Machining method for hollow discontinuous deep hole with inclined workblank face

A processing method and blank surface technology, which is applied in the field of deep hole processing in hollow spaces, can solve problems such as the lack of versatility of the processing method, limited clamping, and inability to guarantee the positional accuracy requirements, so as to reduce the probability of breaking the drill bit, The effect of eliminating position deviation and eliminating adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

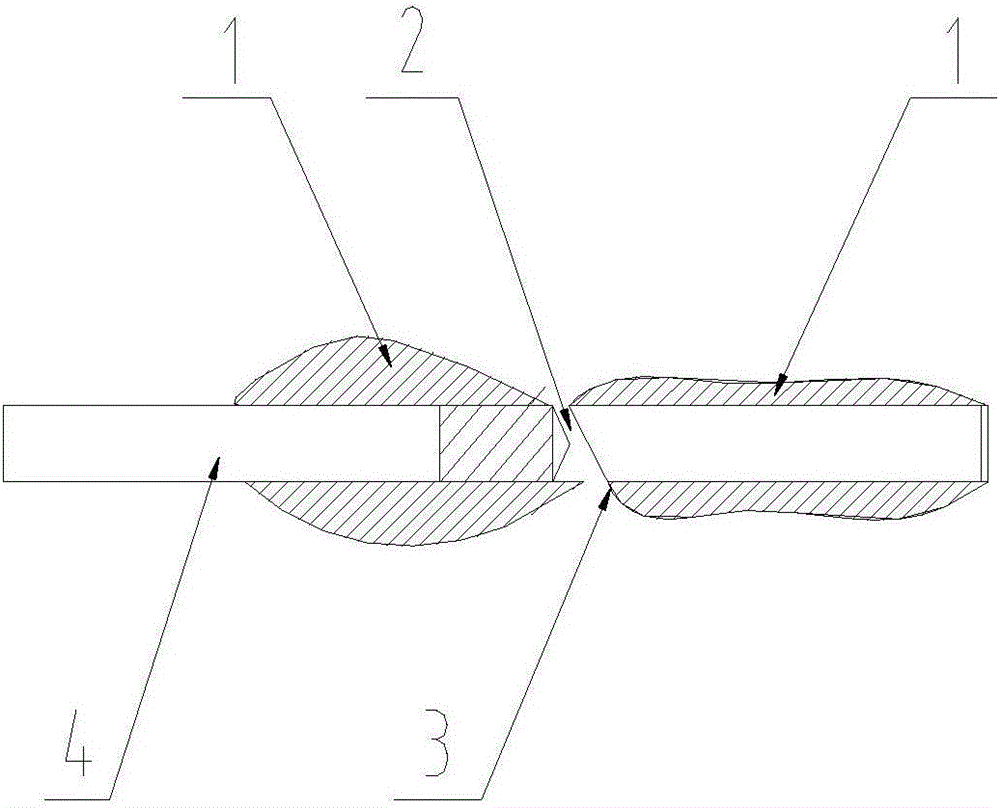

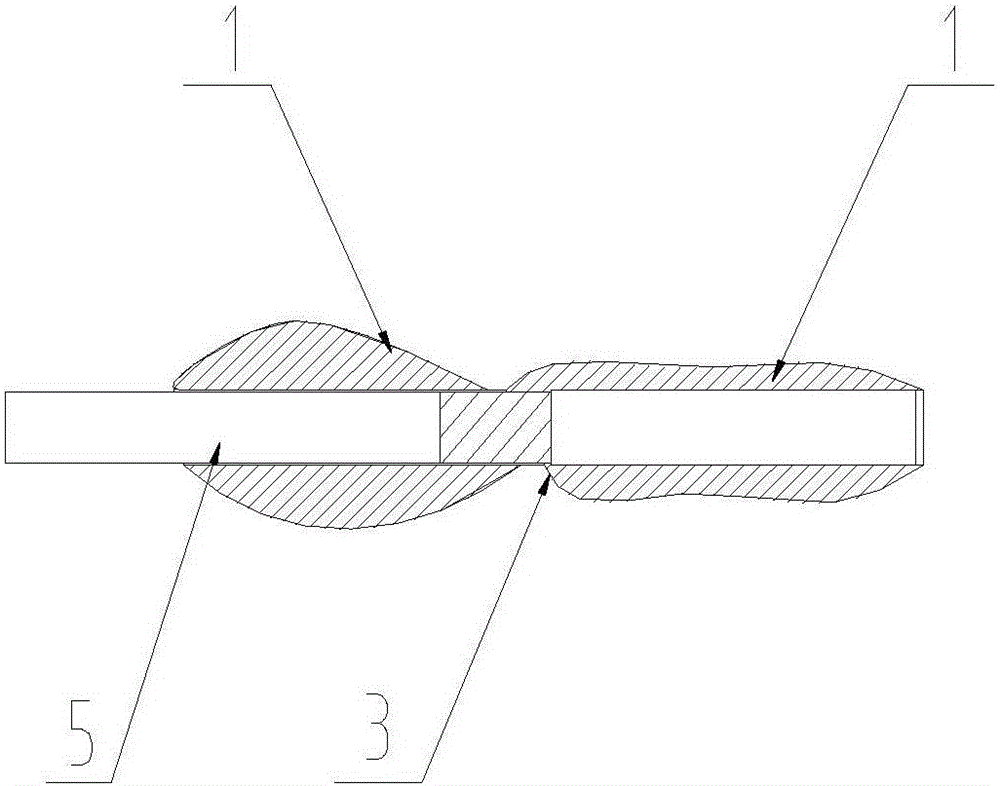

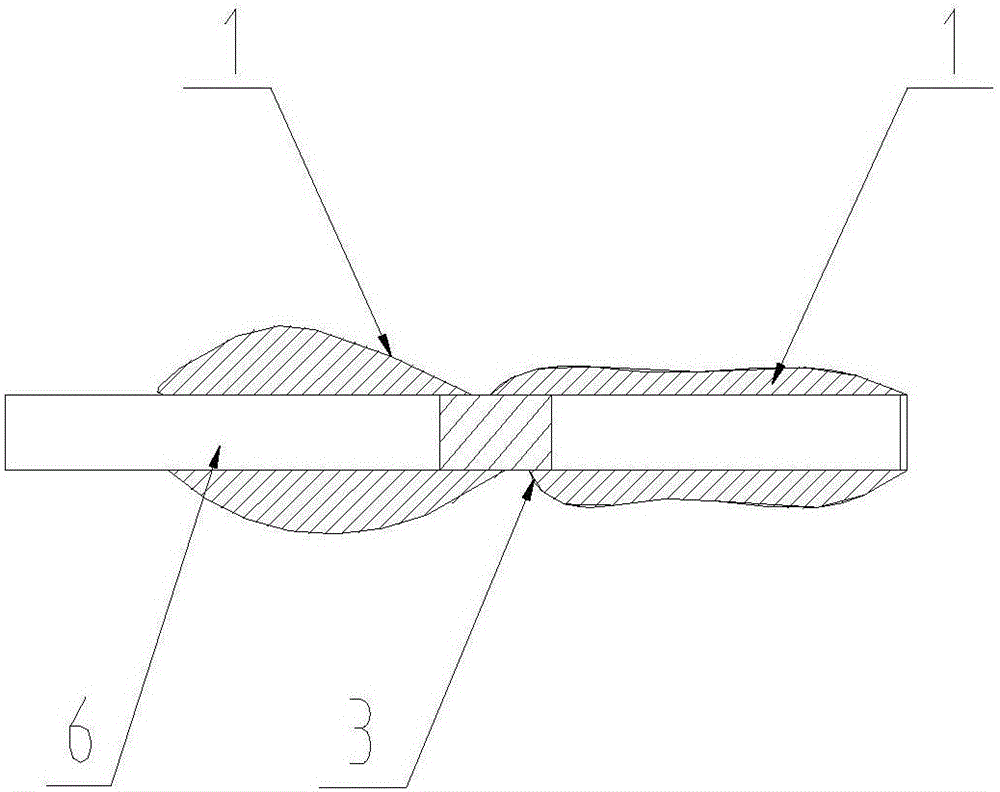

[0033] see Figure 1 to Figure 4 , is a preferred embodiment of the processing method of the hollow interrupted deep hole with an inclined blank surface. In this embodiment, the processing method is used to process the hollow interrupted deep hole of the bearing shell. The hollow interrupted deep hole includes two processing hole sections, and a hollow section between the two processing hole sections. The opposite orifice end faces of the two processing hole sections are oblique blank surfaces, and the desired machining diameter of the two processing hole sections is D21, the method is carried out in the following steps:

[0034] Step 1, select the outer end of the shorter processed hole segment among the two processed hole segments as the processing entry end of the hollow spaced deep hole, and use an end mill to mill and flatten the hole end face of the entry end so that the hole end face is vertical Interrupt the deep hole in the hollow;

[0035] Step 2, see figure 1 , c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com