Heat recovery device

A heat recovery device and heat preservation box technology, applied in lighting and heating equipment, steam generation method using heat carrier, steam boiler accessories, etc., can solve the problems of heat waste, 3-4 hours, or even longer.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

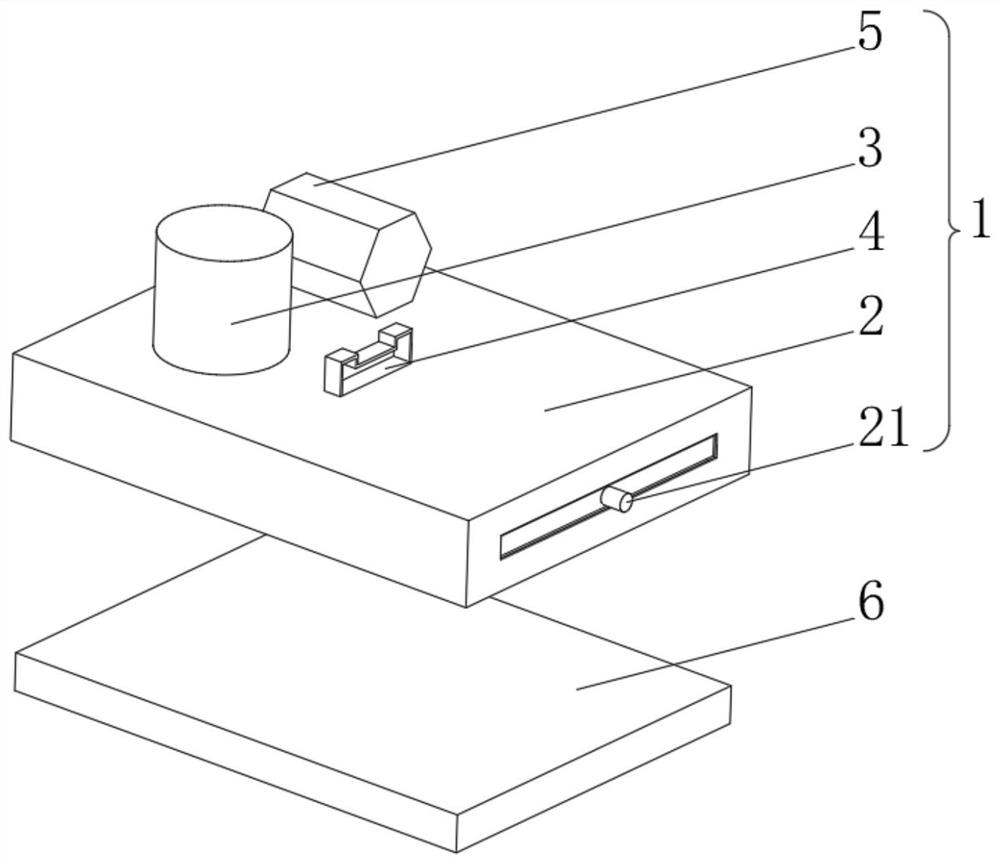

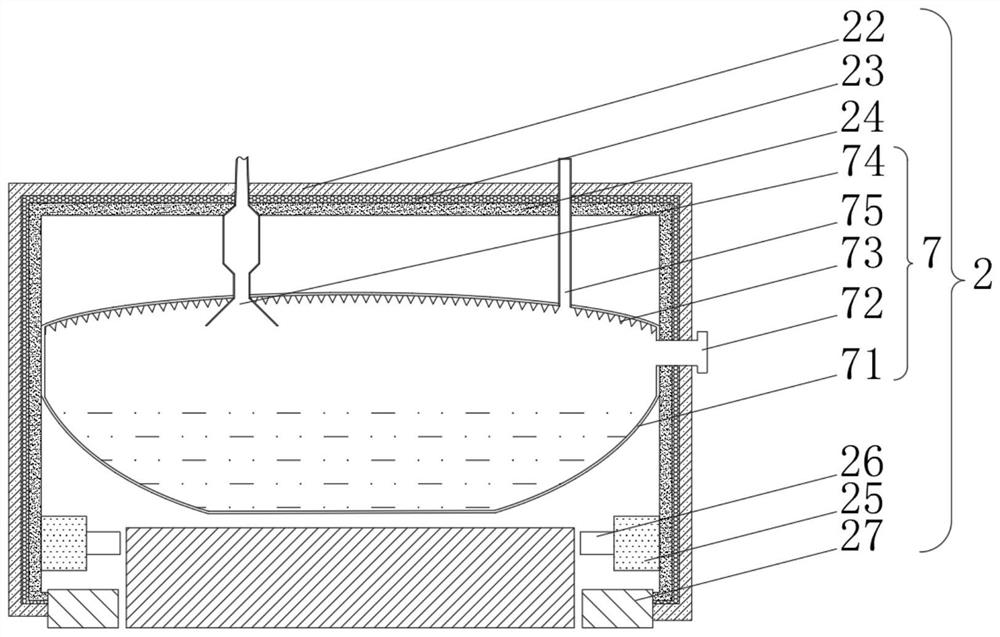

[0040] see Figure 1-3 The present invention provides a technical solution: a heat recovery device, including a heat recovery device body 1 composed of an incubator 2, a steam engine 3, a handle 4 and a generator 5, the bottom of the steam engine 3, the bottom of the handle 4 and the generator 5 The bottom is fixedly connected with the top of the incubator 2, the generator 5 is connected with the external storage battery, the steam engine 3 is connected with the generator 5, the right side of the incubator 2 is connected with a rotary switch 21, and the right side of the incubator 2 is provided with a The mold 6 is heated, and the incubator 2 includes an outer frame 22. The inner wall of the outer frame 22 is fixedly connected with an insulating cotton 23. The inner wall of the insulating cotton 23 is fixedly connected with a hydraulic shell 24. The inside of the hydraulic shell 24 is filled with insulating oil. The oil guide pipe 25 is connected inside, and the oil guide pipe...

Embodiment 2

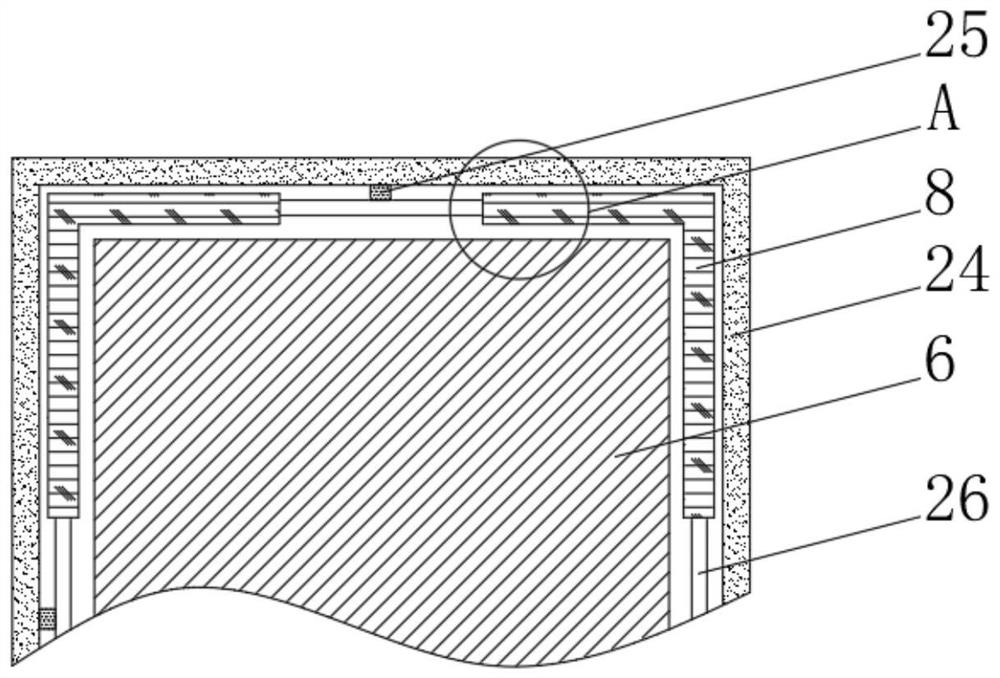

[0046] see Figure 1-5 On the basis of the first embodiment, the present invention provides a technical solution: the clamping block 82 includes a clamping frame 821, the outside of the clamping frame 821 is slidably connected to the inside of the connecting frame 81, and the bottom of the clamping frame 821 is connected by a hard The mass block is fixedly connected with an elastic piece 822 , the bottom of the elastic piece 822 is fixedly connected with an extruding block 823 , and the bottom of the extruding block 823 is fixedly connected with a sliding plate 824 .

[0047] The buffer mechanism 9 is fixedly connected to the bottom of the sliding plate 824 , and the outer side of the sliding plate 824 is slidably connected to the inner wall of the clamping frame 821 .

[0048] When in use, the insulating oil inside the hydraulic casing 24 is squeezed by the piston, flows into the oil guide pipe 25, flows into the movable pipe 26, and flows into the inside of the connecting fr...

Embodiment 3

[0050] see Figure 1-7 , On the basis of Embodiment 1 and Embodiment 2, the present invention provides a technical solution: the buffer mechanism 9 includes an inner push block 91, the inside of the inner push block 91 is fixedly connected with a spring 92, and the bottom end of the spring 92 is fixedly connected with a The bottom of the outer pushing block 93 and the inner pushing block 91 are fixedly connected with an inner block 94 , and the top of the inner pushing block 94 is fixedly connected with the inside of the inner pushing block 91 .

[0051] The inside of the embedded block 94 is fixedly connected with a linkage frame 95, and the bottom of the linkage frame 95 is fixedly connected with an anti-collision block 96, and the top of the anti-collision block 96 is fixedly connected with an elastic ball 97, and the top of the elastic ball 97 is connected with the inner block 94. The top of the inner wall is fixedly connected, and the bottom of the outer pusher block 93 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com