A zinc alloy zipper

A zinc alloy and zipper technology, applied in the direction of sliding fastener components, applications, fasteners, etc., can solve problems that are difficult to eliminate, dull surface, hardening, etc., to prevent thermal deterioration, good tensile performance, and high tensile performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

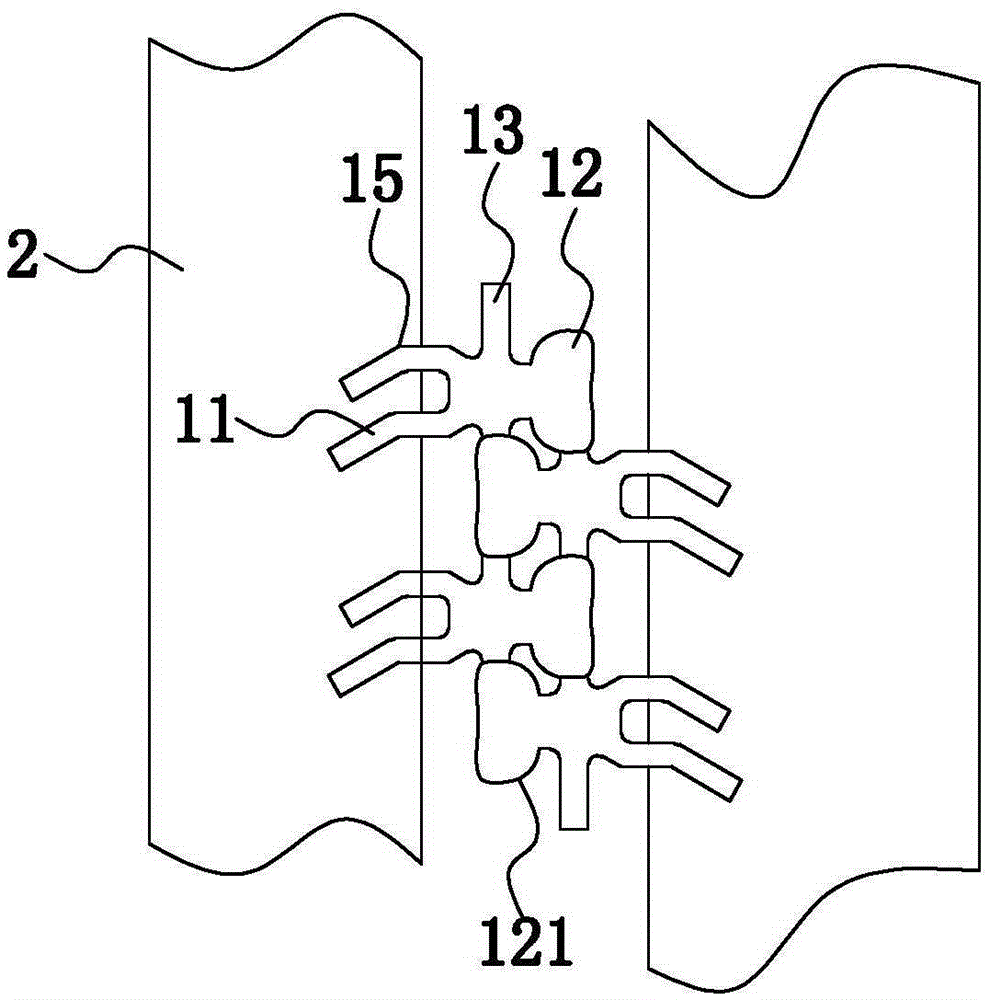

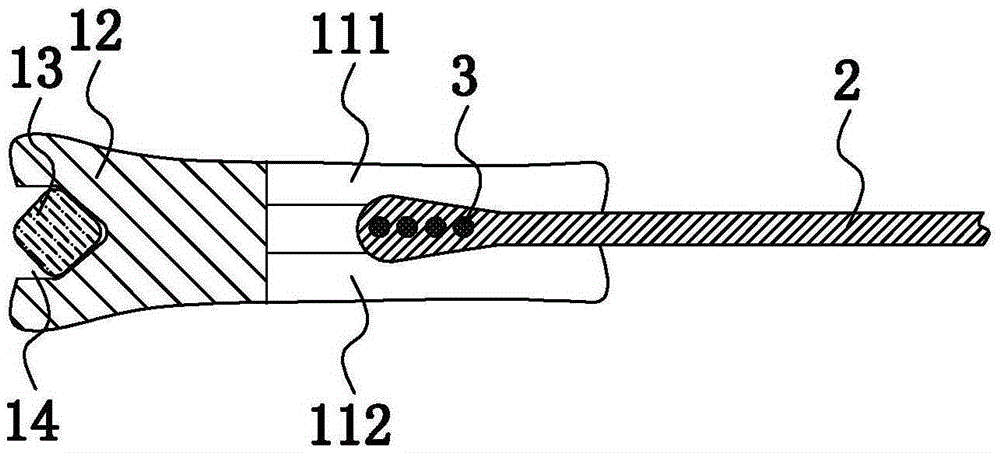

[0014] figure 1 , figure 2 As shown, a zinc alloy zipper includes a chain element, a slider, and two chain straps 2. A row of chain teeth is respectively embedded in the opposite sides of the two chain straps 2, and the two rows of chain teeth are mutually misaligned and meshed. On the chain elements of the opposite side plates of the belt 2, each chain element includes an engaging portion 11 embedded in the chain belt and an engaging portion 12 for mutual engagement, and the engaging portion 11 includes an upper engaging portion 111 and a lower engaging portion 112, so The upper engaging portion 111 and the lower engaging portion 112 are U-shaped respectively. The left and right sides of the engaging part 12 are respectively provided with snap-in rods 13, and the side of the engaging part 12 close to the other chain belt 2 is prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com