A unidirectional stress sensor based on a liquid metal antenna and a method for preparing the same

A liquid metal, one-way stress technology, applied in instruments, force measurement, force/torque/work measuring instruments, etc., can solve the problems of landslide monitoring errors, easy breakage and damage, weak strength of elastic shell joints, etc. Improved reliability, improved accuracy, less damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

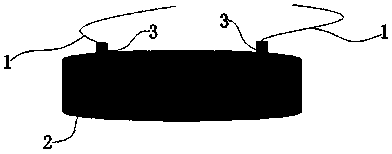

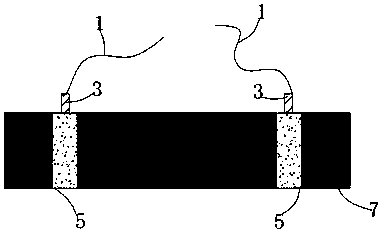

[0035] Such as figure 1 and figure 2 As shown, the unidirectional stress sensor based on the liquid metal antenna of the present invention includes a cylindrical box body 2, and two compressible organic polymer cylinders 5 are arranged inside the cylindrical box body 2, and the organic polymer cylinder 5 The length is the distance between the upper and lower opposite surfaces of the cylindrical box body, and the interior of the cylindrical box body 2 is filled with filling material 7;

[0036] Such as figure 1 and Figure 4 As shown, each organic polymer cylinder 5 is provided with a microchannel 4, the microchannel 4 is filled with liquid metal, the liquid metal in the microchannel is electrically connected to the coaxial feeder 1, and the coaxial feeder 1 is packaged from the box body Extracted from object 3.

[0037] In this embodiment, the filling m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com