Automatic packaging device for O-shaped rings

An automatic packaging, O-ring technology, applied in packaging, packaging protection, transportation and packaging, etc., can solve the problems of low packaging efficiency, inability to meet production needs, time-consuming and labor-intensive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

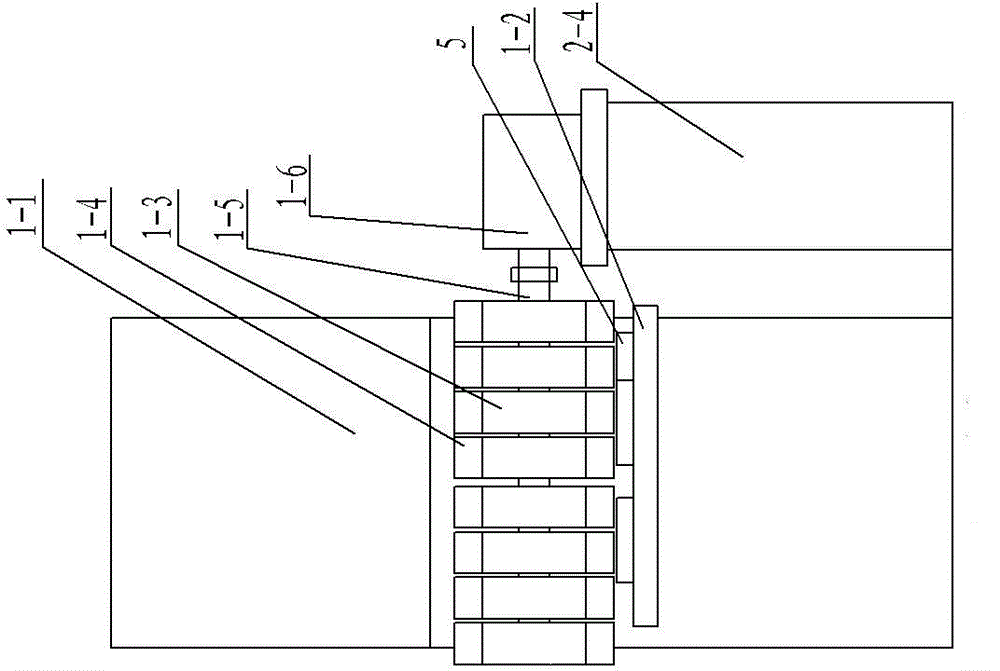

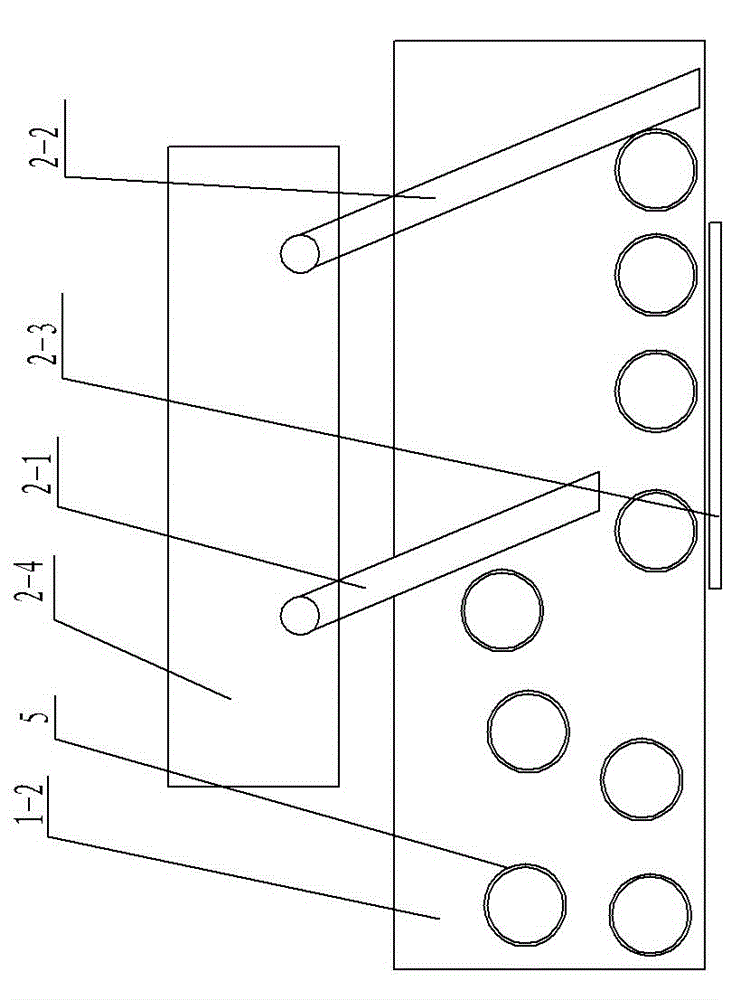

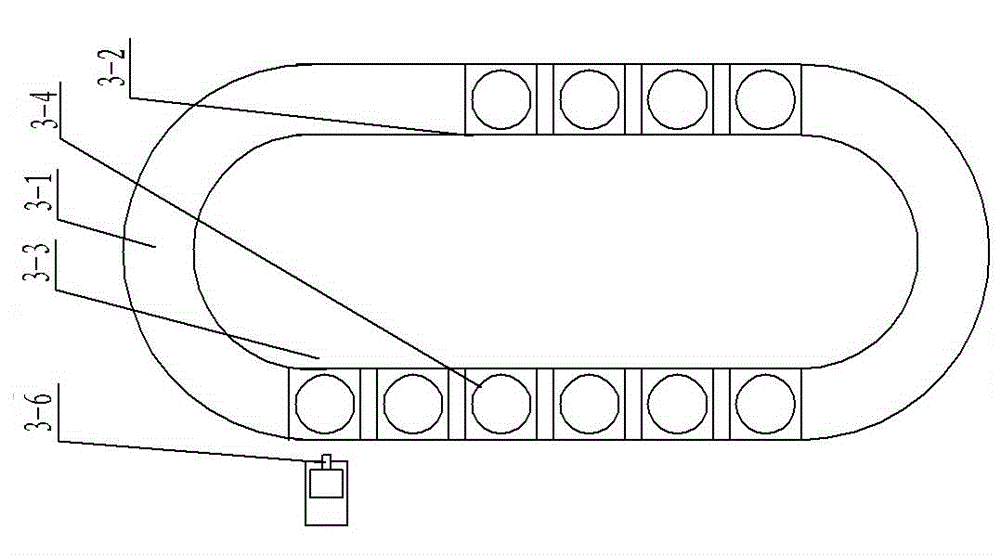

[0025] See figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 As shown, an O-ring automatic packaging device includes a material distributing device 1 , an arrangement and blanking device 2 , a material receiving device 3 , and an automatic packaging device 4 .

[0026] The material distribution device 1 includes a bucket elevator 1-1 and a conveyor belt 1-2, a roller 1-3 is installed on the upper end of the conveyor belt 1-2, an annular brush 1-4 is installed on the roller 1-3, and the rotating shaft of the roller 1-3 1-5 is connected to the drive motor 1-6, the direction of the linear velocity at the bottom of the roller 1-3 is opposite to the conveying direction of the conveyor belt 1-2, and the distance between the ring brush 1-4 and the conveyor belt 1-2 is greater than an O-shaped The thickness of the ring 5 is less than the thickness of the two O-rings 5; the O-ring 5 falls from the bucket elevator 1-1 and falls on the conveyor belt 1-2, and the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com