Ultrahigh-temperature-resistant electromagnetic ultrasonic transducer with double-coil structure

A double-coil structure, electromagnetic ultrasonic technology, applied in the use of ultrasonic/sonic/infrasonic, ultrasonic/sonic/infrasonic generation, using sound/ultrasonic/infrasonic to analyze solids, etc., can solve low temperature, poor signal-to-noise ratio, etc. problems, to avoid high temperature damage, reduce the low signal-to-noise ratio of ultrasonic signals, and reduce the effect of lifting distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

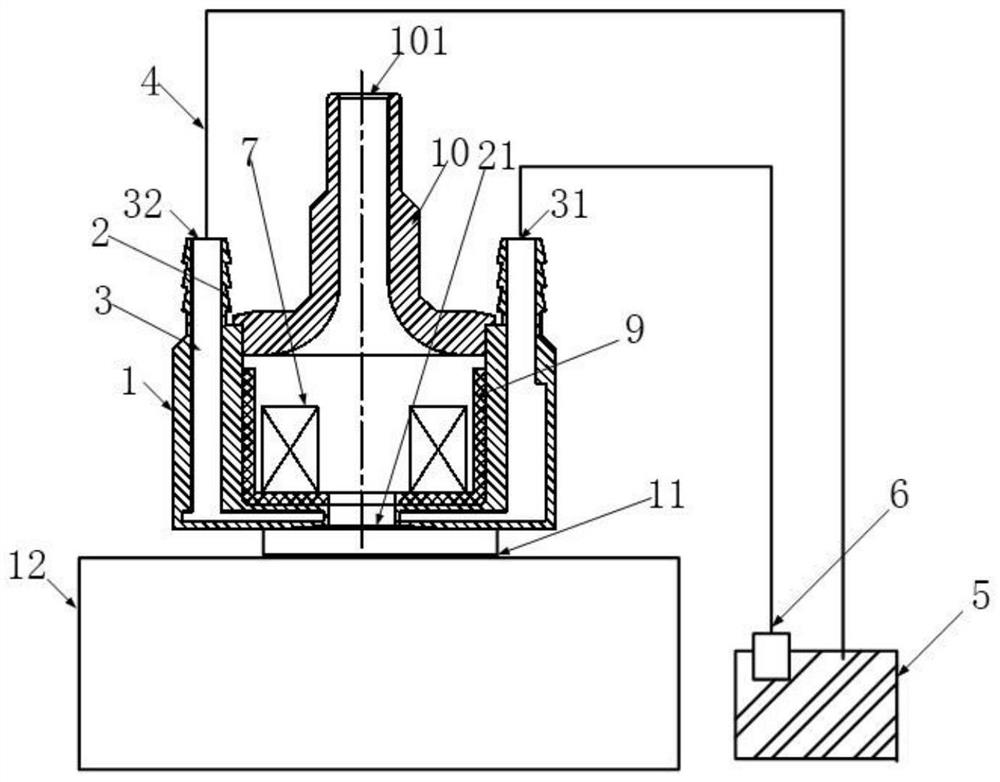

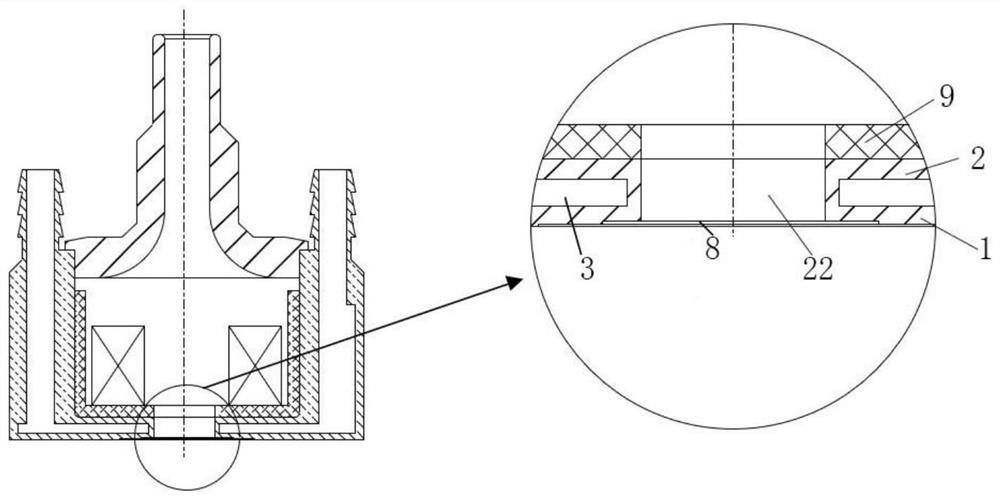

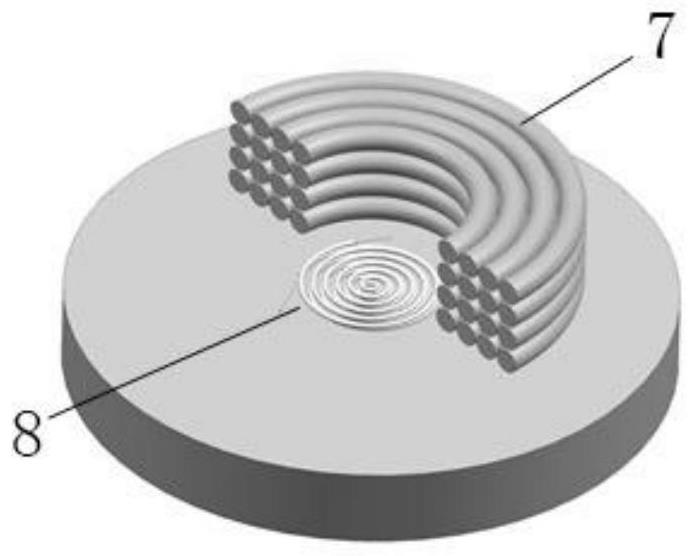

[0031] An electromagnetic ultrasonic transducer with a double-coil structure resistant to ultra-high temperature, including a water cooling system and a probe assembly, such as figure 1 and 2 As shown, the water cooling system includes an outer casing 1 and an inner casing 2 integrally connected, the outer casing 1 and the inner casing 2 are both cylindrical barrel structures, and the side walls of the outer casing 1 and the inner casing 2 are A cavity 3 is left between the cavity and the bottom, and one end of the upper surface of the cavity 3 is provided with a water inlet 31, and the other end is provided with a water outlet 32, and the water inlet 31 and the water outlet 32 are all communicated with the water tank 5 through the water pipe 4, The water pipe 4 connected to the water inlet 31 is provided with a water pump 6, the bottom of the outer shell 1 is provided with a groove I21 upward, and the probe assembly includes an excitation coil 7 and an eddy current coil 8, ...

Embodiment 1

[0048] Since the excitation magnetic field is mainly in the horizontal direction, the combination of the excitation coil 7 and the eddy current coil 8 generates a transverse wave, and 45# steel is used as the test object to verify the feasibility of the ultra-high temperature resistant EMAT water cooling system.

[0049] In the experiment, the heating furnace was set to be heated to the specified temperature for 20 minutes. After holding the heat for 20 minutes, the echo signal was collected from the tested block 11. The echo signal obtained by the experiment result was as follows: Figure 8 As shown, the temperature in the figure refers to the temperature in the furnace cavity, and the temperature of the tested block 11 is slightly lower than the temperature in the furnace cavity, which is due to the local cooling of the tested block 11 by the water cooling system. Experiments show that the probe of the electromagnetic ultrasonic transducer with ultra-high temperature resistan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com