Disperse blue-to-black dye composition

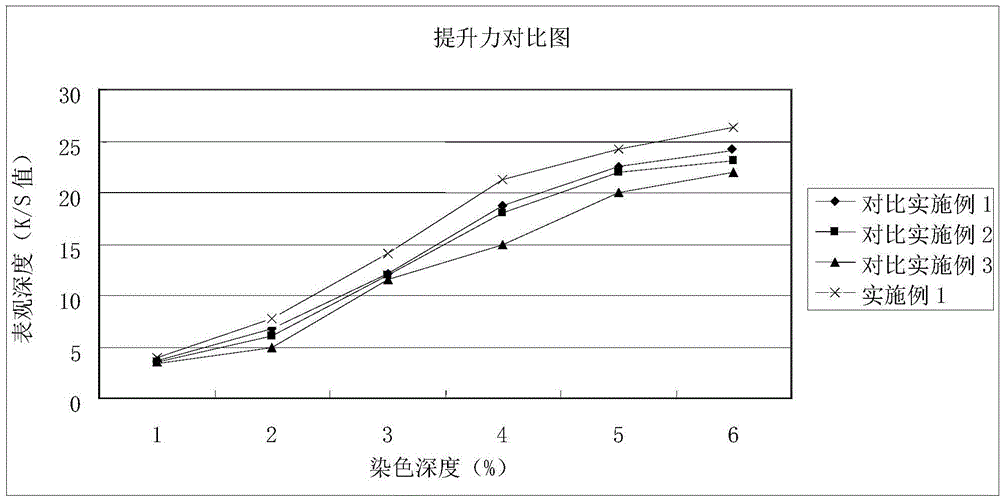

A technology for black dyes and dye compounds, applied in the field of disperse dye compositions, can solve the problems of few varieties of alkali-resistant disperse dyes and high prices, and achieve the effects of stable dyeing performance, good lifting power and excellent color fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

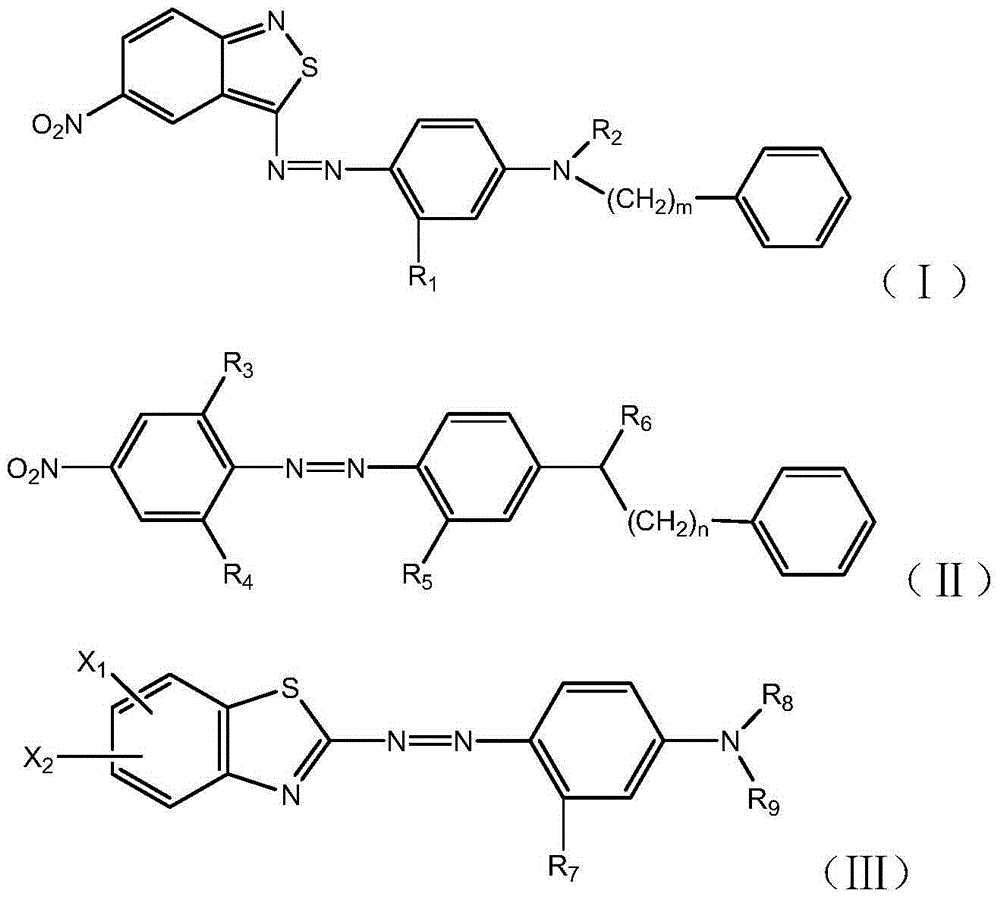

Method used

Image

Examples

Embodiment l

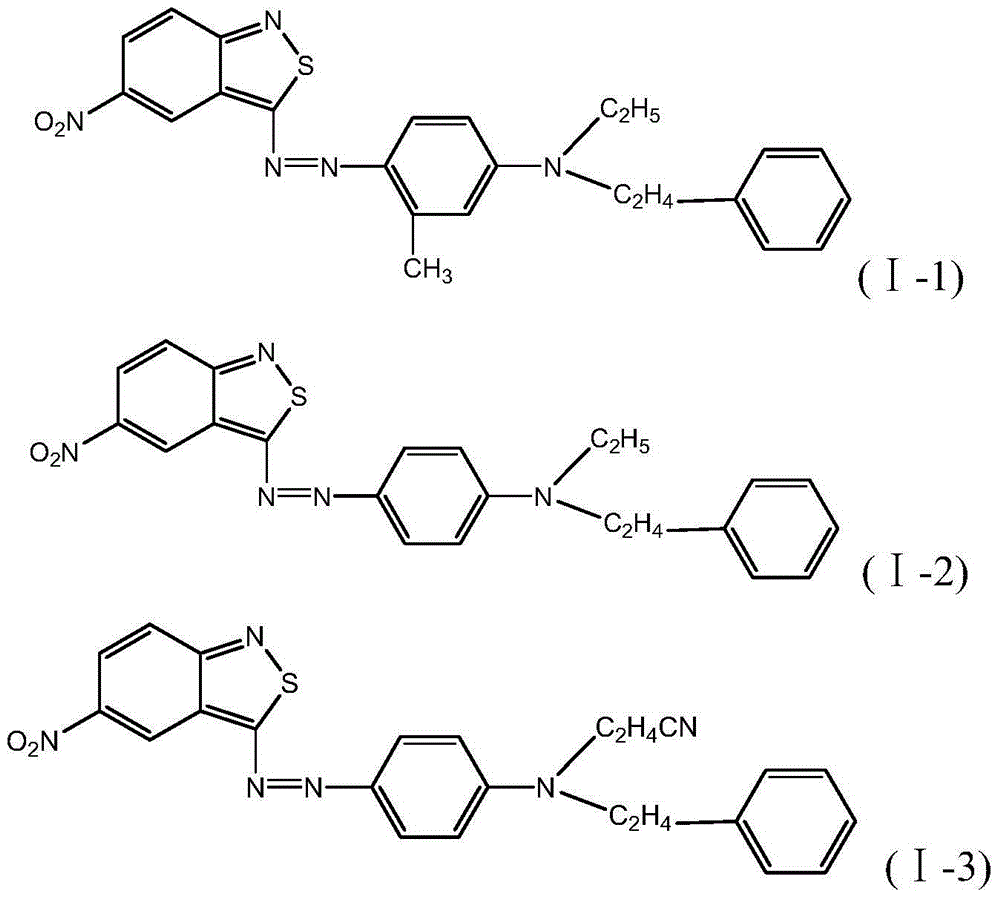

[0041] After mixing 47 grams of formula (I-1), 40 grams of formula (II-1), 13 grams of formula (III-1), 200 grams of dispersant MF, adding 550 grams of water, grinding, dispersing, and drying, the finished product is obtained , The finished product can provide fabric black tones.

Embodiment 2

[0043] After mixing 85 grams of formula (I-1), 10 grams of formula (II-1), 5 grams of formula (III-2), 250 grams of dispersant MF, and 600 grams of water, they are ground, dispersed, and dried to obtain the finished product. The finished product can provide fabric blue hue

Embodiment 3~28

[0045] According to the method described in Example 1 or 2, the difference is that the weight ratio of component A, component B, and component C in Table 1 and additives are used and mixed with water to form a slurry to control the solid content of the slurry. It is suitable to be 35-45%, grind, disperse, and dry to obtain a finished product, which can provide the fabric with uniform blue to black color tone with good fastness performance. 85A and 83A in Table 1 are lignin 85A and lignin 83A, respectively.

[0046] Table 1

[0047]

[0048]

[0049] Dyeing application 1:

[0050] Weigh 4g of the disperse dye prepared in Example 1 and disperse it in 500ml of water, absorb 20ml and mix with 100ml of water, adjust the pH to 12.5 with caustic soda, put 4g of polyester fabric, and heat to 70°C. Continue to increase the temperature to 130°C with a gradient of about 2°C / min, and keep the temperature for 45 minutes. Then cool to about 80℃, wash with hot water for 10 minutes, and dry. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com