Raw material smashing device for single crystal furnace

A raw material pulverization, single crystal furnace technology, applied in post-processing devices, crystal growth, grain processing and other directions, can solve problems such as the inability to apply single crystal silicon production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

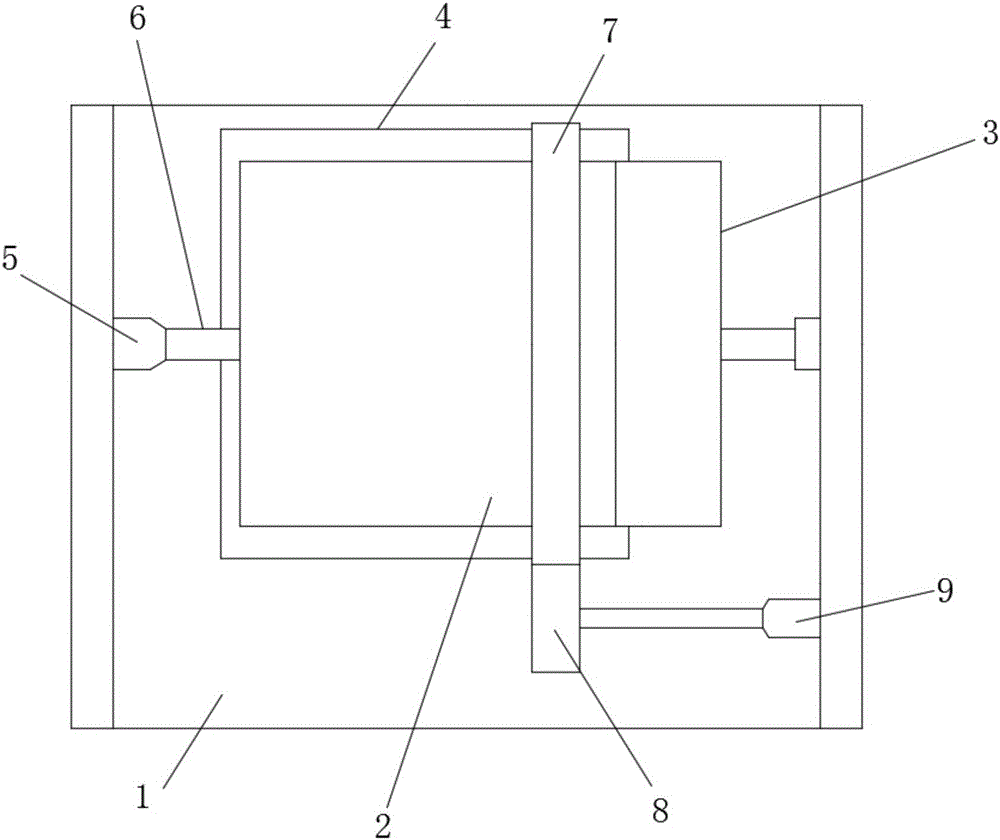

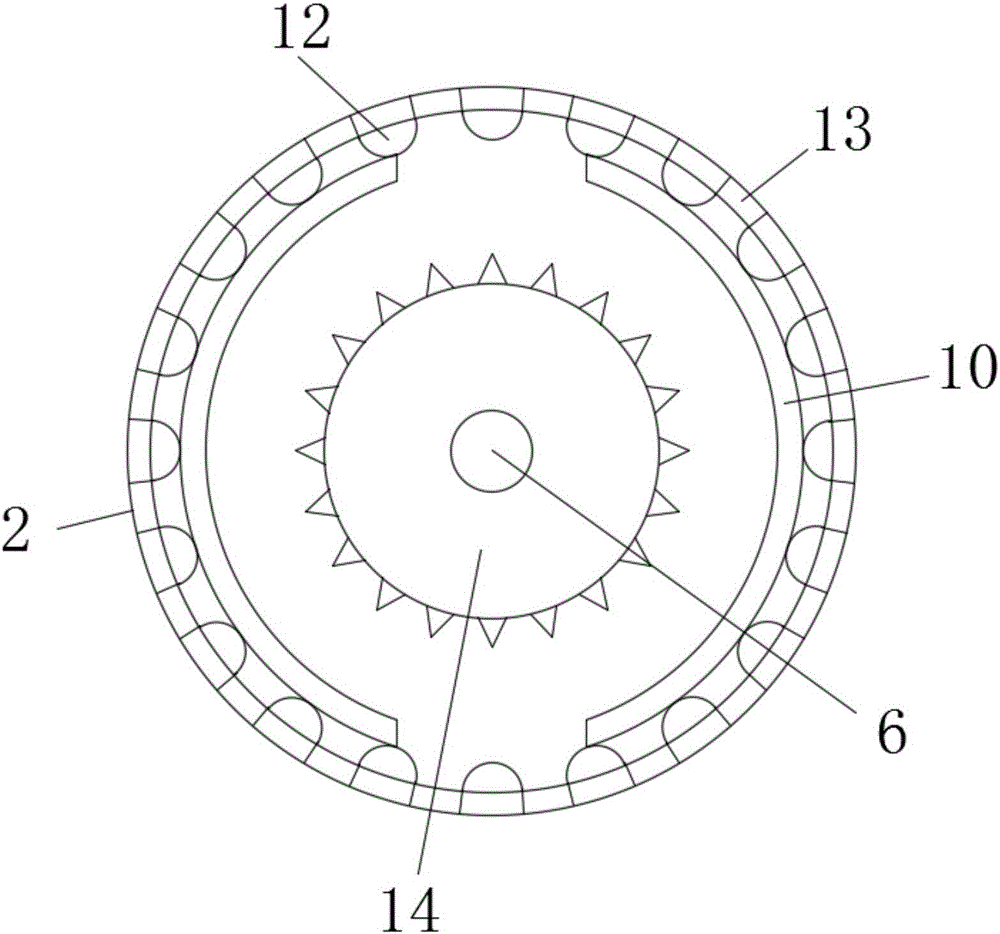

[0018] Such as figure 1 and figure 2 The shown raw material crushing device for single crystal furnaces includes a "U"-shaped support 1, a rotating shaft 6, a crushing drum 2, a crushing wheel 14 and a storage box 4, and the rotating shaft 6 is horizontally movably connected to the Between the two side walls of the U"-shaped bracket 1, one end of the rotating shaft 6 is movably connected on the side wall of the "U"-shaped bracket 1 through a bearing, and the other end of the rotating shaft 6 is connected to the first motor 5 connected, the first motor 5 is installed on the other side wall of the "U"-shaped bracket 1, and the crushing drum 2 is arranged between the two side walls of the U"-shaped bracket 1, and the crushing drum The left end of 2 is movably connected with a support cylinder 3, the rotating shaft 6 is movably connected with the support cylinder 3 through the crushing drum 2, the crushing drum 2 is connected with the rotating mechanism, and the crushing wheel 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com