Gun ammunition

a technology of gun ammunition and cartridges, applied in the field of gun ammunition, can solve the problems of affecting the firing range of the gun, and achieve the effect of high fire ra

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

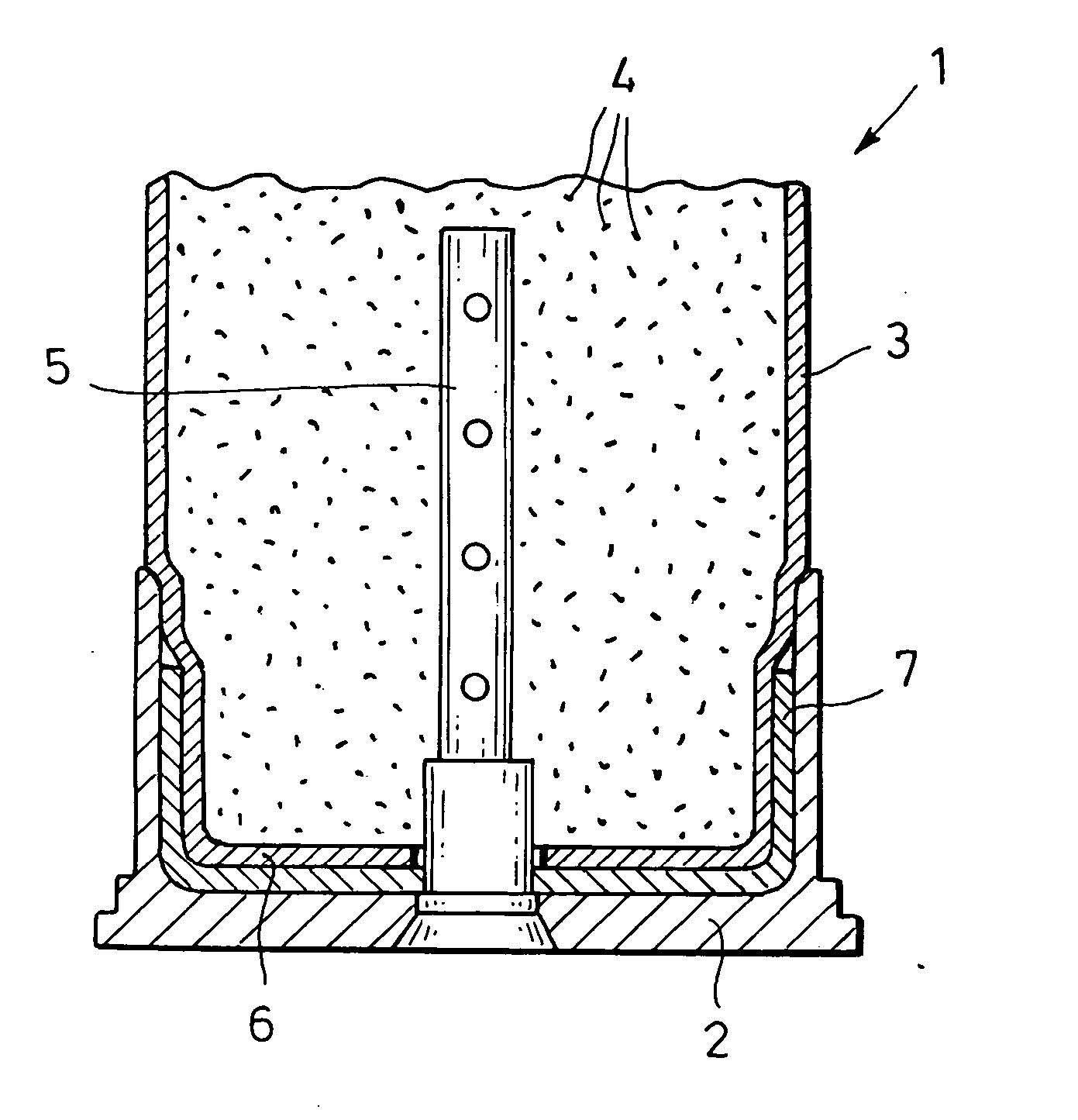

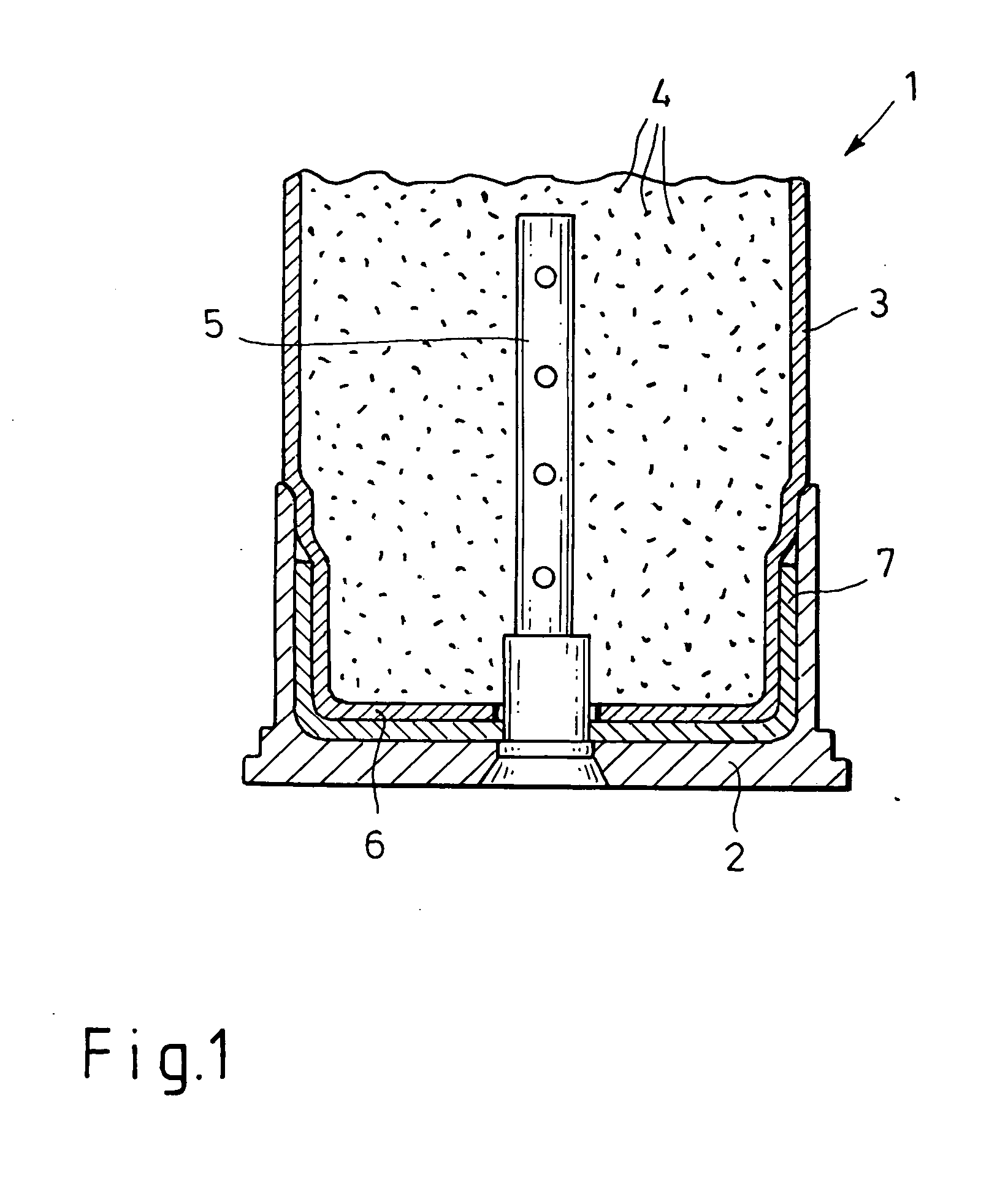

[0016]FIG. 1 shows the bottom region 1 of a cartridge, having a case bottom 2 of metal and a combustible case 3. The propellant powder 4 within the combustible case 3 can be ignited with a centrally located propellant igniter 5.

[0017] According to the invention, a collar 7 that comprises an oxygen-releasing substance is arranged between the case bottom 2 and a cartridge-bottom region 6 of the combustible case 3.

[0018] Thus, if the cartridge 1 is positioned inside a gun barrel (not shown), then the propellant powder 4 is initially ignited with the propellant igniter 5, following the firing. The case 3 subsequently burns and sufficiently heats up the collar 7, so that it begins to release oxygen into the bottom region of cartridge 1 and thus also into the breech area of the gun.

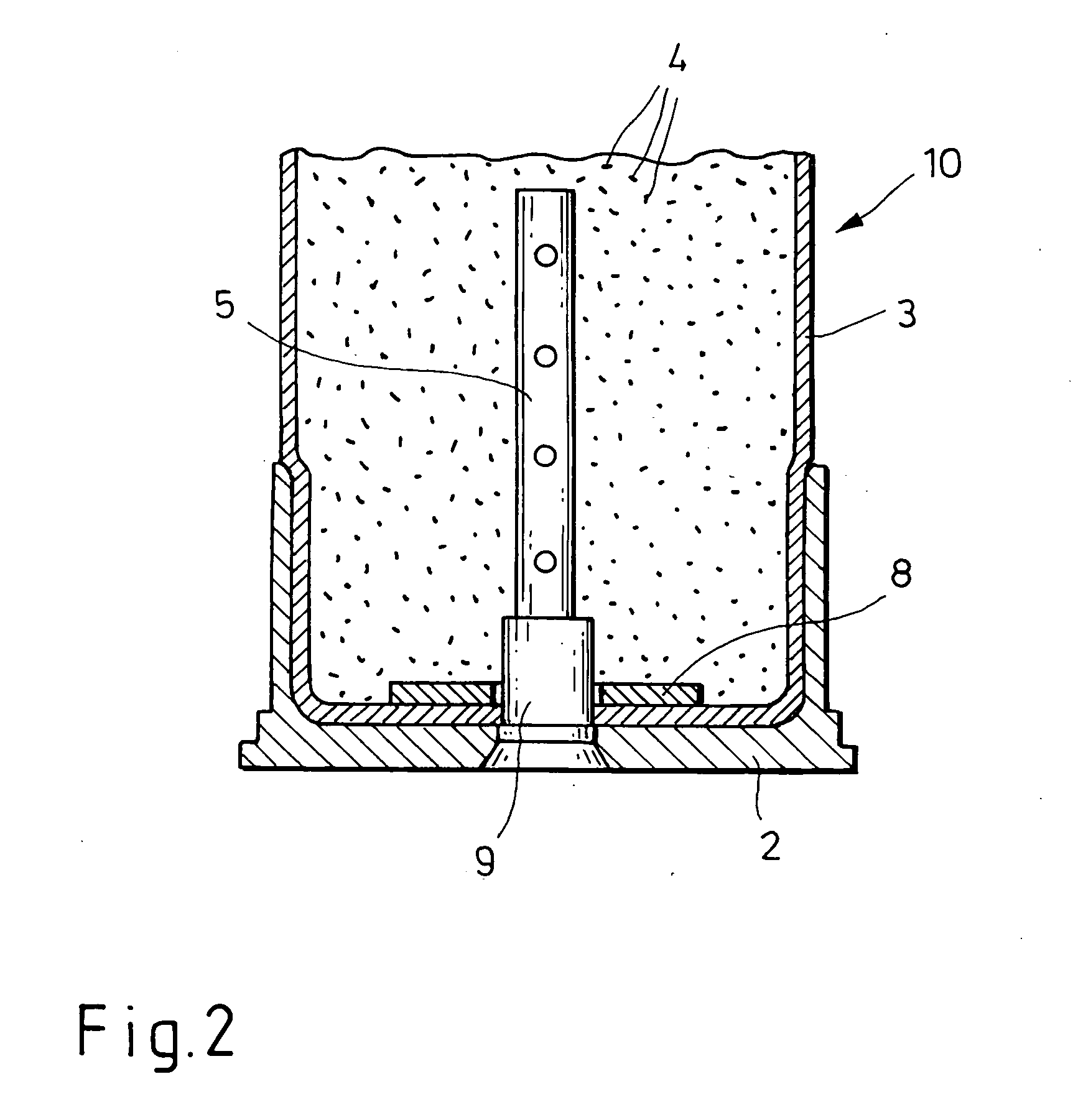

[0019]FIG. 2 shows another exemplary embodiment of the invention, for which an oxygen-releasing substance takes the form of a ring-shaped element 8 that is positioned on the bottom part 9 of the propellant i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| combustion behavior | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com