Apparatus for multi-directional pressure-controlled spray seal pressure and pipe string containing same

A pressure control and nozzle technology, applied in the directions of sealing/isolation, production fluids, wellbore/well components, etc., to achieve the effect of reducing operating procedures, simplifying operating procedures, and reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described below in conjunction with accompanying drawing.

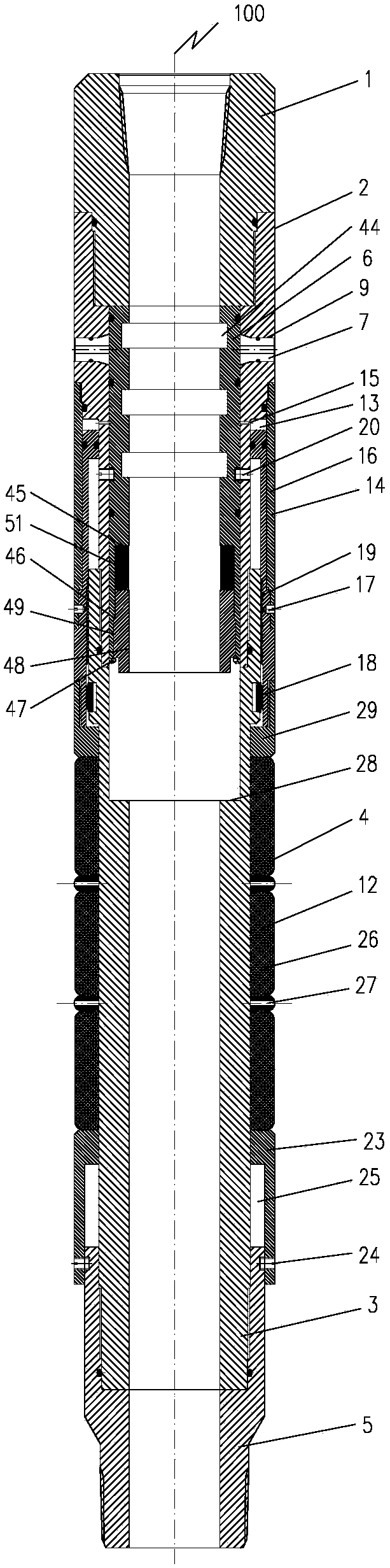

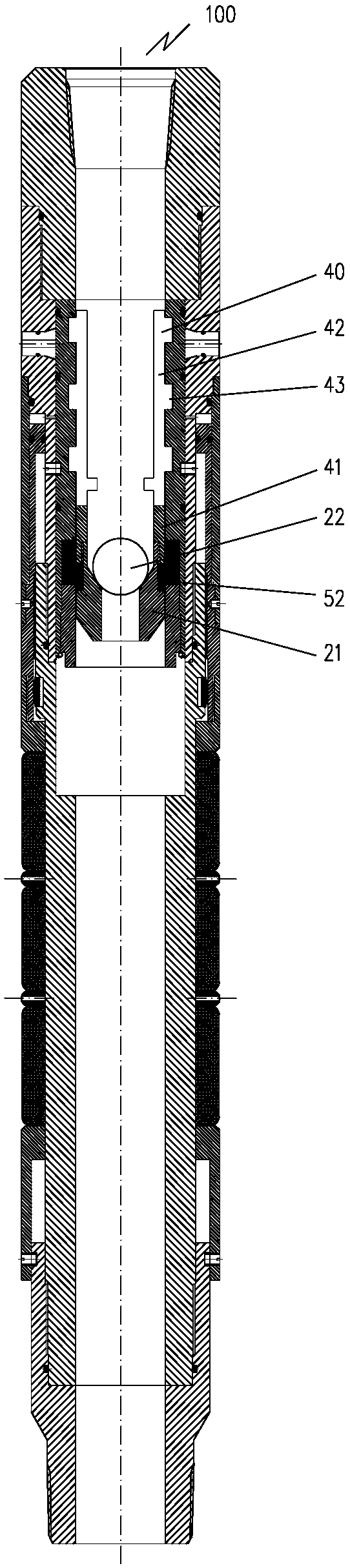

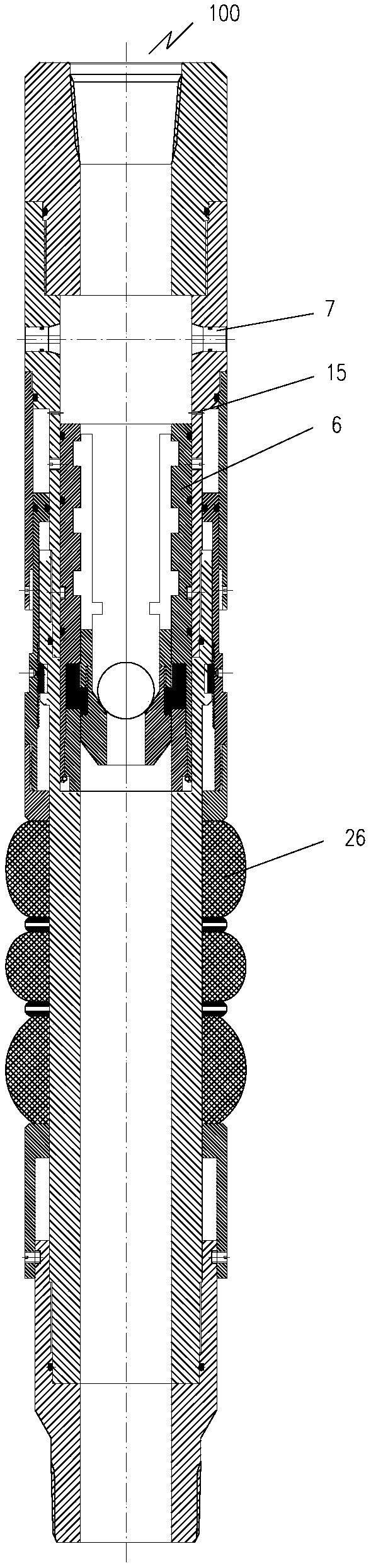

[0042] figure 1 A device 100 for multi-directional pressure controlled spray seal pressure according to an embodiment of the present invention is shown. Such as figure 1 As shown, the device 100 includes an upper joint 1, a nozzle sleeve 2, a central rod 3, a packer 4, a lower joint 5, an inner cylinder 6, a nozzle 7 and an opening tool 40 (in figure 2 shown in ). Wherein, the upper joint 1 is configured in a cylindrical shape, and is used to connect with the tubing 8 to send the device 100 into the reservoir. The nozzle cover 2 is arranged at the lower end of the upper joint 1 and is configured in a cylindrical shape. At the same time, a flow hole 9 communicating with the inside and the outside is provided on the peripheral wall of the nozzle cover 2 . The central rod 3 is arranged on the lower end of the nozzle cover 2 and is cylindrical. The packer 4 is arranged o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com