Current measurement device and method, and manufacture method of current measurement device

The technology of a current measuring device and manufacturing method, which is applied in the field of electronic information, achieves the effect of broad application prospect and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

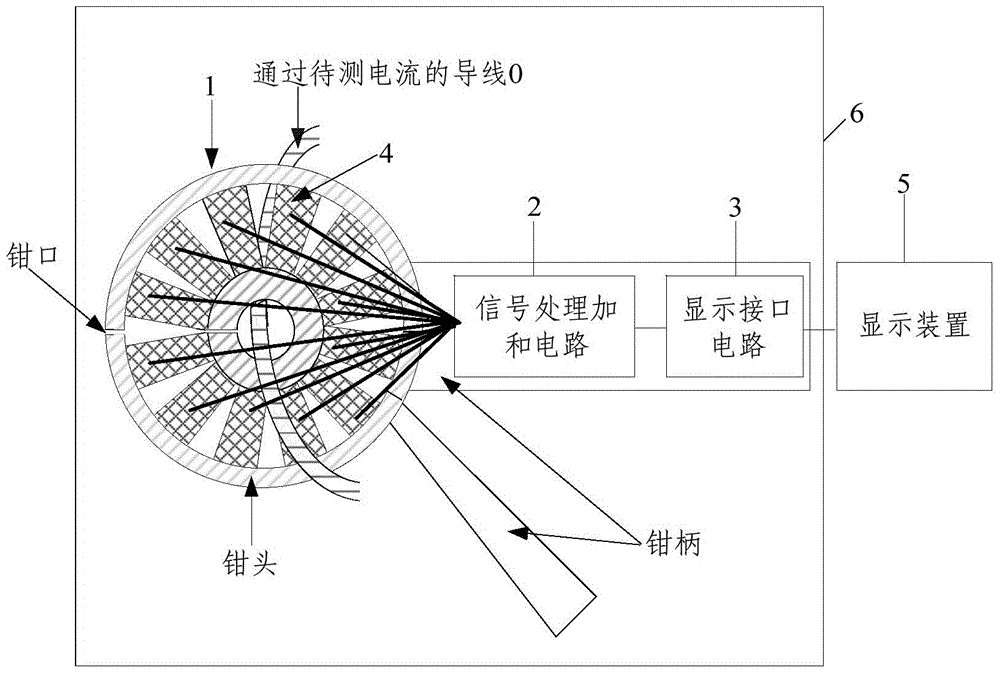

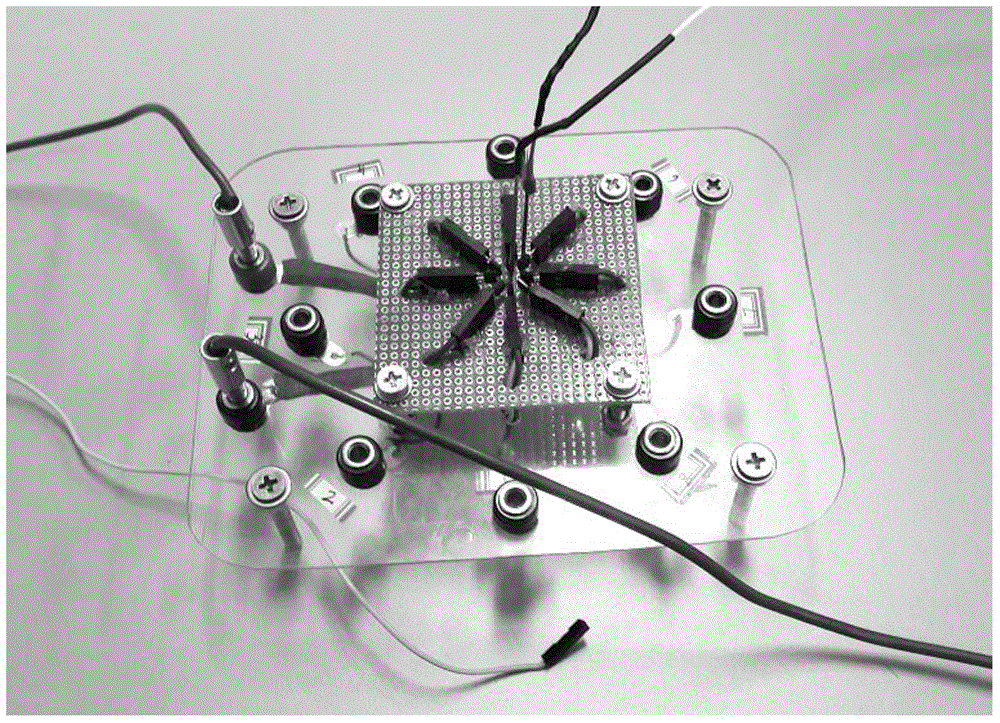

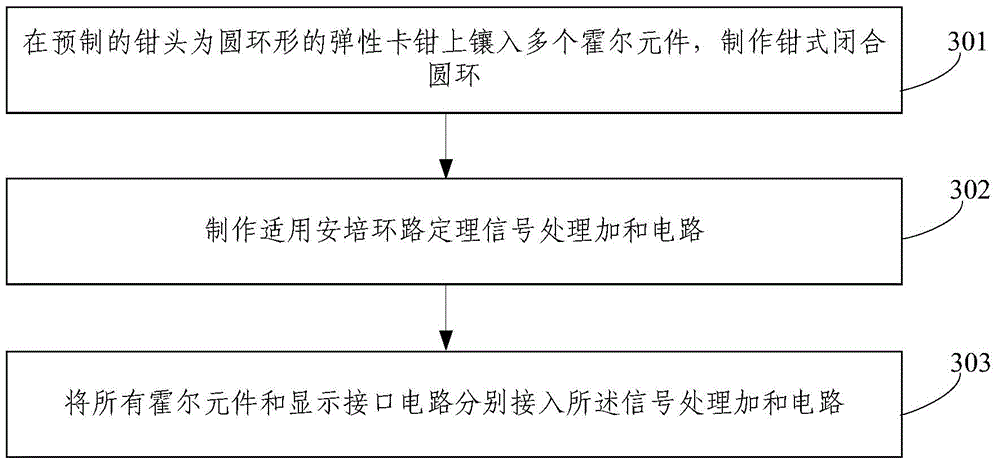

[0043] The specific embodiments of the present invention will be described in further detail below in conjunction with the drawings and embodiments. The following examples are used to illustrate the present invention, but not to limit the scope of the present invention.

[0044] The value of the current I to be measured in the embodiment of the present invention is calculated according to the Ampere’s Loop Theorem. The Ampere’s Loop Theorem is specifically: the value of the integral of the magnetic induction B in space along any closed path (ie the circulating current value of B) is equal to The permeability μ multiplied by the algebraic sum of the currents enclosed by the closed path, namely If the current flow is in a right-handed spiral relationship with the integral loop, the current takes a positive value, otherwise it takes a negative value.

[0045] Because the integrated magnetoelectric sensor is getting smaller and smaller, so that people can measure the spatial distribut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com