Laser emitting apparatus

A laser emission and laser technology, used in measuring devices, instruments, mapping and navigation, etc., can solve problems such as reduced work efficiency, non-parallel, and inability to guarantee accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

[0053] The present invention proposes a laser emitting device, which can emit a high-precision horizontal projection line L1 parallel to the horizontal plane through adjustment, and can also adjust the height of the horizontal projection line L1 as required.

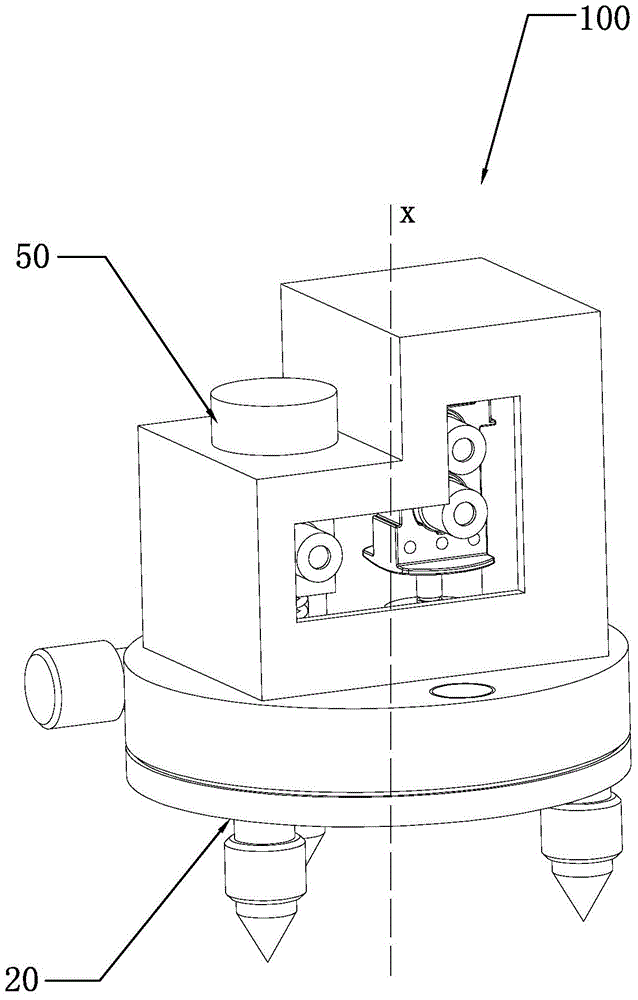

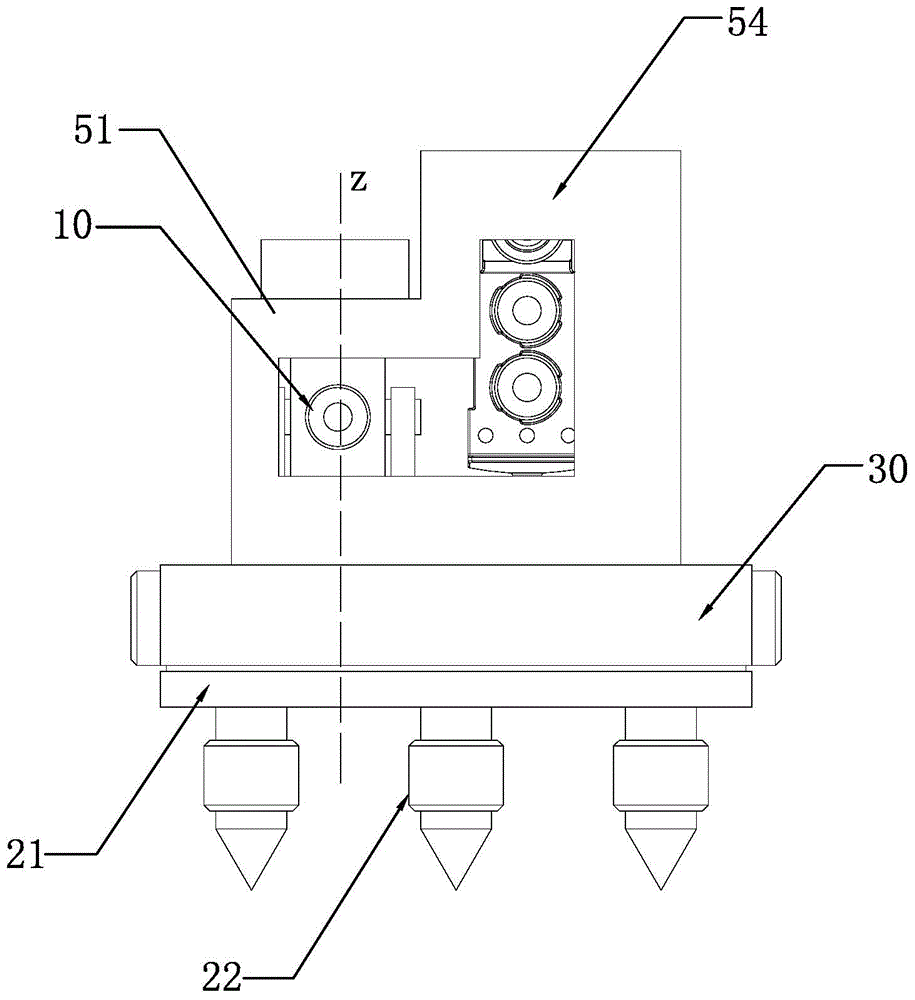

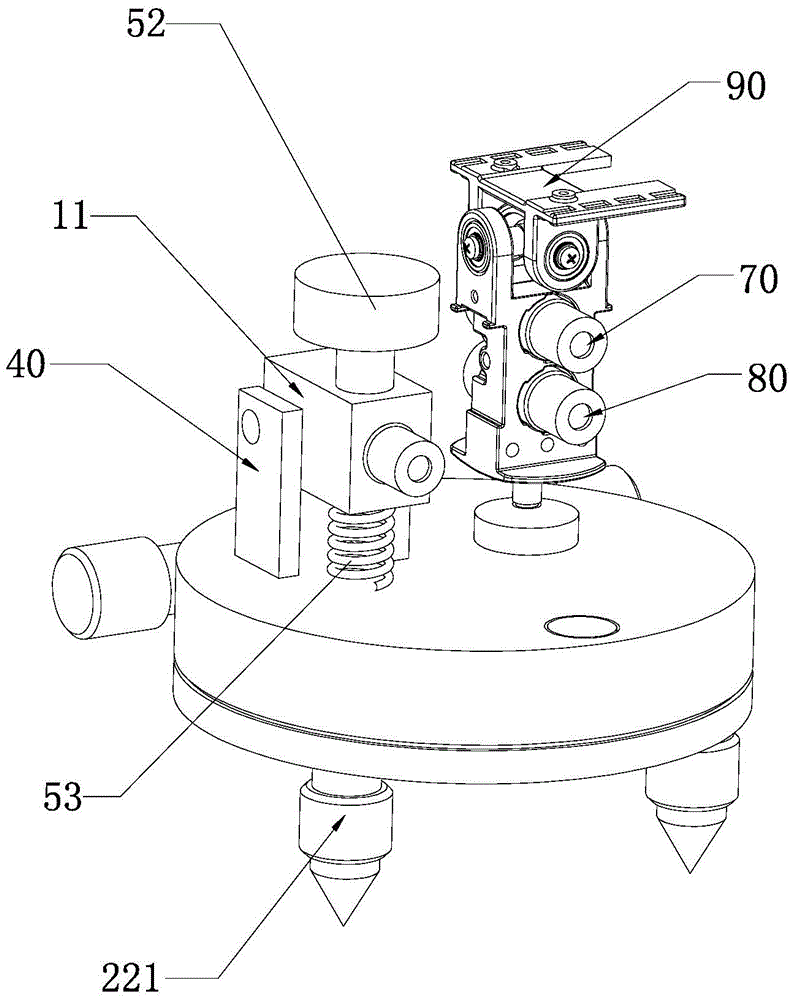

[0054] Figure 1 to Figure 5 Shown is the structure of the first embodiment of the laser emitting device 100 of the present invention, please refer to Figure 1 to Figure 5 , the laser emitting device 100 of the present invention at least includes: a first light source assembly 10 , a support assembly 20 , a rotating disk 30 , a connection assembly 40 , a height adjustment assembly 50 and a fine adjustment assembly 60 .

[0055] The first light source assembly 10 can emit a laser surface covering a first preset angle range, that is to say, the laser surface presents an angle shape,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com