Lifting pulley capable of being quickly clamped or released by rotary lifting spine lock, synchronously opened-closed C-shaped spring and five wheels

A technology of hoisting tackle and hoisting trolley seat, which is applied in the field of hoisting trolleys, which can solve problems such as unsafety, inconvenient use, and accidents, and achieve the effect of easy installation and strong interchangeability of spare parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

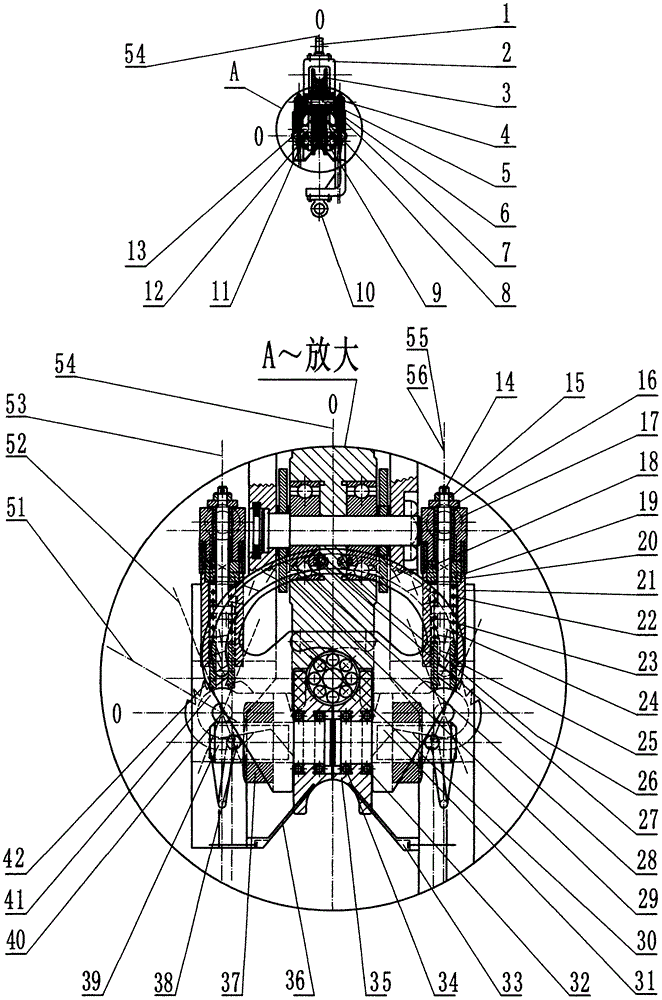

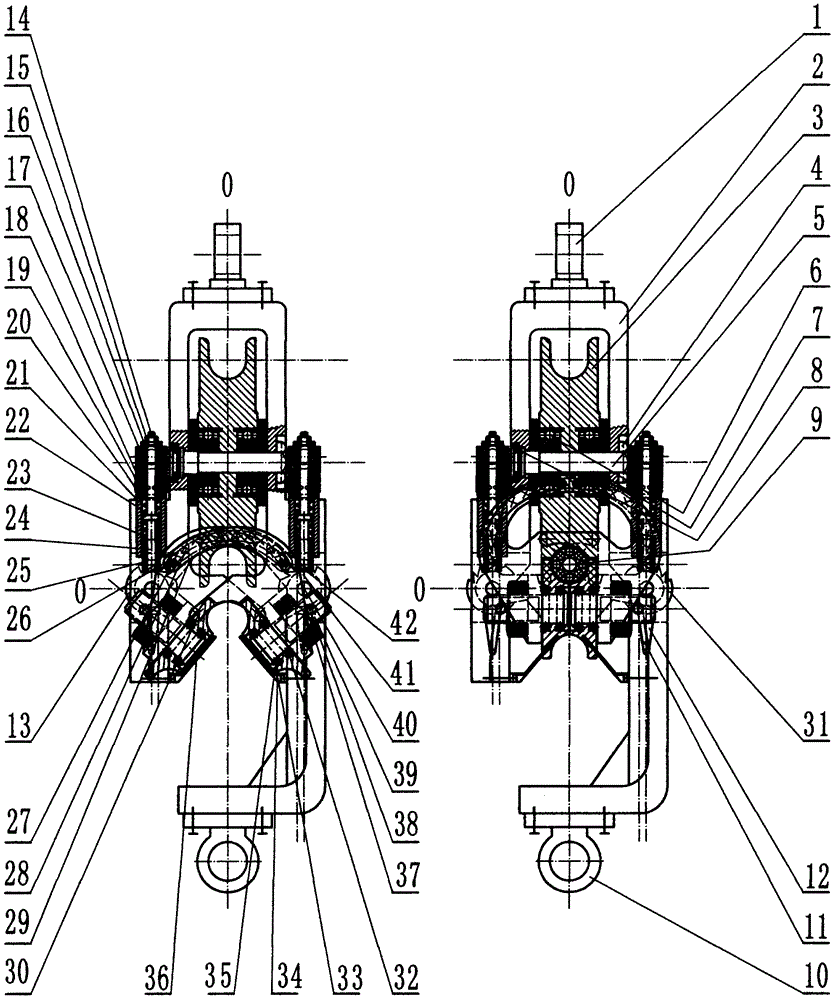

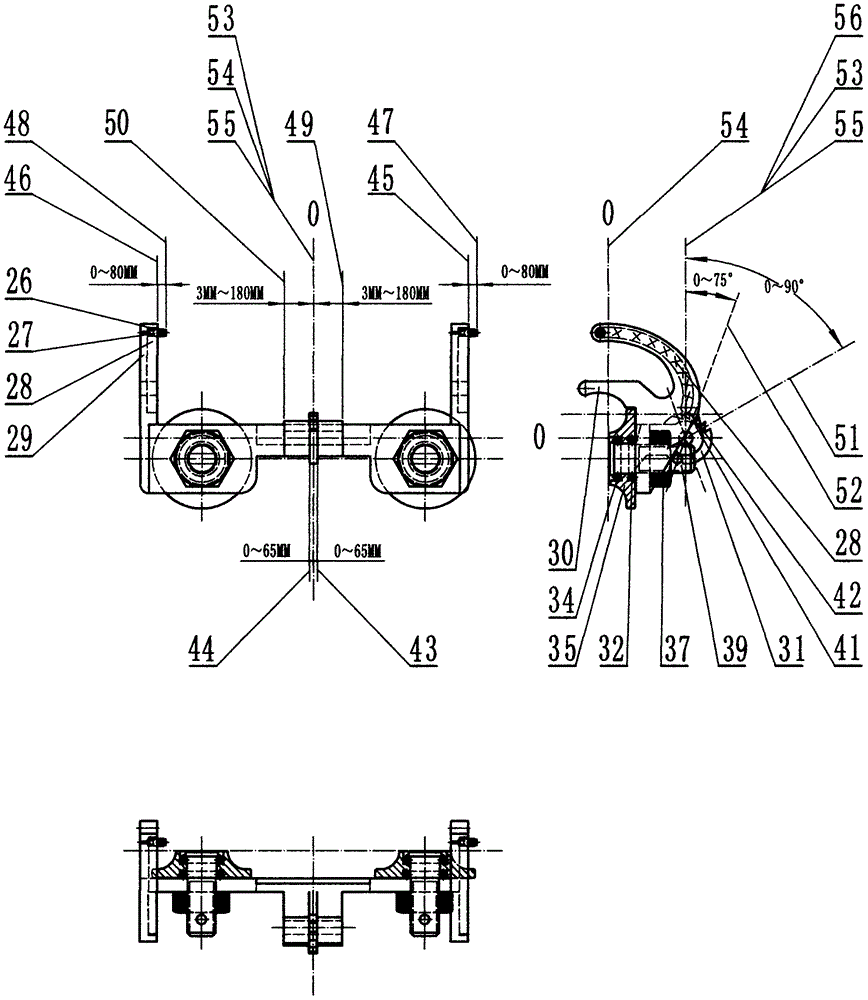

[0013] The technical scheme adopted by the present invention is: composed of a rotating lifting ratchet lock assembly, a hoisting block assembly, a hoisting pulley assembly, and a synchronous opening and closing clamping seat assembly;

[0014] See 1. figure 2 .The rotary lifting ratchet lock assembly is composed of a shaft pin (14), a square lifting ratchet rod fastening screw cap (15), a flat gasket (16), a slope rotary lifting handle (17), and a slope rotary lifting seat fastening screw (18), fastening ear (19), slope rotation lifting seat (20), ratchet lock seat (21), upper spring (22), lower spring (23), square lifting ratchet rod (24), inner square hole elastic Stop sleeve (25) is formed. The ratchet lock seat (21) and the fastening ear (19) are integrally formed by casting or mechanical processing, and are fastened in the holes on the left and right sides of the suspension block (2) with screws, and the inner square hole elastic stop sleeve (25 ) is fitted into the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com