Super-high-temperature electromagnetic acoustic sensor and obtaining method thereof

An electromagnetic ultrasonic and acquisition method technology, which is applied in the direction of material analysis, instruments, and scientific instruments using sound waves/ultrasonic waves/infrasonic waves, and can solve problems such as difficult to detect high-temperature equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

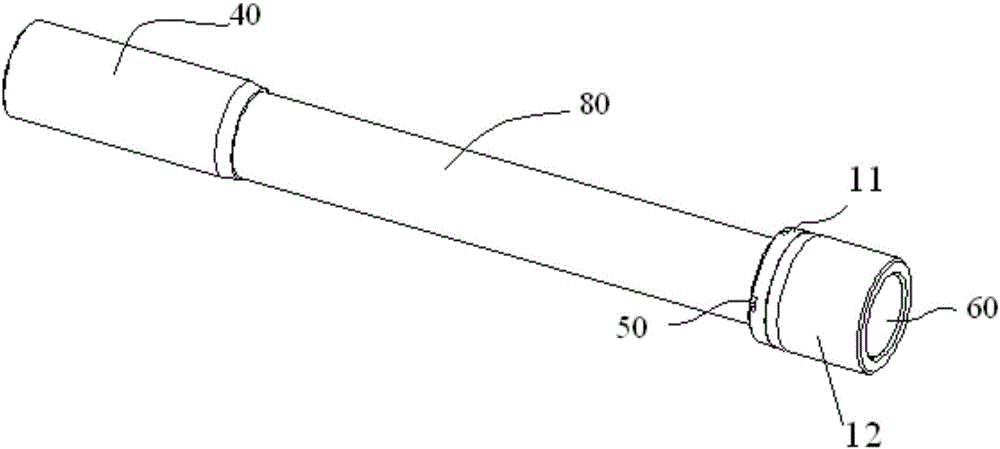

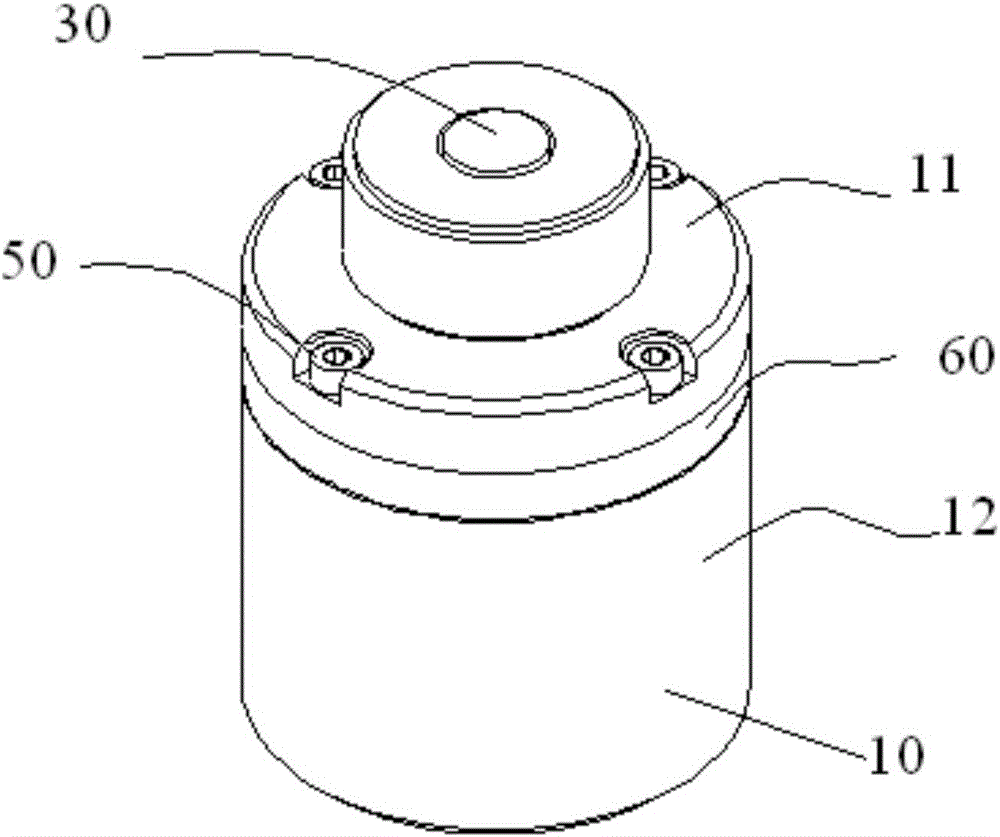

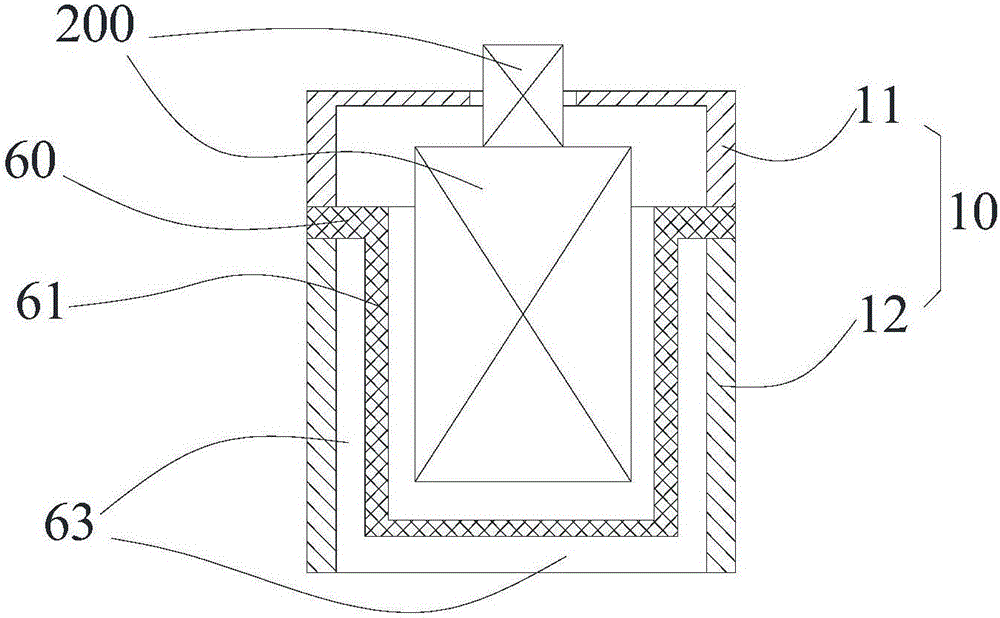

[0035] Such as Figure 1 to Figure 4 As shown, in Embodiment 1 of the present invention, the ultra-high temperature electromagnetic ultrasonic sensor includes a housing 10 , a sensor assembly 200 and a heat insulation structure 60 . The sensor assembly 200 includes a magnet and coil assembly 20 and a signal connector 30 . The magnet and coil assembly 20 is arranged inside the housing 10; the signal connector 30 is connected to the coil connector of the magnet and coil assembly 20; the heat insulation structure 60 is arranged inside the housing 10 and is located between the housing 10 and the magnet and coil assembly 20 between.

[0036] Through the above settings, the heat insulation structure 60 can delay the heat conduction of the high-temperature equipment to the inside of the housing 10 for a certain period of time, thereby protecting the sensor components 200 such as the magnet and the coil component 20 inside the housing 10 from being damaged by high temperature. When ...

Embodiment 2

[0099] In the second embodiment of the present invention, the difference between the second embodiment and the first embodiment is that the heat insulation structure 60 is one or more layers of heat insulation pads arranged on the side of the casing 10 facing the device under test. The heat insulation pad is fixedly connected with the housing 10 . This heat insulation pad is made of high temperature resistant material. The shape of the heat insulation pad is adapted to the inner shape of the casing 10 .

[0100] From the above description, it can be seen that the above-mentioned embodiments of the present invention have achieved the following technical effects: the heat insulation structure can delay the heat conduction of the high-temperature equipment to the inside of the housing for a certain period of time, thereby protecting the magnets and Coil components and other components are protected from high temperature damage, so that when the ultra-high temperature electromagn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com