Torsional vibration reducing device

A torsional vibration, rotating body technology, applied in the direction of rotational vibration suppression, vibration suppression adjustment, spring/shock absorber, etc., can solve problems such as inconvenience, deterioration of damping performance, increase in axial length, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

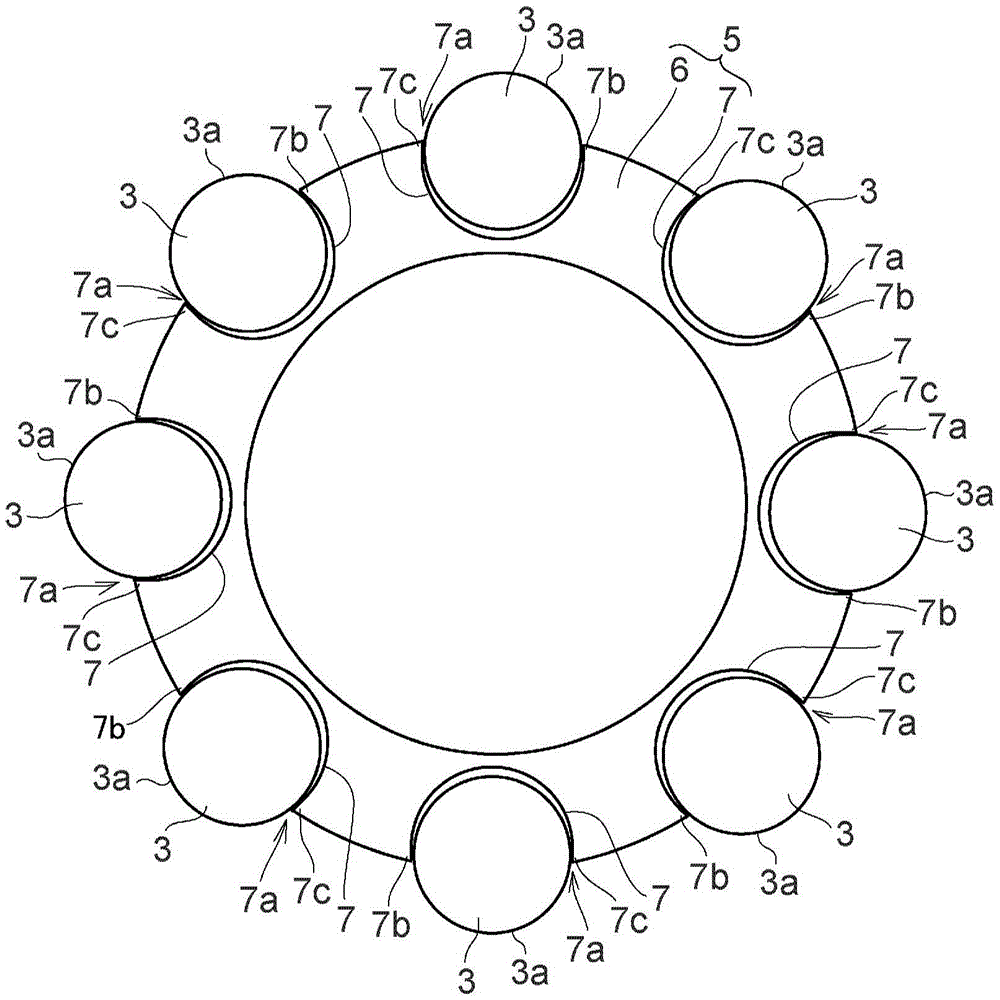

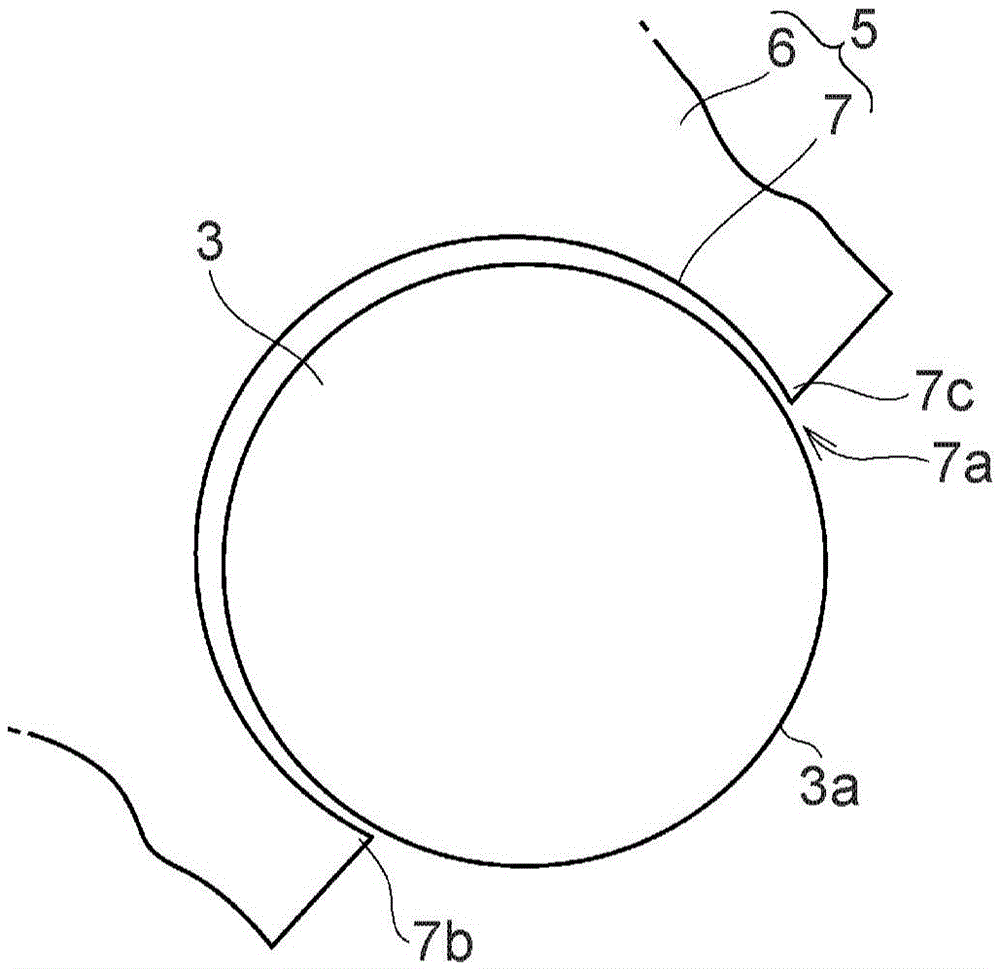

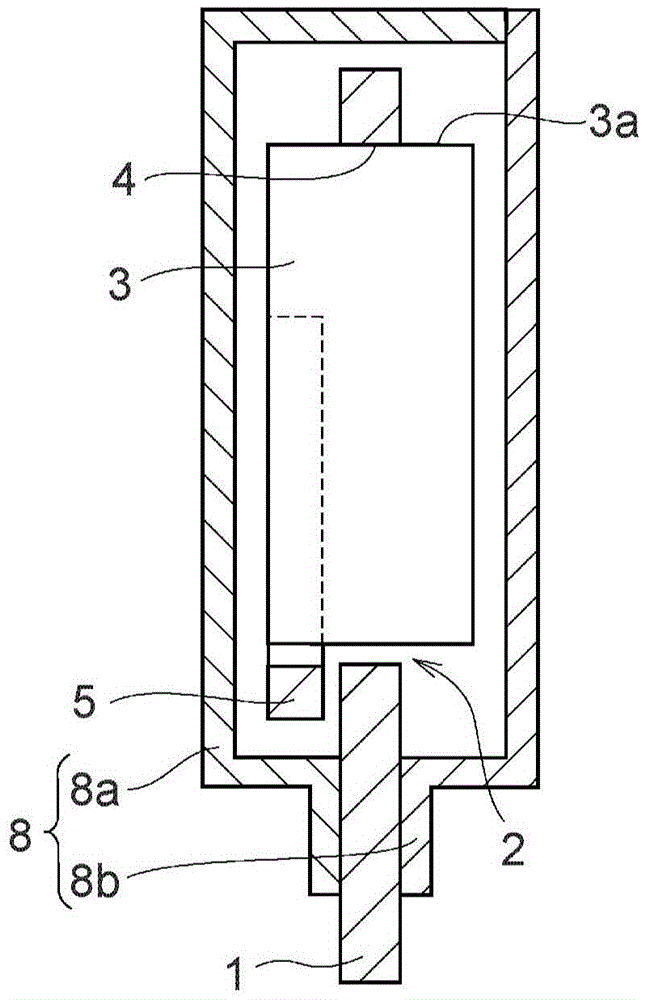

[0024] image 3 is a sectional view showing a part of one example of the torsional vibration reducing device according to the first embodiment. The torsional vibration reducing device includes a rotating body 1 attached to a shock absorbing object. The rotating body 1 is a disc-shaped member. The circumferentially long guide hole 2 is formed at a position radially offset from the rotation center of the rotary body 1 . The guide hole 2 is formed to penetrate the rotating body 1 in the plate thickness direction. The guide holes 2 are positioned with predetermined intervals in the circumferential direction of the rotating body 1 . As an example, eight guide holes are provided. The guide hole 2 has a shape formed by bending an oval or an ellipse.

[0025] A rolling body 3 reciprocating by inertial force when torque transmitted to the rotary body 1 fluctuates is inserted into each of the guide holes 2 . The rolling body 3 is pressed against the inner surface of the guide hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com