Photovoltaic loop heating pipe assisted twin-heat-source heat-pump heat supply system

A dual heat source, volt loop technology, applied in heating systems, hot water central heating systems, heating fuels, etc., can solve the problem of the mismatch between the evaporator and the condenser, the disadvantage of the evaporator, and the effective use of solar energy and air energy at the same time. Operational performance impact and other issues, to achieve the effect of improving the area of the collector is too large, solving the external power supply, and improving the comprehensive conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

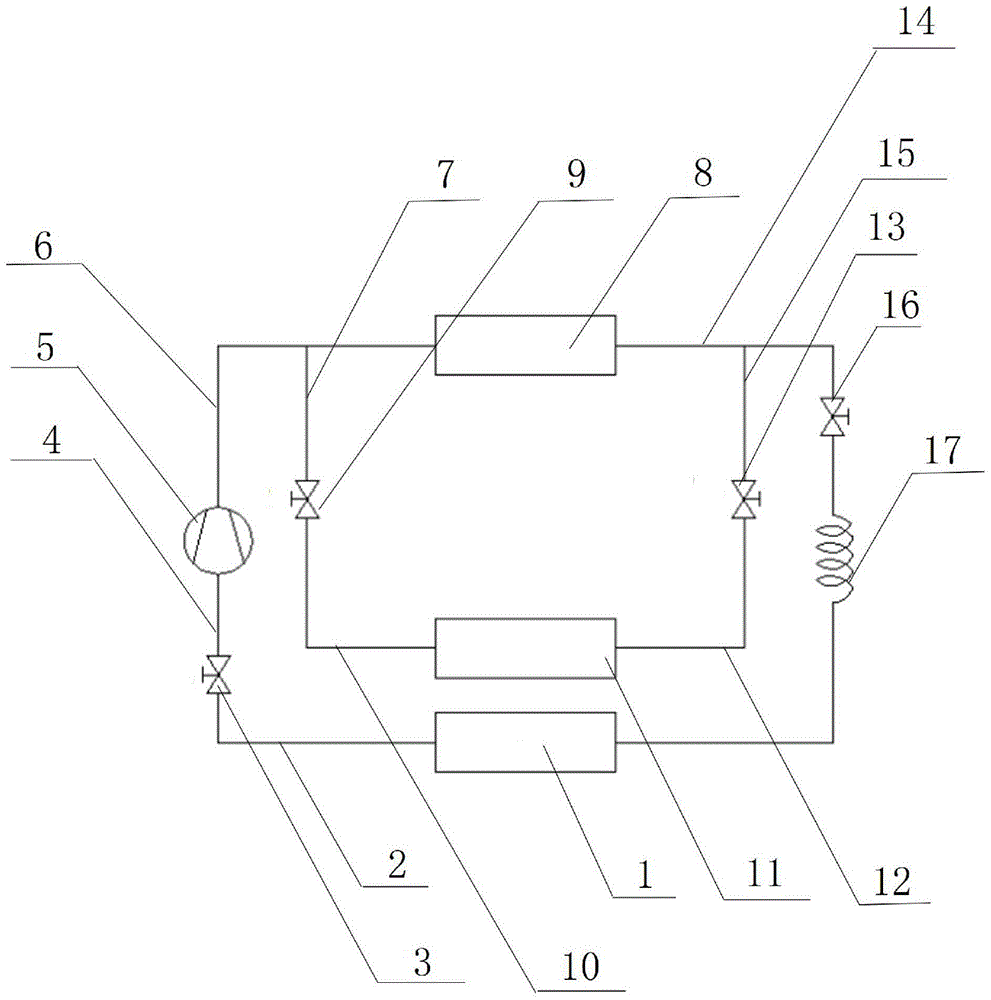

[0012] exist figure 1 In the schematic diagram of the present invention shown, the solar energy / air evaporator 1 is a spiral fin tube heat exchanger, one end of the solar energy / air evaporator is connected with an end of the pipeline A2, and the other end of the pipeline A is connected with the valve A3. One end is connected, the other end of valve A is connected with one end of pipeline B4, and the other end of pipeline B is connected with the air inlet of compressor 5. The gas outlet of the compressor is connected to the pipeline C6 and the pipeline D7 respectively, the gas outlet of the compressor is connected to one end of the condenser 8 through the pipeline C, and the gas outlet of the compressor is connected to one end of the valve C9 through the pipeline D. The other end of the valve C is connected to one end of the solar photovoltaic-loop heat pipe evaporator 11 through the pipeline E10, and the other end of the solar photovoltaic-loop heat pipe evaporator is connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com