Counting finishing machine for plastic gloves

A technology of plastic gloves and finishing machines, which is applied in the direction of conveyors, conveyor objects, packaging, etc., can solve the problems of not being neatly stacked, and achieve the effect of convenient packaging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The following is a further detailed description of a plastic glove point sorting machine according to the present invention through specific examples.

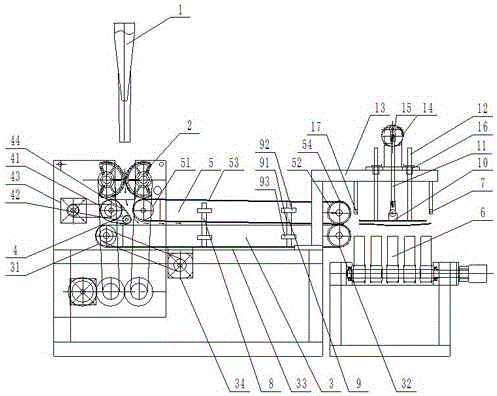

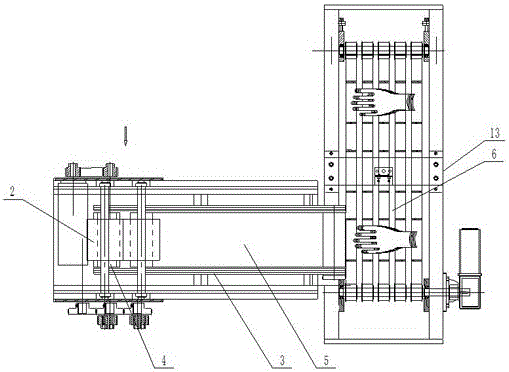

[0015] Such as figure 1 , figure 2 As shown, the plastic glove counting machine includes a pair of cams 2 arranged directly below the hand mold 1. A horizontal conveyor belt 3 is provided below the cam 2, and a feeding belt 3 is provided above the conveyor belt 3. Belt 4 and pressing belt 5, the feeding belt 4 is arranged on the feeding front side of the pressing belt 5, the feeding belt 4 is gradually inclined downward along the conveying direction, and the pressing belt 5 is gradually inclined downward along the conveying direction. The rear end of the belt 5 is attached to the rear end of the conveyor belt 3, a finishing belt 6 is arranged on the rear side of the conveyor belt 3, a flattening device is arranged above the finishing belt 6, and a counting photoelectric switch 7 is arranged on the side of the finishin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com