Coke oven flue suction adjusting device and its application method

A coke oven flue and adjusting device technology, which is applied in coking ovens, coke oven heating, combustible gas heating coke ovens, etc., can solve problems such as inability to adjust, breakage of the flap shaft, and immobility of flue flap adjustment, etc. Achieve the effects of reducing adverse effects, convenient operation and saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

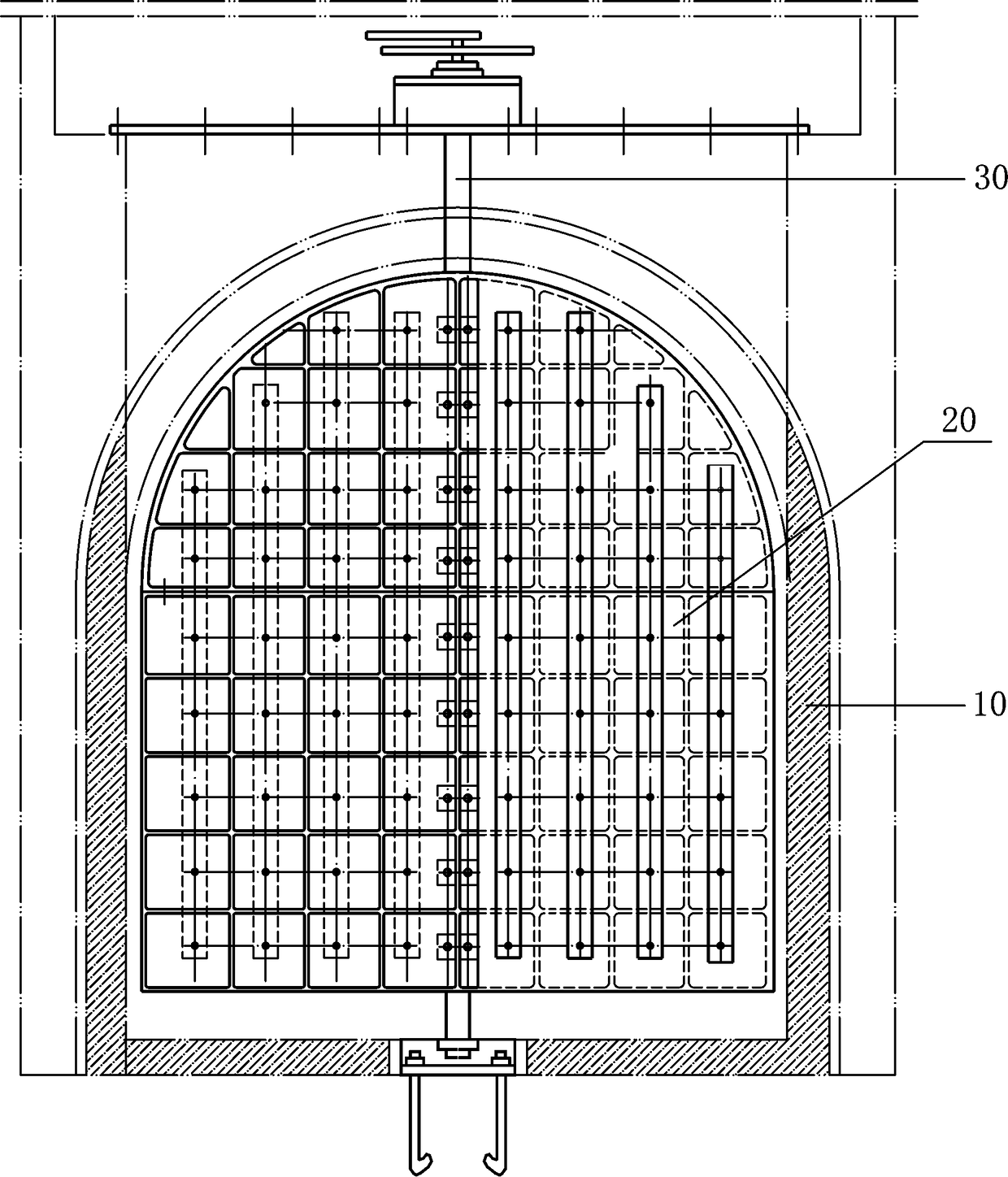

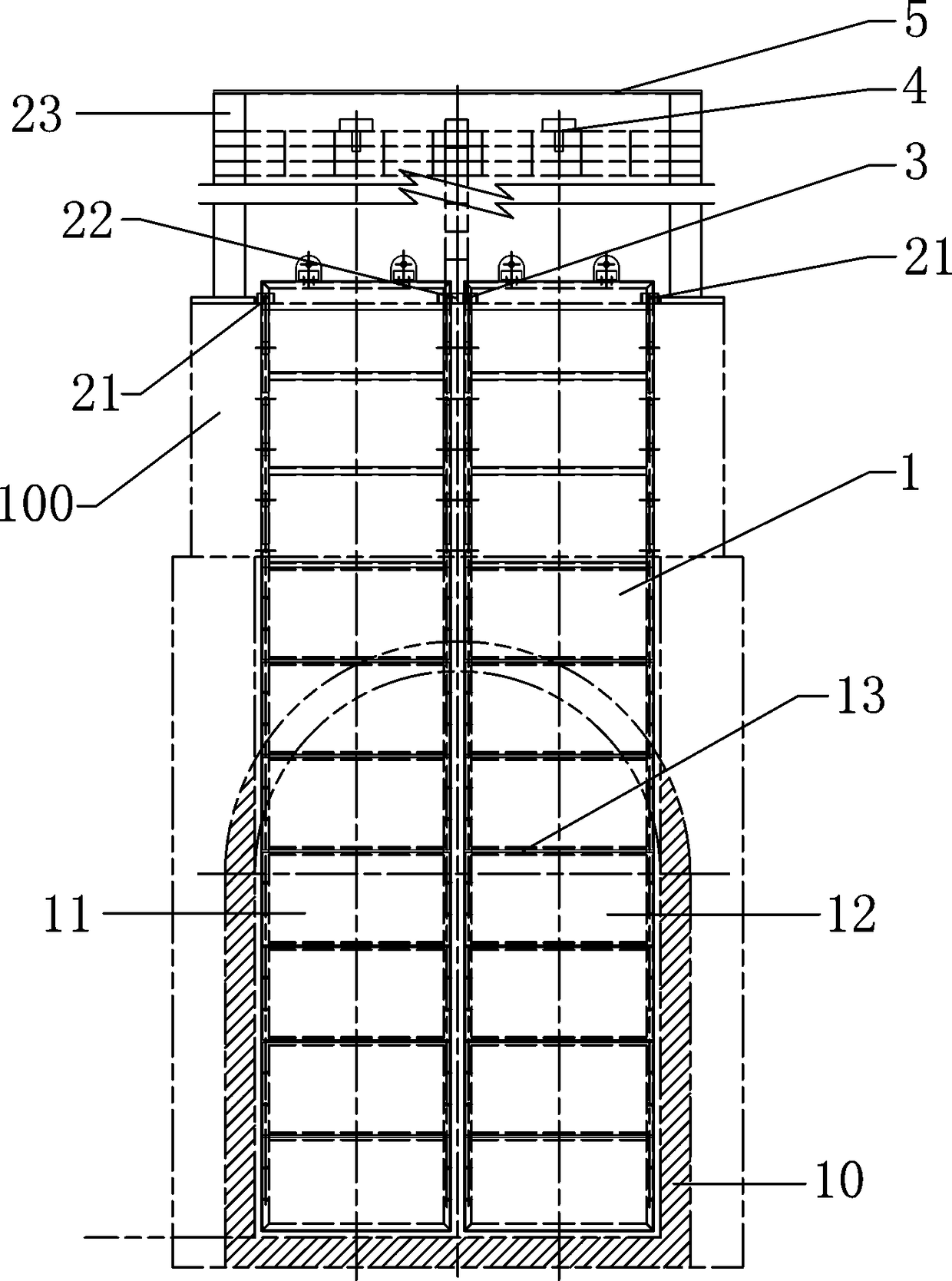

[0021] A coke oven flue suction adjustment device, comprising a flashboard 1, a side fixing frame 21, a middle fixing frame 22, a bracket 23, a fixing pin 3 and a lifting device 4, such as figure 2 As shown, the specific structure is:

[0022] The flashboard 1 is arranged on the end face of the machine coke side flue 10 of the coke oven. The cross section of the gate 1 and the machine coke side flue is parallel. Space for adjusting the gate 1 up and down;

[0023] Boss 100 is provided with side fixing frame 21 and middle fixing frame 22, respectively establishes a side fixing frame 21 on both sides of boss 100, and the middle part of boss 100 is provided with middle fixing frame 22, and the both sides of flashboard 1 and The side fixing frame 21 fits together, the middle part of the gate plate 1 and the middle fixing frame 22 fit together, and between the gate plate 1 and the side fixing frame 21, and between the gate plate 1 and the middle fixing frame 22 are all fixed with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com