Large-diameter hot glass rod on-line automatic cutting device

A hot glass, large diameter technology, applied in glass cutting devices, glass manufacturing equipment, manufacturing tools, etc., can solve the problems of large error in the length and length of glass rods, uneven cross-section, easy scalding, labor intensity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

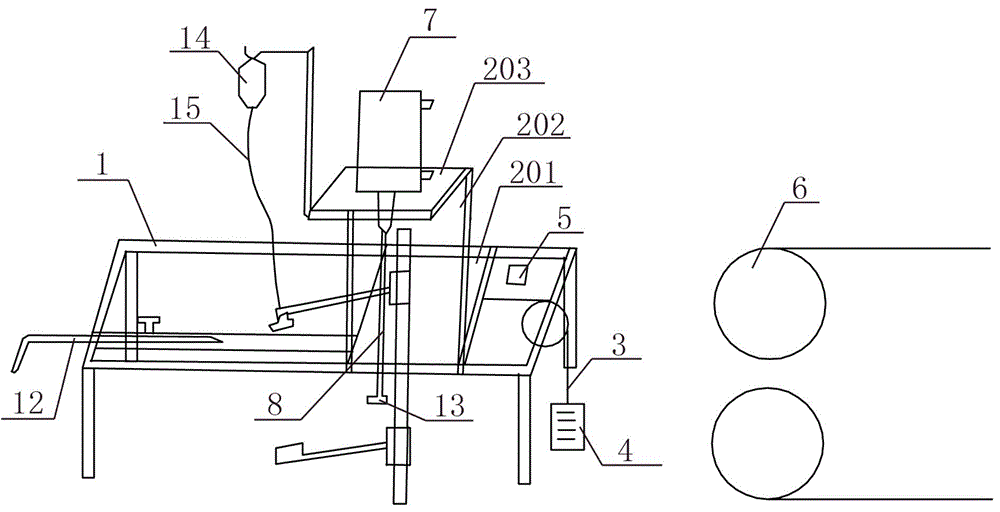

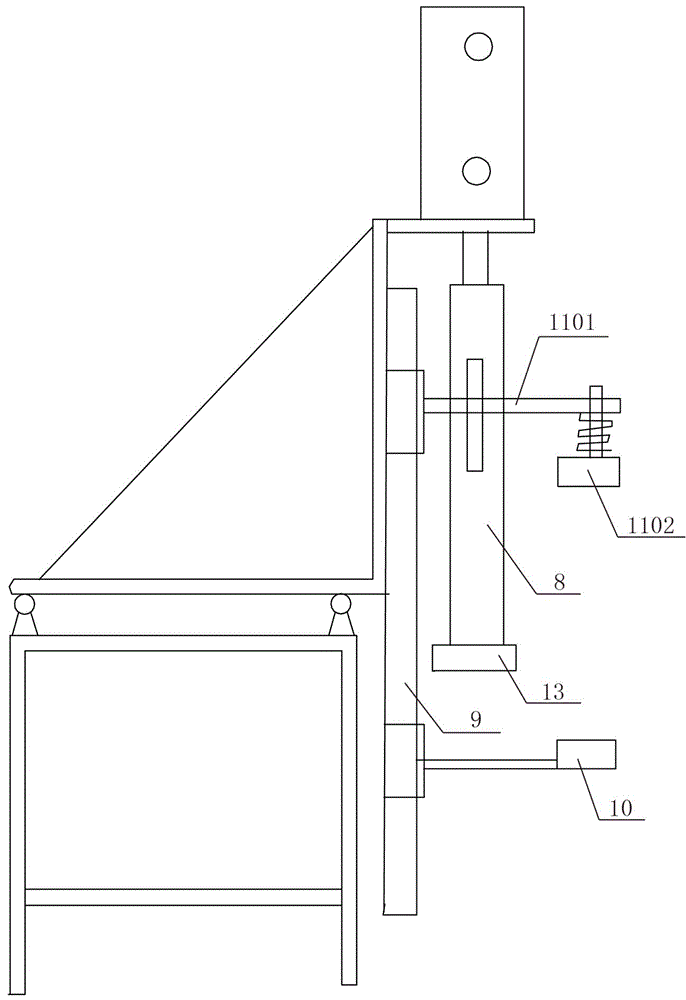

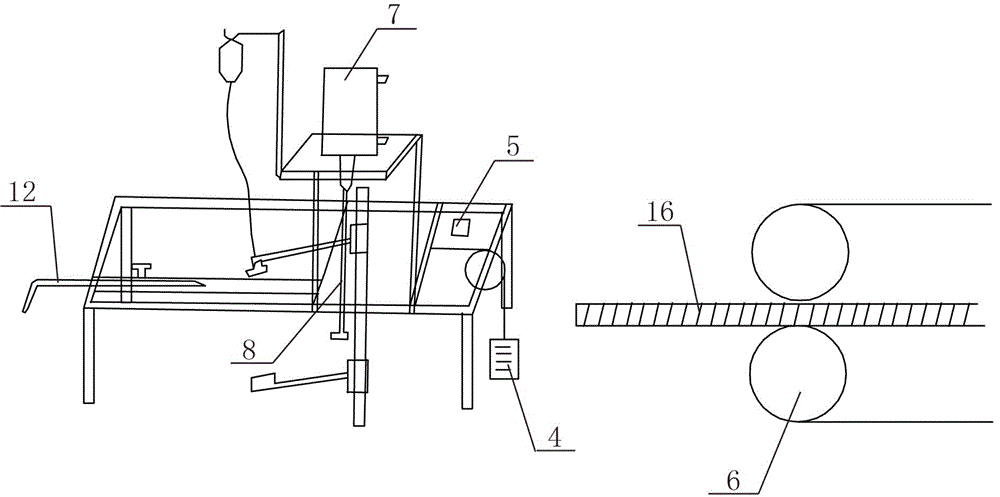

[0016] Such as figure 1 Shown is a large-diameter hot glass rod online automatic cutting device, which includes a support 1, a knife rest mobile platform 2 is arranged on the support 1, the knife rest mobile platform 2 is connected with the support through a knife rest moving track, and the knife rest mobile platform 2 is a The side is connected with the heavy hammer 4 through the rope 3, and a proximity switch 5 is provided on the support 1 and next to the tool holder mobile platform 2, and a tractor 6 is provided on one side of the support 1;

[0017] The knife rest mobile platform comprises the first horizontal platform 201 that is connected with the knife rest moving track, the vertical platform 202 that is located on the horizontal platform and the second horizontal platform 203 that is connected with the vertical platform 202 top, and the second horizontal platform 203 is provided with Cylinder 7 is arranged, and cylinder 7 is connected with the upper end of connecting r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com