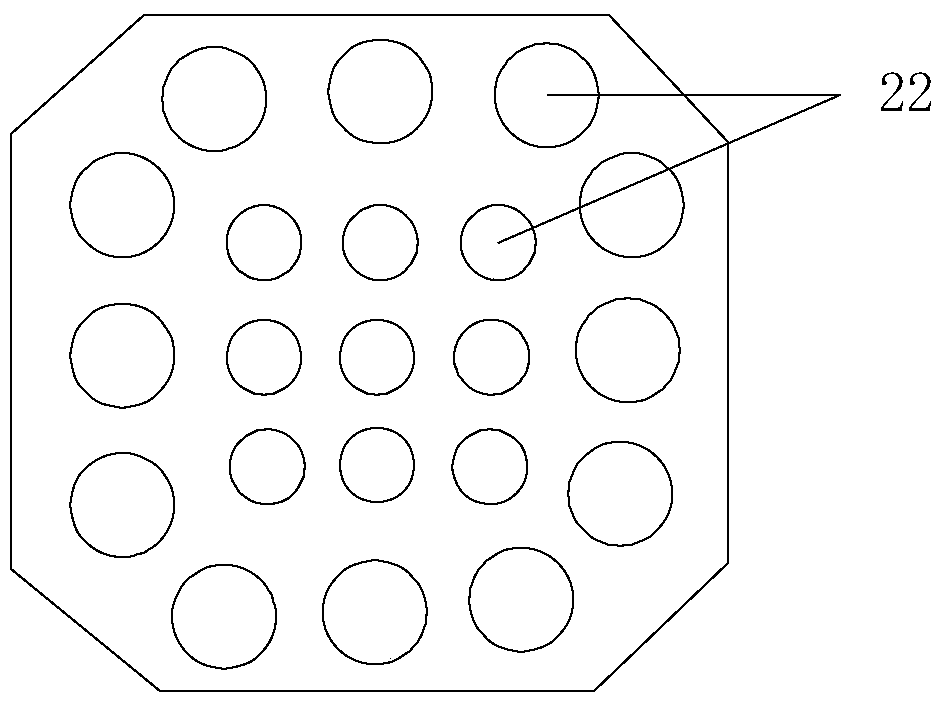

[0042] In order to make the technical characteristics and effects of the present invention more obvious, the technical solution of the present invention will be further described in conjunction with the accompanying drawings. There is no limitation, as long as the jet flow emitted from the fluidization air duct can form an inscribed circular fluidization swirl in the external bed cavity, the jet flow mentioned here refers to the high-temperature circulating particles carried by the fluidization wind. At the same time, the present invention does not limit the shape of the external bed cavity, nor does it limit the specific size and layout of the bell type fluidization hood involved. In addition, what is shown in the drawings is a simplified and schematic representation, and the dimensions of the elements in the drawings do not conform to the actual scale.

[0043] as attached figure 1 shown, with figure 1 It is a top view of a cyclone fluidization system with an external bed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com