MMC module voltage measuring and fault locating method based on state monitoring

A technology of voltage measurement and voltage, which is applied in the direction of only measuring voltage, measuring current/voltage, measuring electricity, etc., and can solve problems such as increased system influence, hardware complexity, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

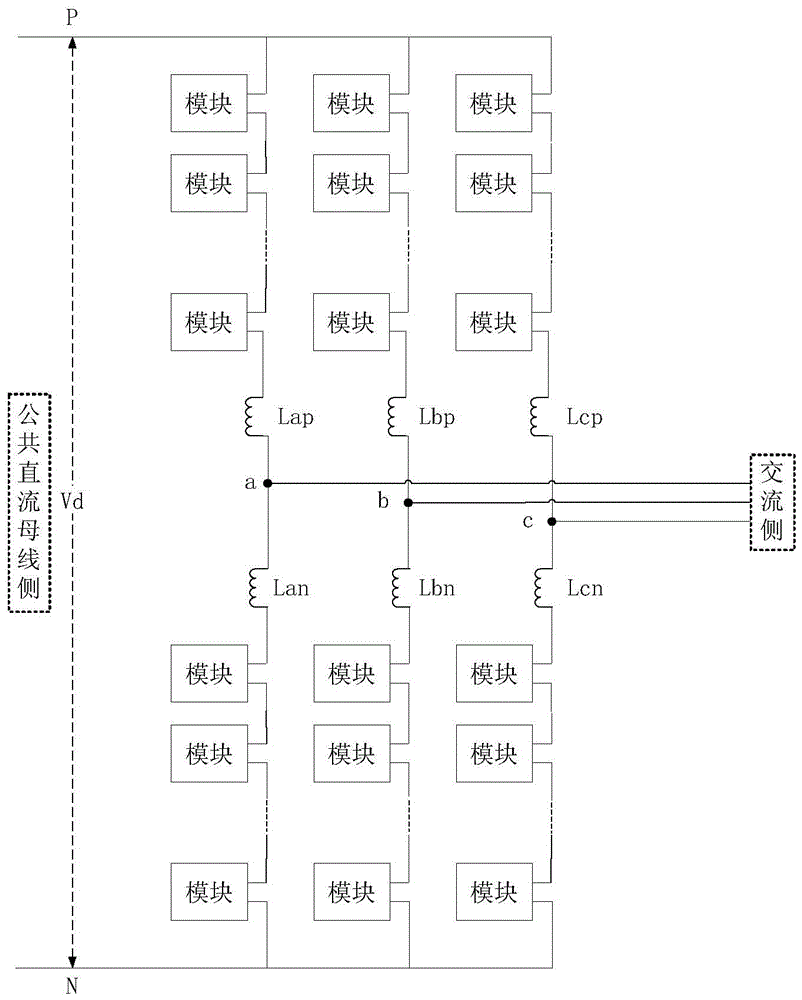

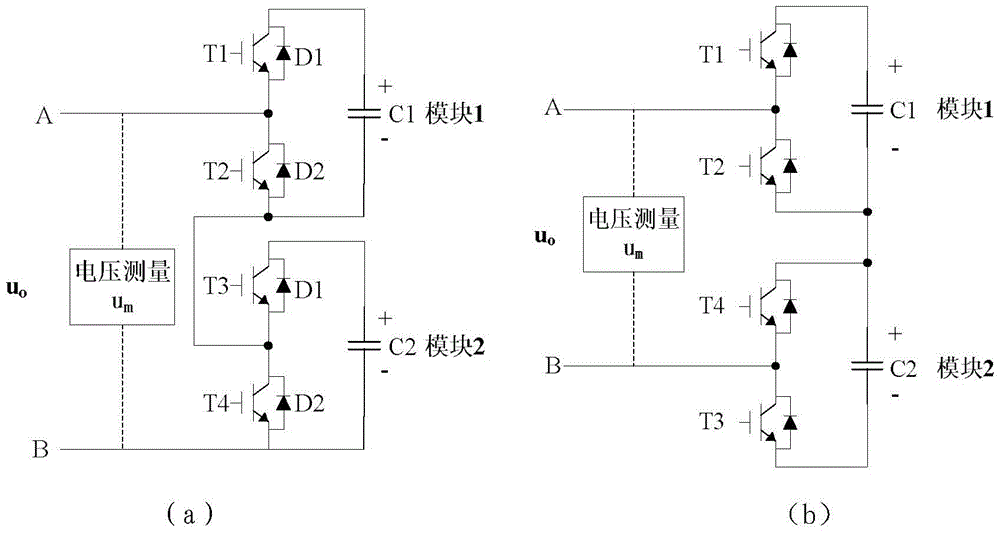

[0046] The method provided by the invention is applicable to single-capacitor or double-capacitor modules whose output voltages of all modules in the MMC are greater than or equal to 0.

[0047] Such as figure 2 The dual-capacitor module shown in (b) can be regarded as a simplified or equivalent topology of various dual-capacitor modules when the module is working normally, and it is the same as figure 2 The series topology of two half-bridge single-capacitor modules shown in (a) works on the same principle, so the figure 2 The dual-capacitor module shown in (b) is taken as an example.

[0048] The proposed method of voltage measurement and fault location of MMC module based on condition monitoring selects the voltage collection point in such as figure 2 The output port of the dual capacitor module shown in (b), the algorithm is implemented in this MMC system.

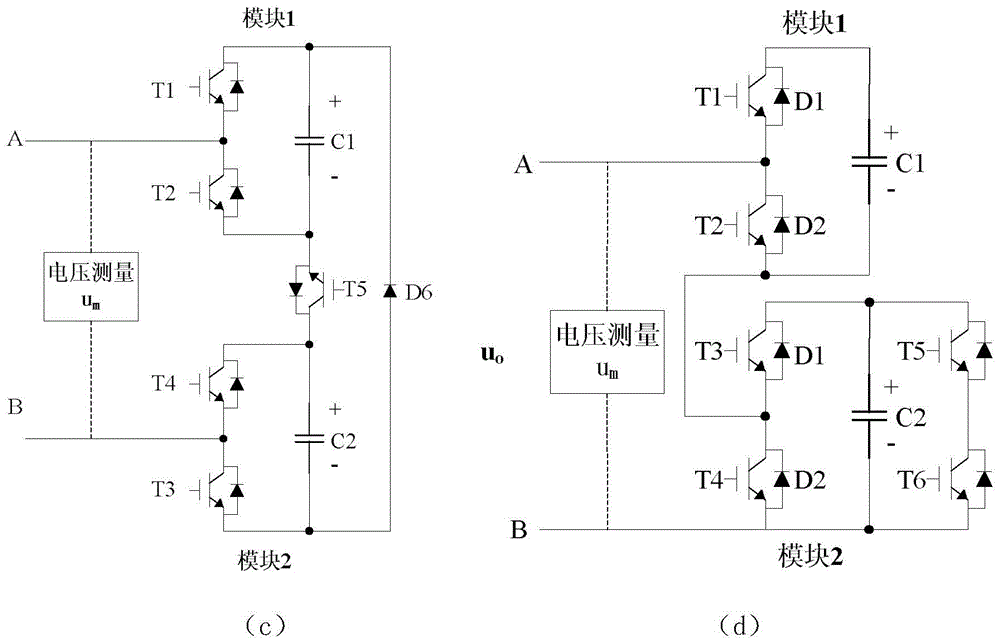

[0049] Such as image 3 As shown, the MMC module voltage measurement method based on state monitoring includ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com