Plate shape control method for online solution treatment of steel plates

A solid solution treatment and shape control technology, which is applied in the field of metallurgy, can solve problems such as poor shape of steel plates, achieve good shape, save carbon emissions and a lot of energy consumption, and have compact and energy-saving cooling devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0071] The main parameters of a specific embodiment of the cooling system after rolling for on-line solid solution of the present invention are as follows:

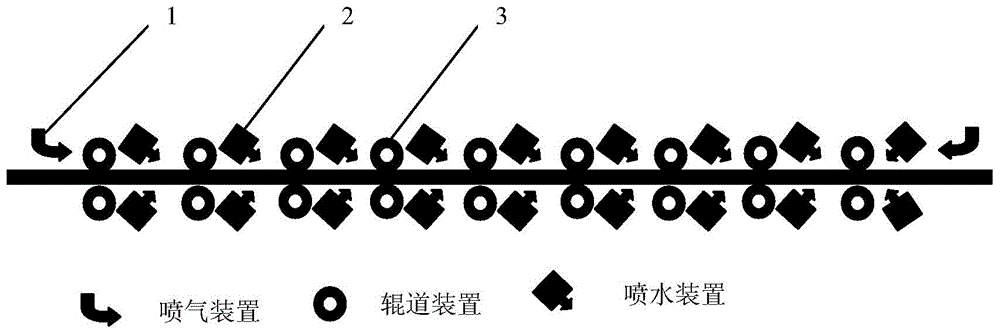

[0072] 1) Roller technical parameters (refer to image 3 shown)

[0073]

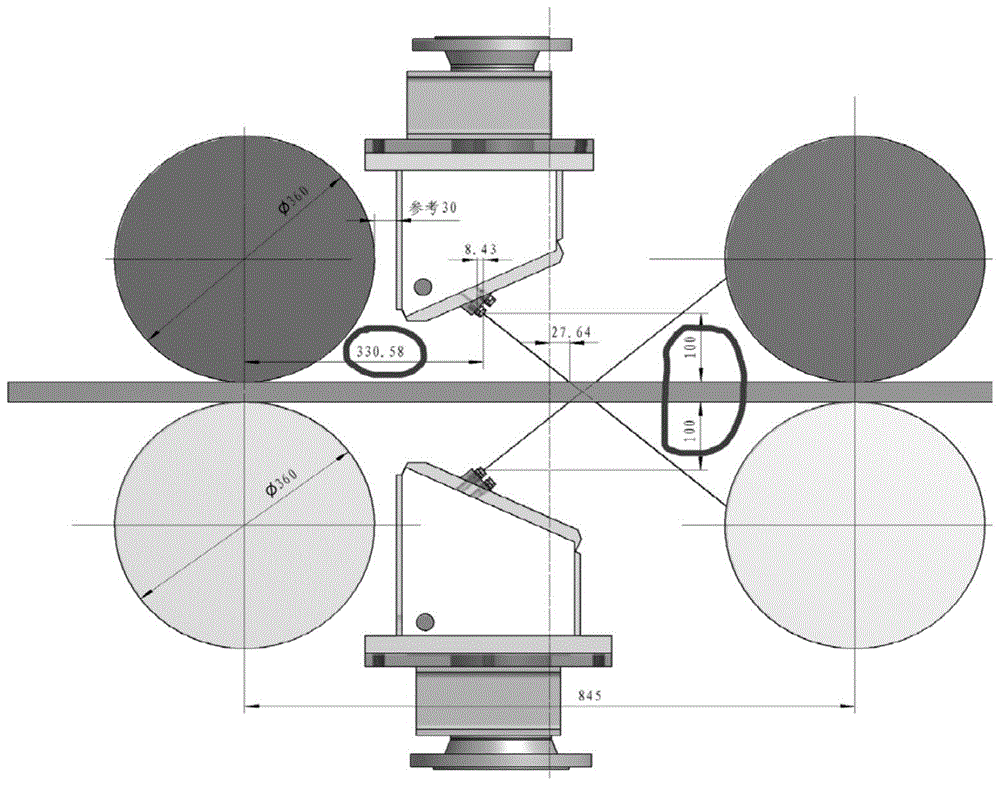

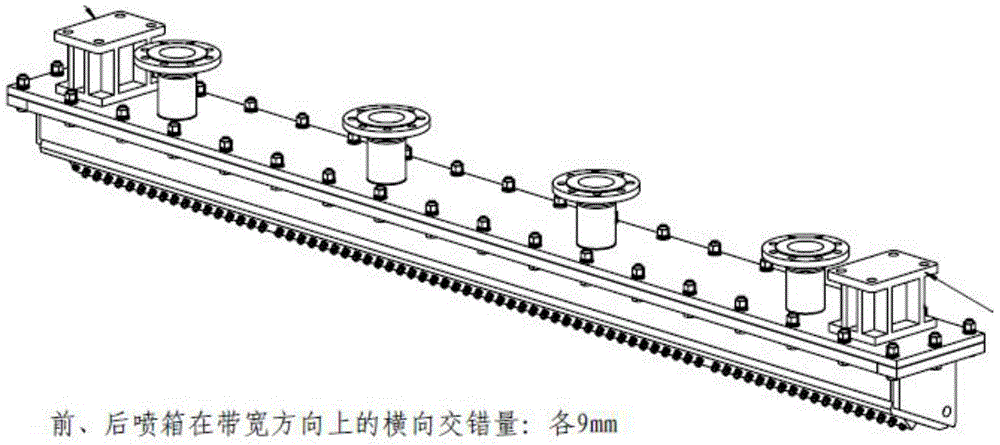

[0074] 2) Technical parameters of the spray box (refer to figure 1 , figure 2 shown)

[0075] Nozzle distance from roller surface: 100mm

[0076] Spray angle: 30°

[0077] 3) Technical parameters of medium pressure water system

[0078] 2 groups each up and down

[0079] Water inlet pressure 1.0MPa

[0080] The total water volume on the spray box is about 0~495m 3 / h

[0081] The lower spray box is about 0~623m 3 / h

[0082] 4) Technical parameters of low pressure water system

[0083] Quantity 14 groups up and down

[0084] Water inlet pressure 0.5MPa

[0085] The total water volume on the spray box is about 0~1680m 3 / h

[0086] The lower spray box is about 0~2116m 3 / h

[0087] 5) Valve group design and flow setting

[008...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com