Water pipe maintenance cutoff tool

A technology for water pipes and tools, which is applied in the field of water pipe maintenance and cutting tools, can solve the problems that affect the work of maintenance workers and have no marking function, and achieve the effects of improving practicability, accurate cutting, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

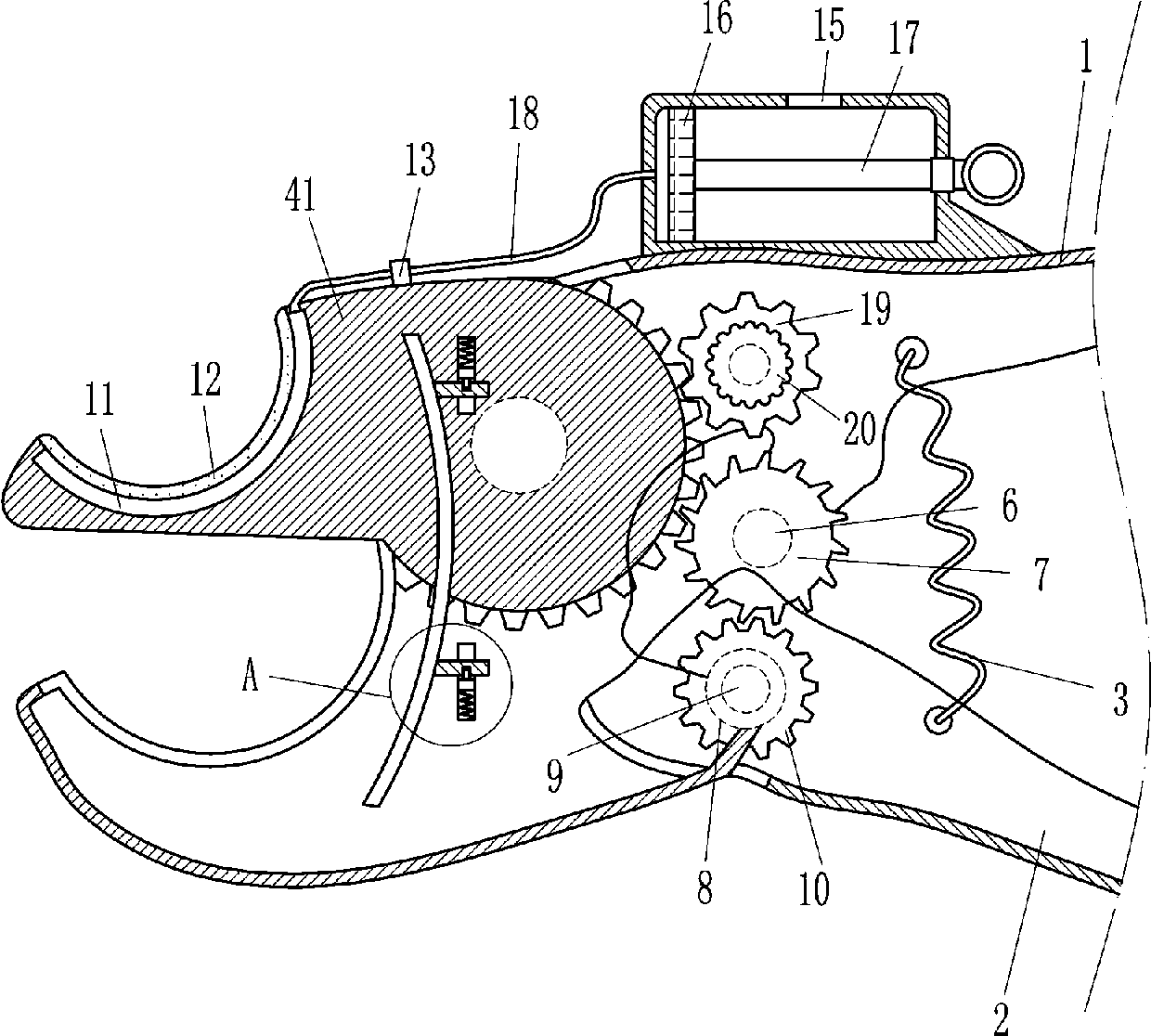

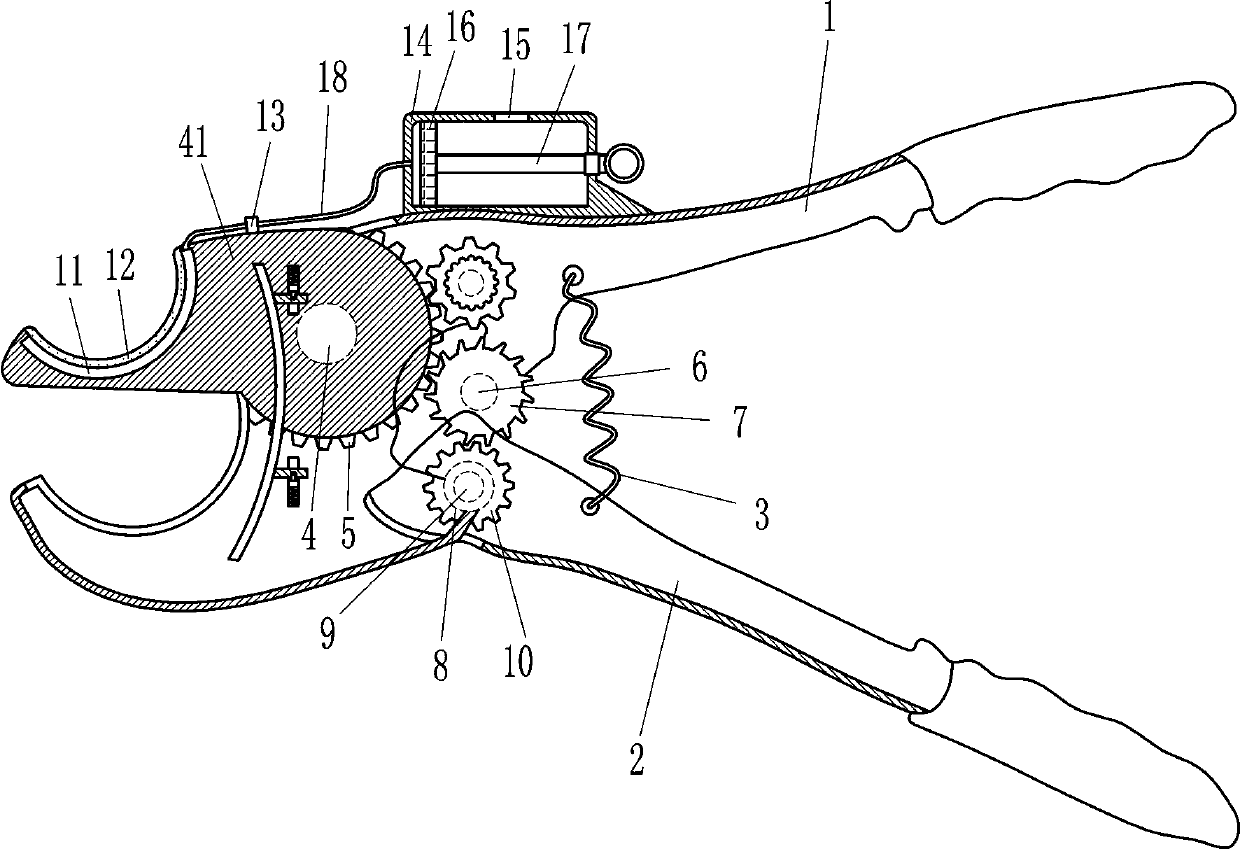

[0018] A water pipe maintenance cutting tool, such as figure 1 , 2 As shown, it includes an upper arm 1, a lower arm 2, a first spring 3, a cut-off part and a labeling part. The first spring 3 is connected between them, the upper arm 1 and the left part of the lower arm 2 are provided with a cutting part for cutting off the water pipe by rotating, and the upper arm 1 is provided with a labeling part for marking by pushing.

[0019] Such as figure 1 , 2 As shown, the cut-off part includes a first rotating shaft 4, a blade 41, an arc rack 5, a second rotating shaft 6, a transmission gear 7, an overrunning clutch 8, a third rotating shaft 9 and a pinion 10, and the left side of the upper arm 1 The first rotating shaft 4 is rotatably connected to the top of the first rotating shaft 4, and a blade 41 is connected with a key on the first rotating shaft 4. The right side of the blade 41 is welded with an arc rack 5, and the upper arm 1 on the right side of the arc rack 5 is rotata...

Embodiment 2

[0025] Such as figure 1 , 2 As shown, on the basis of Embodiment 1, in order to use the device more labor-saving, it also includes a reset gear 19 and a runner 20, and the upper arm 1 on the right side of the arc rack 5 is rotatably connected with a reset gear 19. Gear 19 meshes with arc rack 5, and the rotating part of reset gear 19 passes upper arm 1 and is connected with running wheel 20, and reset gear 19 radius is 1 / 3rd of arc rack 5 radius.

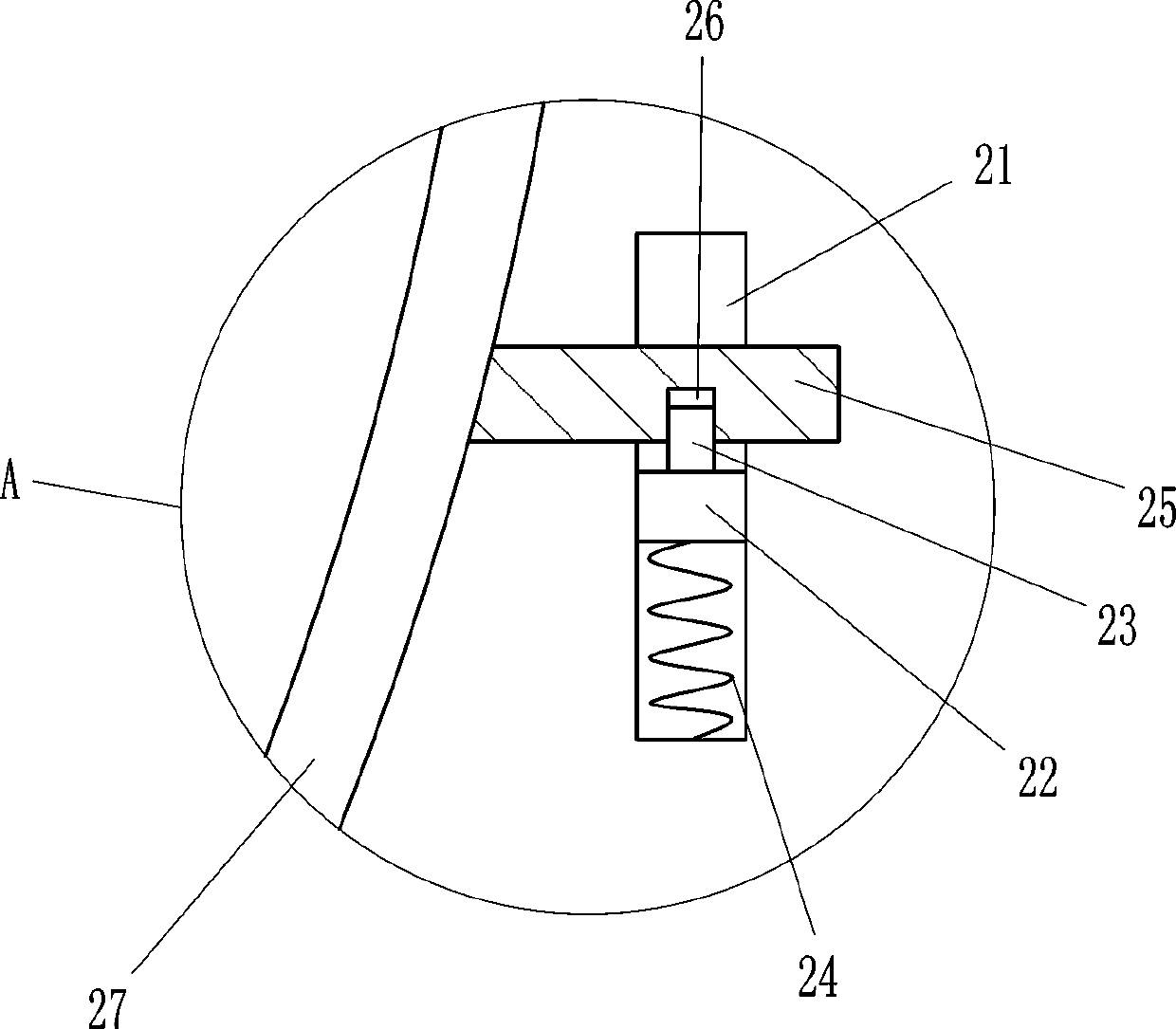

[0026] Such as figure 1 , 3 As shown, in order to prevent water from splashing to the maintenance personnel, it also includes a slider 22, a block 23, a second spring 24, a connecting rod 25 and a baffle 27, and two slide slots 21 are opened on the front and rear sides of the left part of the upper arm 1. , the two chute 21 are symmetrical up and down, the chute 21 is slidably connected with the slider 22, the inner side of the slider 22 is welded with the block 23, the second spring 24 is welded between the slider 22 and the upp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com