Conveying platform with lifting structure

A lifting structure and platform technology, applied in the direction of transportation, packaging, loading/unloading, etc., can solve the problems of laborious loading and unloading of goods, and achieve the effects of improving efficiency, convenient movement, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

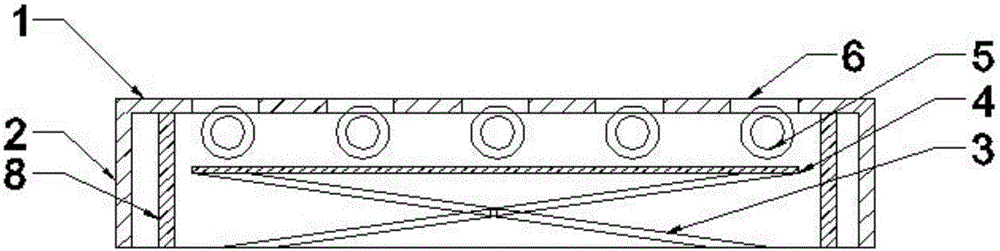

[0026] A platform with a lifting structure on the top surface, the platform includes a plane 1, a middle frame 2, a lifting system 3, a lifting surface 4, and a rolling member 5. The plane 1 and the middle frame 2 form a bottomless cubic structure with space inside, The lifting system 3 is fixed inside the cube, and the lifting system 3 is connected to the lifting surface 4, and the lifting surface 4 is provided with a rolling element 5, and the rolling element 5 is arranged between the lifting surface 4 and the plane 1 (ie, the top surface). between; the plane 1 (ie, the top surface) is provided with holes or grooves 6 through which the rolling elements 5 can pass. When the rolling member 5 is a roller, there is a long groove corresponding to the roller on the plane 1, and the roller can rise above the plane 1 through the long groove, so that the sliding friction between the goods and the plane becomes rolling friction. When the rolling member 5 is a plurality of universal b...

Embodiment 2

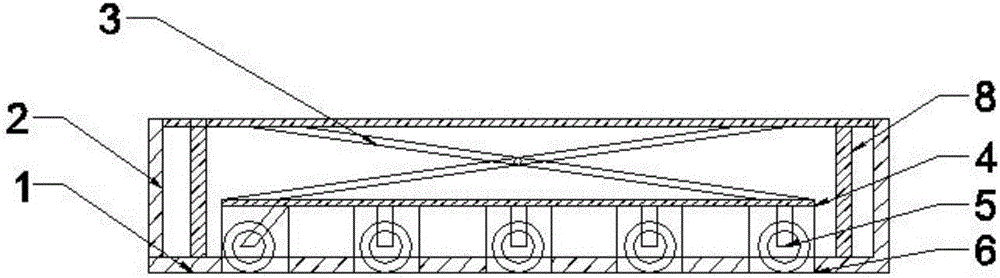

[0028] as attached figure 2 As shown, a platform with a lifting structure on the bottom surface includes two planes 1, a middle frame 2, a lifting system 3, a lifting surface 4, and rolling parts 5. The plane 1 and the middle frame 2 form a cubic structure with space inside. , the lifting system 3 is fixed inside the cube, and the lifting system 3 is connected to the lifting surface 4, the lifting surface 4 is provided with a rolling element 5, and the rolling element 5 is arranged between the lifting surface 4 and the bottom plane; The plane 1 is provided with holes capable of passing the rolling elements 5 . The rolling member 5 is a wheel, and the wheel includes universal wheels, and two universal wheels are located on the same side of the pallet, and the universal wheels are provided with a brake mechanism. The lifting system 3 is a screw lifting system. One side of the middle frame 2 is also provided with a dragging piece 7, and the dragging piece 7 is located on the s...

Embodiment 3

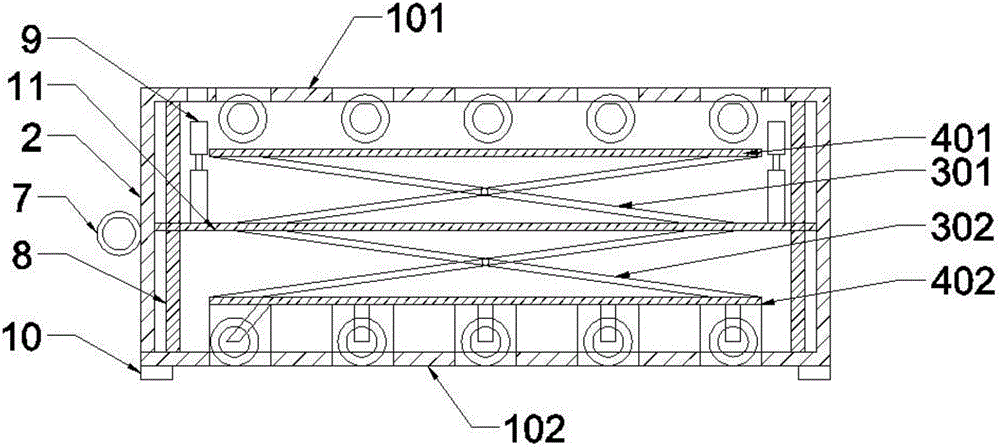

[0030] Platform with lifting mechanism on both sides, as attached image 3 As shown, the table top includes two planes (i.e., upper plane and lower plane), middle frame 2, lifting system 3, lifting surface 4, and rolling member 5. The plane and middle frame 2 form a cubic structure with space inside, so The lifting system 3 is fixed inside the cube, and the lifting system 3 is connected to the lifting surface 4, and the lifting surface 4 is provided with a rolling element 5, and the rolling element 5 is arranged between the lifting surface 4 and the plane 1; A hole that can pass through the rolling element 5 is arranged on the plane.

[0031] The lifting surface 4 includes an upper lifting surface 401 and a lower lifting surface 402, the lifting system 3 includes an upper lifting system 301 and a lower lifting system 302, the upper lifting surface 401 is connected to the upper lifting system 301, and the lower lifting system 3 The surface 402 is connected to the lower lifting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com