Torque transmission device for a drive train of a motor vehicle and drive train of a motor vehicle

A technology of torque transmission device and motor vehicle, applied in mechanical equipment, elastic coupling, coupling and other directions, can solve problems such as damage to the drive train, shorten the service life of the drive train, etc., and achieve the effect of eliminating radial deflection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

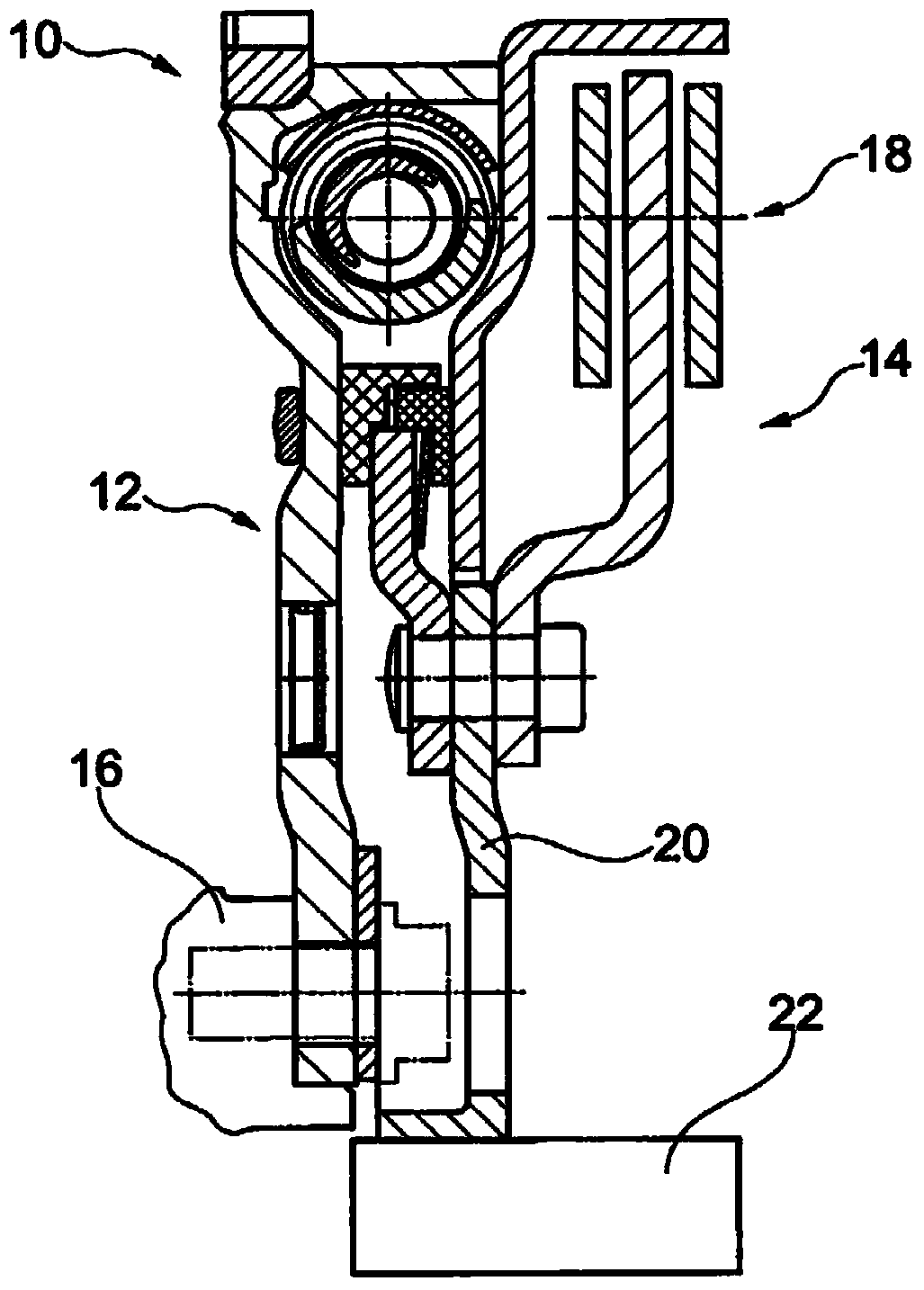

[0025] FIG. 1 shows a cross-sectional view of a torque transmission device 10 according to the prior art. The torque transmitting device 10 is a dual mass flywheel including a primary side 12 and a secondary side 14 . The primary side is connected to a drive shaft 16 of a motor vehicle engine, not shown. The secondary side 14 has a centrifugal pendulum 18 and a hub 20 . The hub 20 is connected on the output side of the secondary side 14 via an intermediate shaft 22 to a transmission input shaft (not shown). The intermediate shaft 22 is in particular connected to a clutch (not shown) in order to transmit torque to the transmission input shaft.

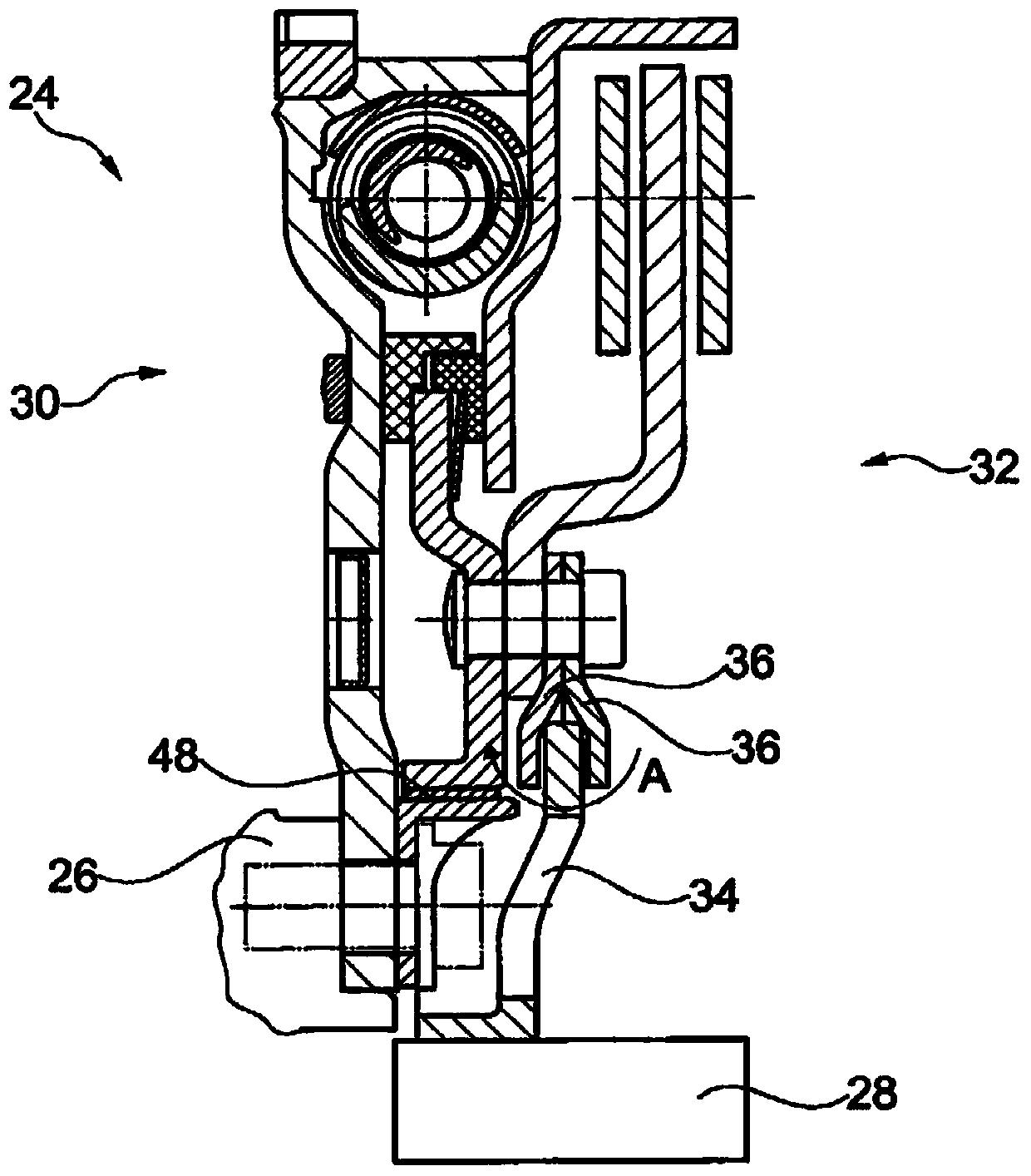

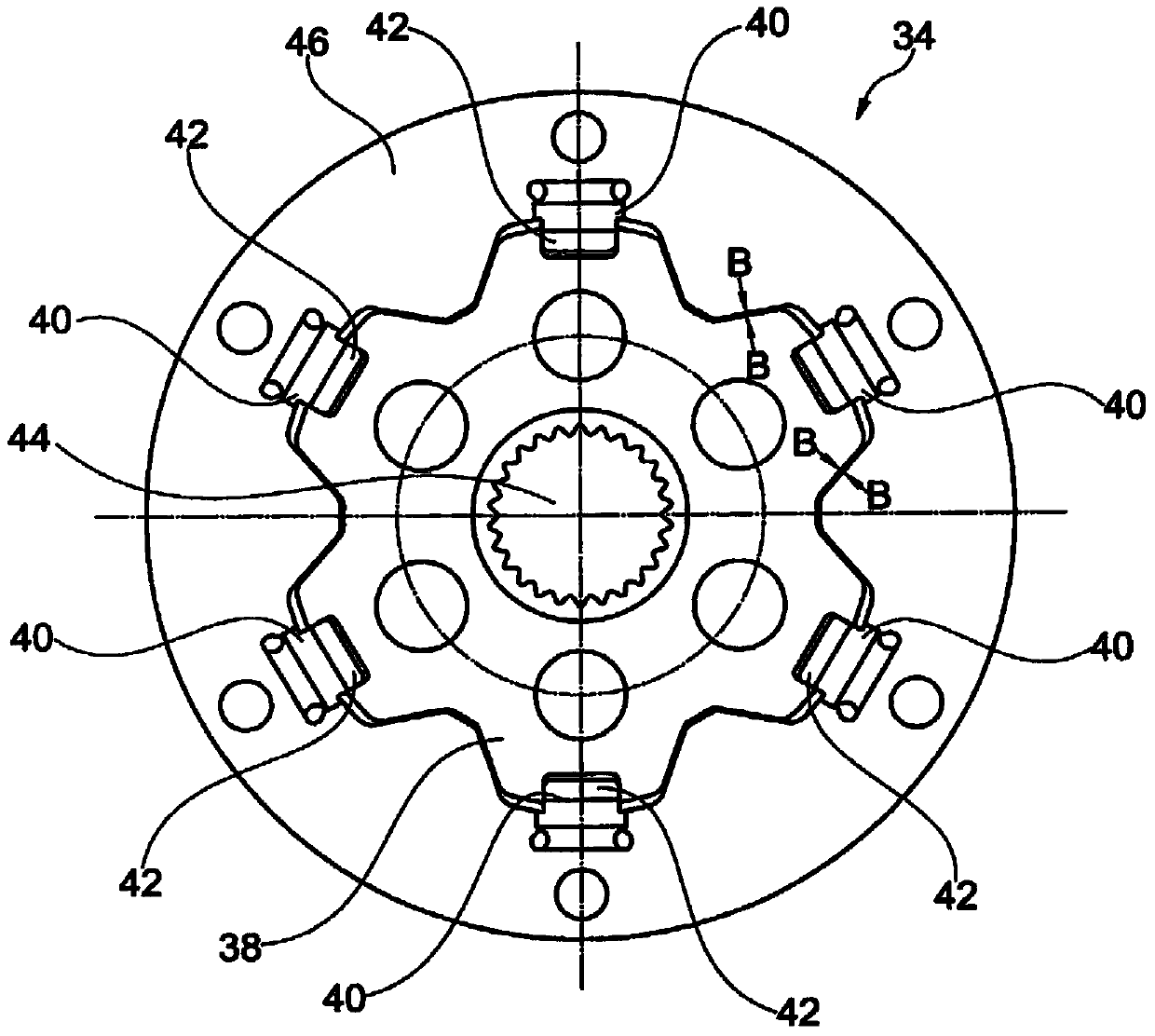

[0026] figure 2 A preferred embodiment of the torque transfer device 24 is shown. The torque transfer device 24 is arranged between a drive shaft 26 and an intermediate shaft 28 of a motor vehicle engine, not shown. The intermediate shaft 28 connects the torque transmission device 24 to a clutch (not shown) and thus to a transmissi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com