Mounting device for pressure fluctuation sensor and combustion chamber equipped with the same

A technology of fluctuation sensor and installation device, applied in the direction of combustion chamber, continuous combustion chamber, combustion method, etc., can solve the influence of the stability and safety of the sensor cable 10 of the sensor body, the deviation of signal frequency, amplitude and phase, and high temperature. Air intrusion and other problems can reduce the possibility of shaking and damage, reduce the impact and prolong the service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

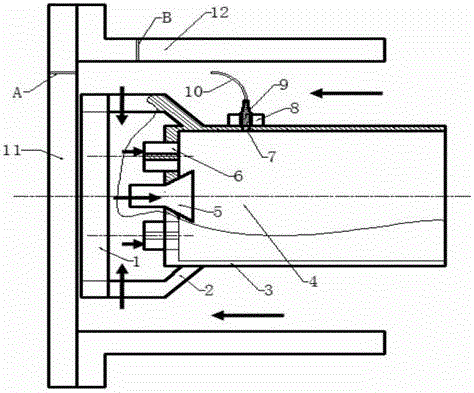

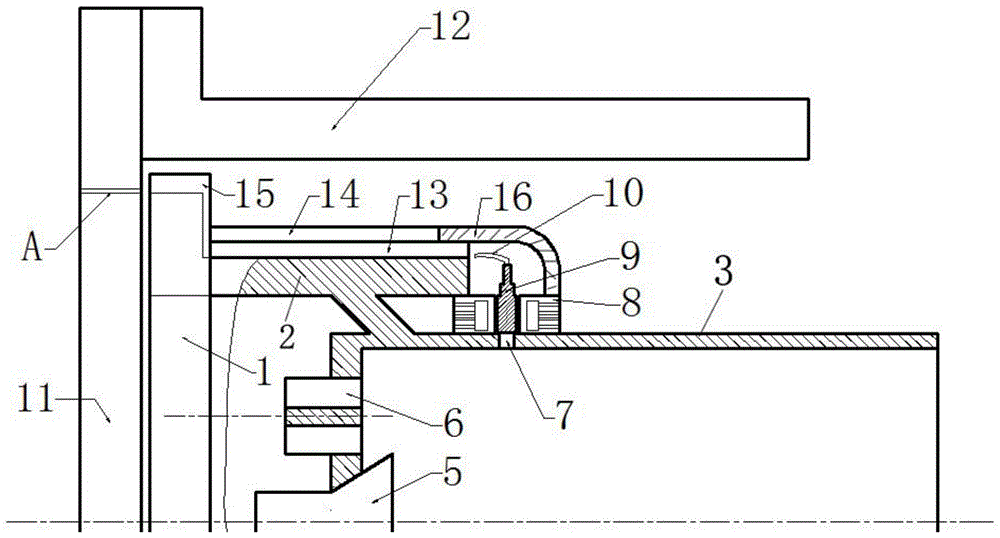

[0031] Such as Figure 2~6 As shown, the installation device of this embodiment includes an installation seat 8 and an airflow baffle 16 .

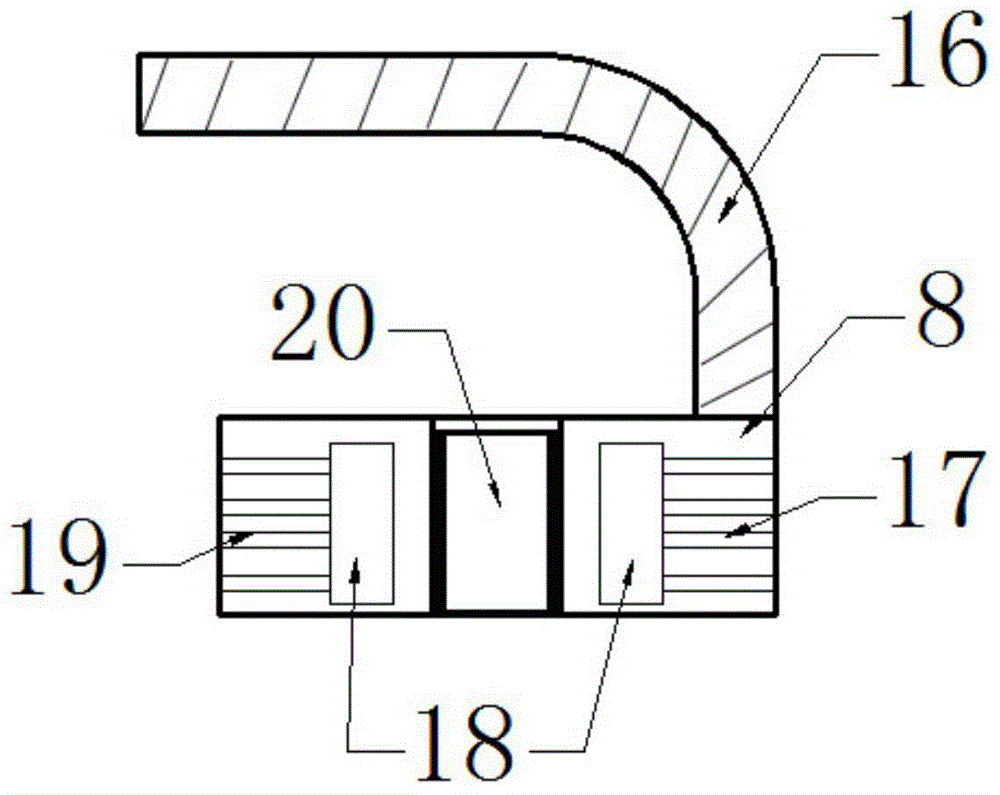

[0032] There is a screw hole 20 for fixing the sensor 9 on the mounting base 8. A cooling cavity 18 is also provided inside the mounting base 8. The cooling cavity 18 is located near the screw hole 20 and is arranged around the screw hole 20. It is annular and is a cooling ring cavity. One side of the ring chamber communicates with the outside world through the air inlet 17, and the other side communicates with the outside world through the air outlet 19. Both the air inlet 17 and the air outlet 19 have multiple, so as to reduce the aperture of a single hole, which is conducive to increasing the wind speed , to speed up the cooling rate.

[0033]The airflow baffle 16 is installed on the top surface of the mounting base 8, and the windward side of the airflow baffle 16 is positioned at the same side of the screw hole 20 as the air inlet 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com