Process and equipment for producing ceramsite aerated building blocks

A technology of aerated blocks and production equipment, which is applied in the direction of manufacturing tools, clay preparation devices, supply devices, etc., and can solve the problems of high cost, many workers, and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

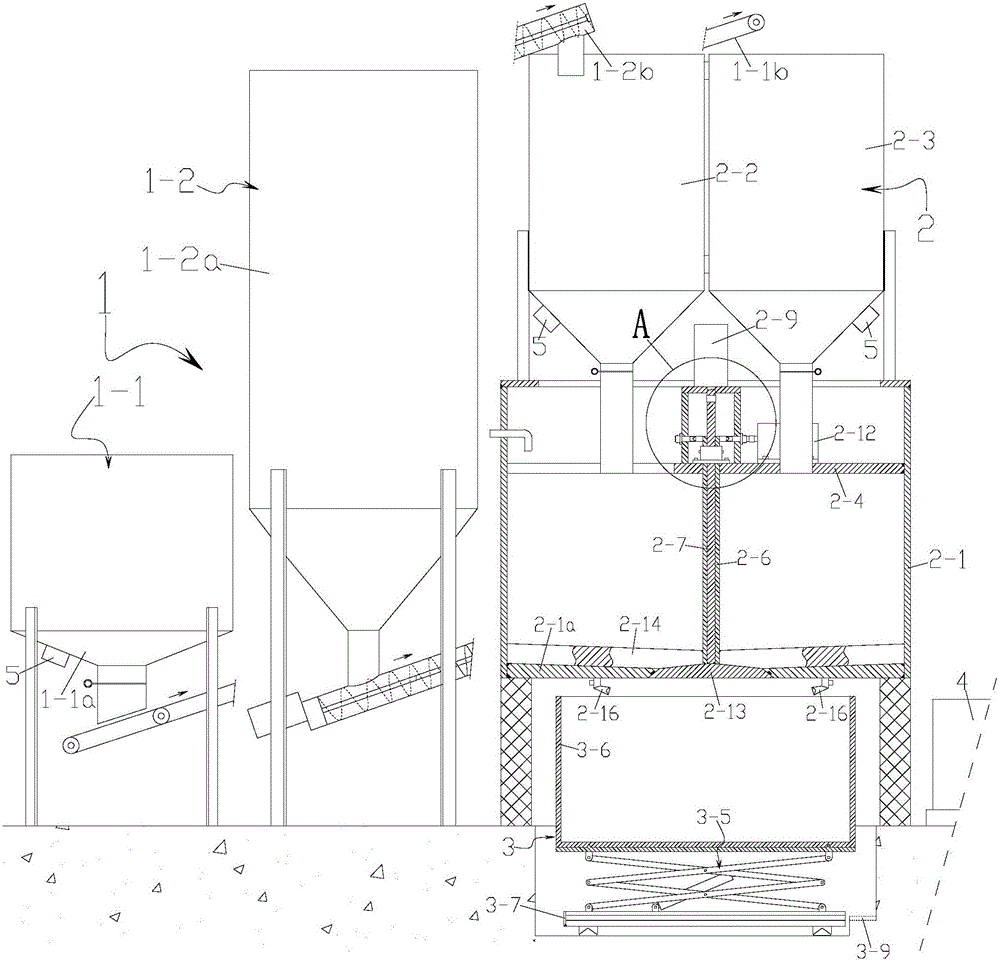

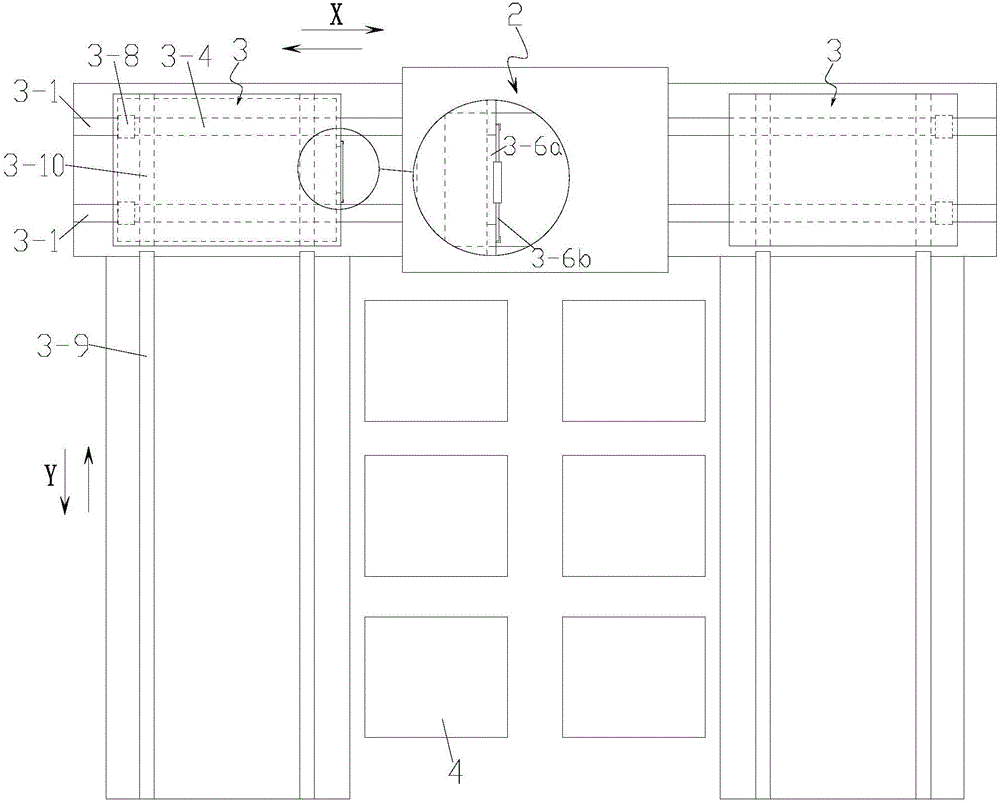

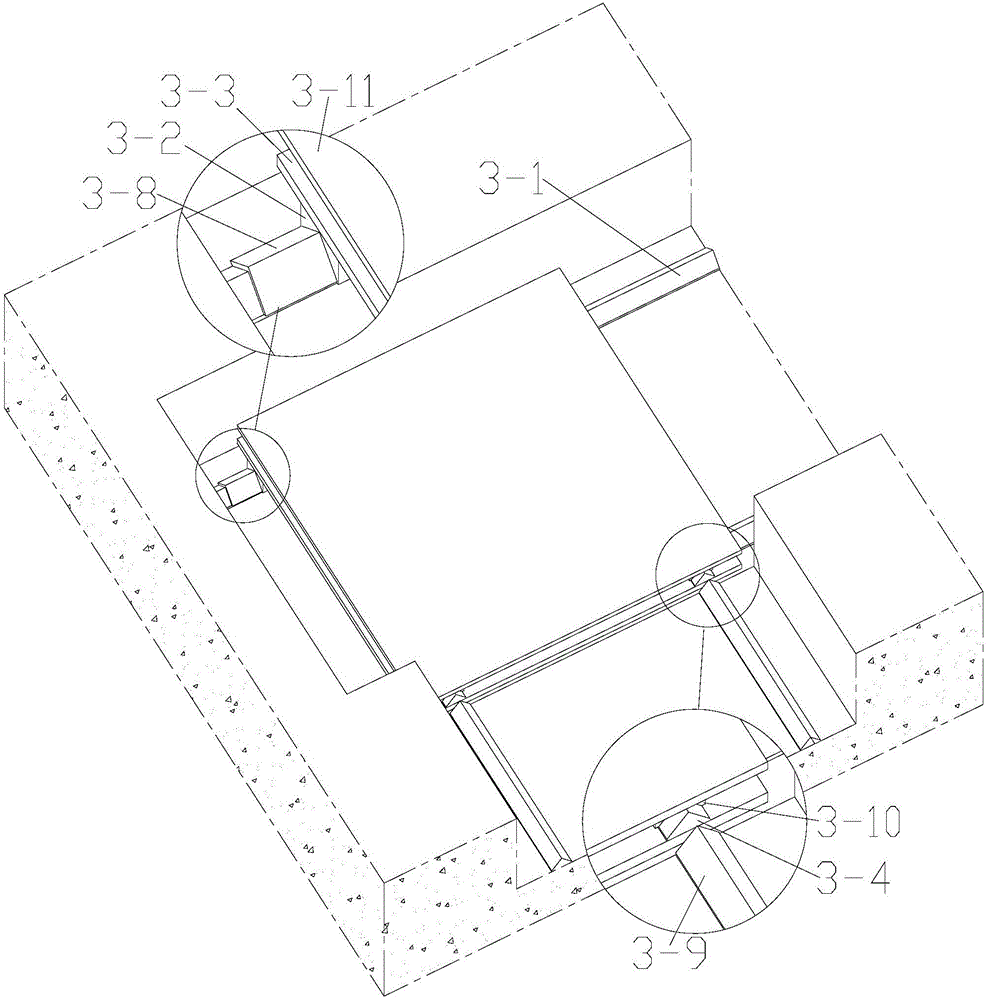

[0035] The present invention will be further described below in conjunction with accompanying drawing:

[0036] Refer to attached figure 1 , 2 , 3, 4, 5, 6, 7, 8, 9, 10, 14: This ceramsite aerated block production process includes the following steps:

[0037] A. Raw material transportation: put the ceramsite raw material into the hopper 1-1a of the ceramsite conveying mechanism 1-1, put the bulk cement into the cement tank 1-2a of the cement conveying mechanism 1-2, and pass the ceramsite The conveyor belt 1-1b on the conveying mechanism 1-1 is conveyed to the first hopper 2-2, and the cement is conveyed to the second hopper 2-3 by the screw propeller 1-2b in the cement conveying mechanism 1-2;

[0038] B. Stirring of raw materials: The ceramsite and cement mixed together drive the worm 2-11 through the servo motor 2-12, and then drive the worm wheel 2-10 to rotate through the worm 2-11, and the worm wheel 2-10 drives the shaft 2-6 together Rotate, the stirring plate 2-14 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com