Post-rolling fast cooling system for on-line solution treatment of steel plates

A rapid cooling and steel plate technology, applied in the direction of metal rolling, metal rolling, metal processing equipment, etc., can solve the problems of difficult precise steel placement and automatic control, waste of resources, uneven cooling, etc., to protect the safety of operation and Long service life, saving carbon emissions and a lot of energy consumption, compact and energy-saving cooling device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

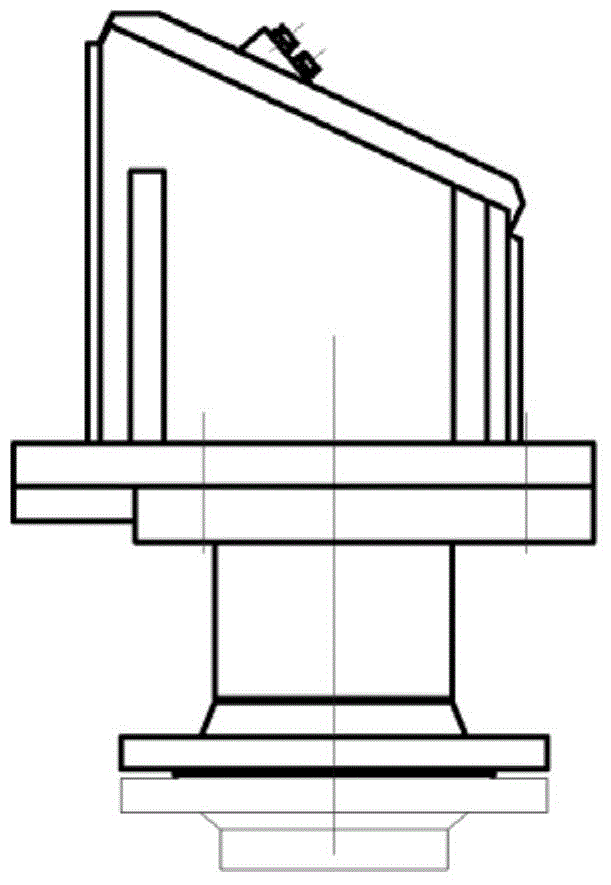

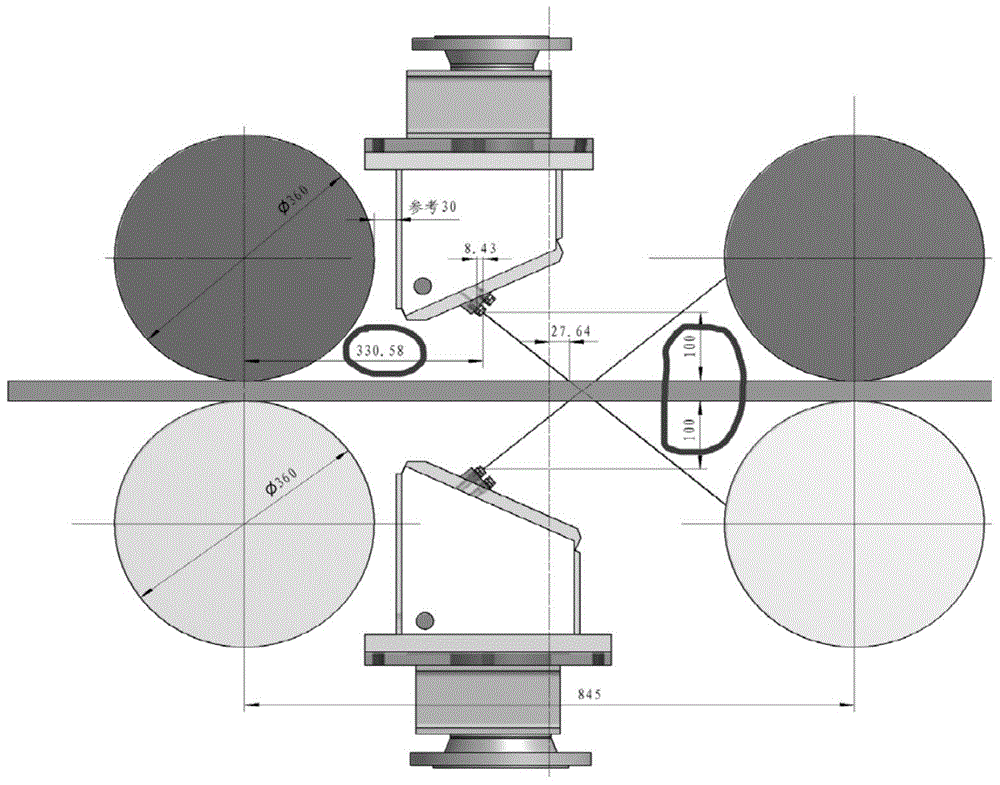

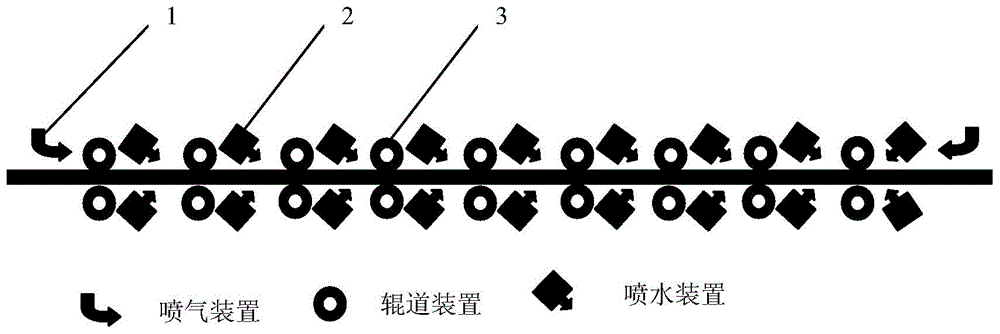

[0123] The main parameters of a specific embodiment of the post-rolling cooling system are as follows:

[0124] 1) Overall technical parameters

[0125] Total length of quick cooling device: 13978mm

[0126] Cooling water demand: 4360m 3 / h (using the water supply technology of the present invention, the water supply capacity can only be 2500m 3 / h to meet the cooling demand)

[0127] Opening and cooling temperature: 950°C

[0128] Final cooling temperature: <200°C

[0129] Thickness range: 10-100mm (using the water supply technology, underwater tracking technology and swing cooling mode of the present invention, the continuous water supply in the cooling process of thick steel plates under low water supply capacity is realized)

[0130] 2) Detection of technical parameters of roller table:

[0131]

[0132] 3) Technical parameters of conveying roller table:

[0133]

[0134] 4) Technical parameters of medium pressure water system:

[0135]

[0136]

[0137...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com