Antibacterial and non-dyeing ecological multi-color series yarn and fabric

A kind of yarn and multi-technology, applied in the field of antibacterial and dye-free ecological multi-color series yarns and fabrics, can solve the problems of people's troubles and affect the ecological environment, and achieve the effects of improving wearing comfort, improving moisture absorption, and stable dyeing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1) Spinning

[0025] (1) Spinning specifications

[0026] The blending mass ratio of copper modified polyester fiber / original viscose fiber / other fibers is: 41% / 0% / 59%

[0027] The antibacterial and non-dyed ecological multi-colored yarn is 14.8tex.

[0028] (2) Process flow

[0029] Copper-modified polyester fiber 41% + other fibers (cotton) 59% (mixed fully and evenly first) → cleaning cotton (including multi-bin blending machine) → carding → drawing (first, second) → roving → Spinning→winding

[0030] In the spinning process of copper-modified polyester fiber, antistatic treatment process is also required. The antistatic process is to spray the antistatic agent evenly on the copper-modified polyester fiber in the form of spray before the cleaning process. Put it on polyester fiber, then wrap it with plastic film, and place it for 24 hours at a temperature above 20°C;

[0031] (2) Weaving:

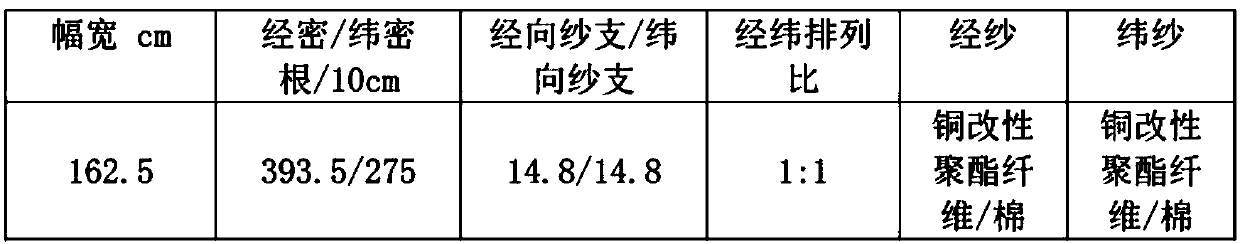

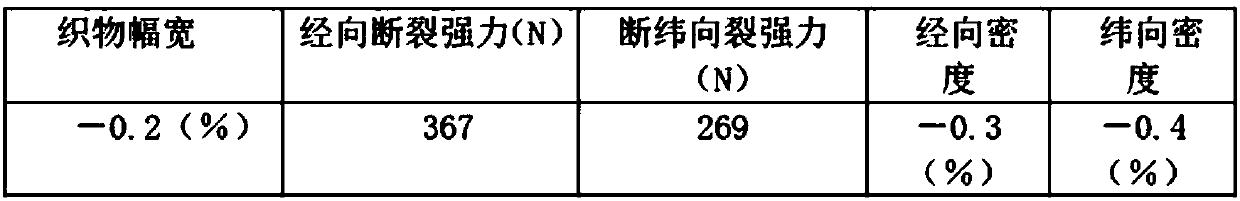

[0032]

[0033] Antibacterial and non-dyed ecological multi-colored...

Embodiment 2

[0043] (1) Spinning

[0044] (1) Spinning specification

[0045] The blending mass ratio of copper modified polyester fiber / original viscose fiber / other fibers is: 0% / 70% / 30%

[0046] The antibacterial non-dyed ecological multi-colored yarn is 9.8tex.

[0047] (2) Process flow

[0048] Raw viscose fiber 70% + other fibers (modal) 30% (first artificially mixed evenly) → cleaning cotton (including multi-bin blending machine) → carding → drawing (first, second) → roving → spun yarn → Winding

[0049] (3) Weaving:

[0050]

[0051] Antibacterial and non-dyed ecological multi-colored fabric, antibacterial and non-dyed ecological multi-colored fabric is woven from antibacterial and non-dyed ecological multi-colored yarn through the steps of warping, sizing, drafting and weaving; the specific steps are as follows:

[0052] (a) Warping: Antibacterial non-dyed ecological multi-colored yarns are warped in batches, wound into pulp shafts, the warping speed is 300 m / min, and the har...

Embodiment 3

[0061] (1) Spinning

[0062] (1) Spinning specification

[0063] The blending mass ratio of copper modified polyester fiber / original viscose fiber / other fibers is: 0% / 100% / 0%

[0064] The antibacterial non-dyed ecological multi-colored yarn is 19.5tex.

[0065] (2) Process flow

[0066] 100% original viscose fiber→opening and cleaning (including multi-bin blender)→carding→drawing (first and second parallel)→roving→spinning→winding

[0067] (2) Weaving:

[0068]

[0069] The antibacterial non-dyed ecological multi-colored fabric is characterized in that: the antibacterial non-dyed ecological multi-colored fabric is woven from antibacterial and non-dyed ecological multi-colored yarns through the steps of warping, sizing, drafting and weaving; Proceed as follows:

[0070] (a) Warping: Antibacterial non-dyed ecological multi-colored yarns are warped in batches, wound into pulp shafts, the warping speed is 350 m / min, and the hardness of the pulp shafts is 73%; the tension o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com