Cast-in-situ cavity floor adopting steel net cages with ribs

A cavity floor and steel mesh engraving technology, which is applied to floors, building components, buildings, etc., can solve the problem of not being able to cooperate with the floor to bear force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The invention will be further described below in conjunction with the accompanying drawings.

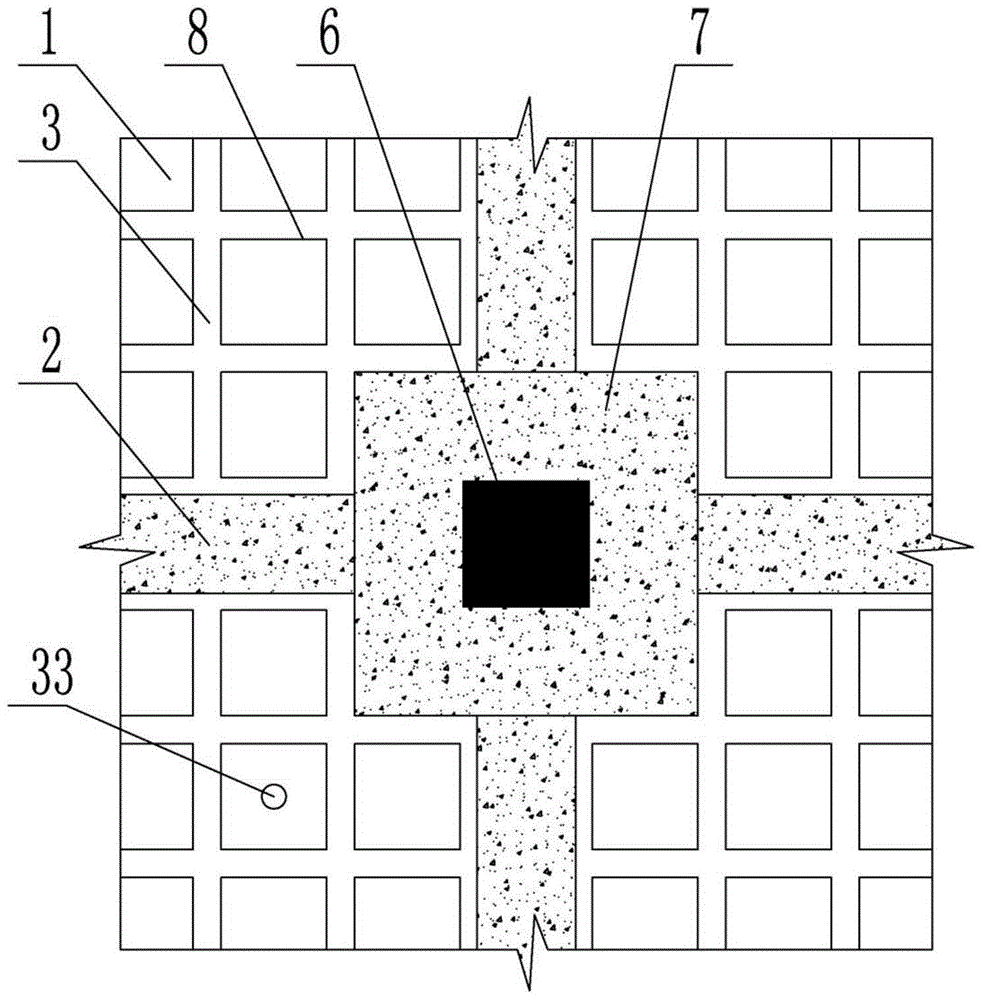

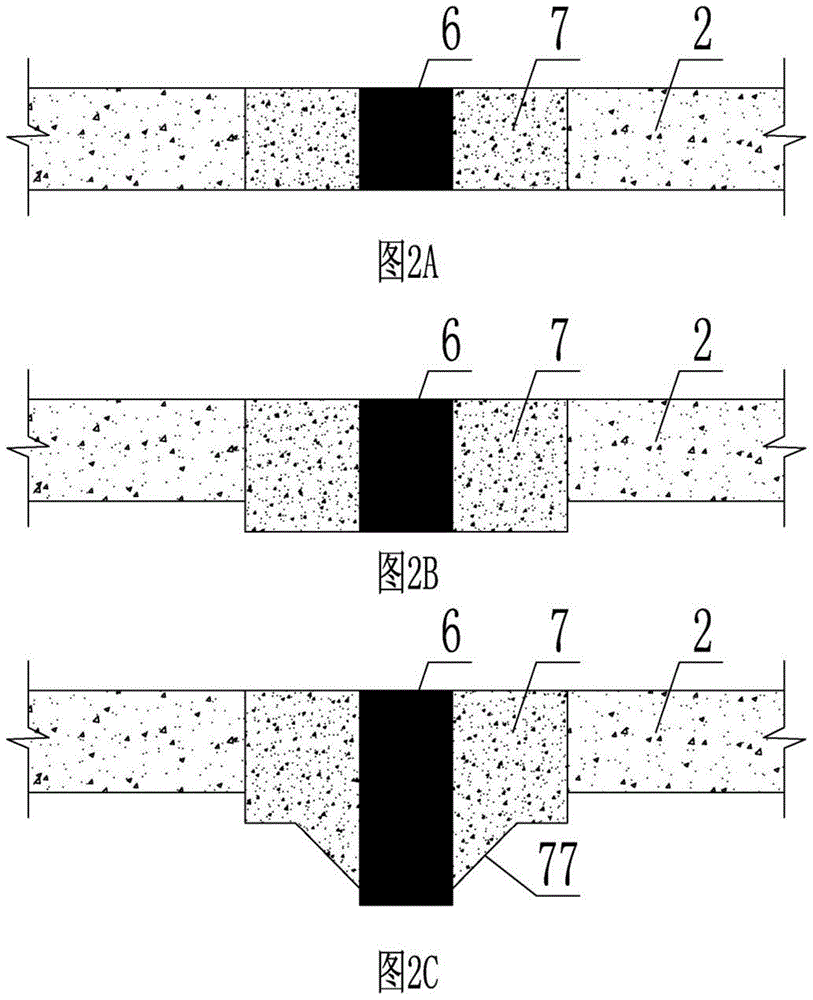

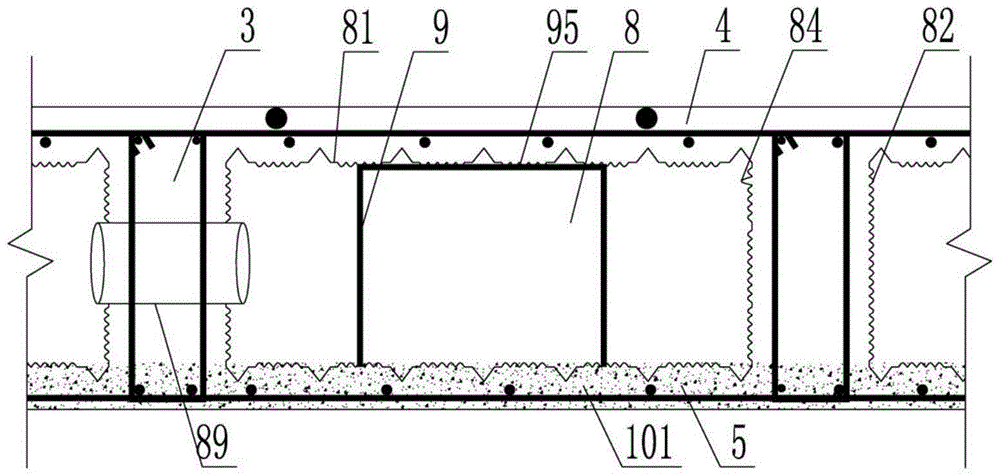

[0022] figure 1It is a plane structure diagram of a cavity floor cast-in-place hollowed out with ribbed steel mesh according to the present invention. When the present invention is implemented, floor steel bars are laid on the cavity floor formwork with an "I-shaped" stress section, and the rib steel bars are bound 3. Bundle the main beam steel bar 2 and the column steel bar 6 to form a column network; add auxiliary steel bars to resist shearing at the junction of the column 6 and the main beam 2 to form a structural platform 7 for the column 6 and the main beam 2; The steel bars are bound into a grid of ribbed beams, and ribbed steel meshes 8 are placed in the grids of ribbed beams 3. The ribbed steel meshes 8 are made according to the specifications and sizes required by the architectural design. The technology of the present invention is purely mechanized. Ribbed steel mes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com