Biphase boron-titanium composite layer

A composite layer, boron-titanium technology, applied in the field of wear-resistant infiltration layer, can solve the problems of low efficiency, coarse structure, difficult phase control, etc., and achieve the effect of improving deposition quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] This embodiment provides a dual-phase boron-titanium composite layer, which is prepared in the following manner:

[0040] Step 1) Surface treatment of titanium alloy substrate

[0041] 1) Degreasing: Mix the metal detergent and water to prepare a solution with a concentration of 5%, raise the temperature to 58°C, immerse the titanium alloy substrate in the metal detergent solution, soak for 1.5 hours to remove oil;

[0042] 2) Surface grinding: the surface of the washed titanium alloy substrate is sequentially polished with 400#, 600#, 800#, 1000#, 1200#, 1500#, 2000# water-grinding sandpaper;

[0043] 3) Ultrasonic cleaning: first use acetone as a cleaning agent, and use an ultrasonic cleaning machine to clean the surface-polished titanium alloy substrate at room temperature for 40 minutes; then use deionized water as a cleaning agent, and use ultrasonic cleaning for 40 minutes;

[0044] 4) Plasma cleaning: place the titanium alloy substrate in a PVD device, evacuate ...

Embodiment 2

[0056] This embodiment provides a dual-phase boron-titanium composite layer, which is specific to that of Embodiment 1 only in that:

[0057] In step 4), "heat to 960°C" is replaced with "heat to 980°C".

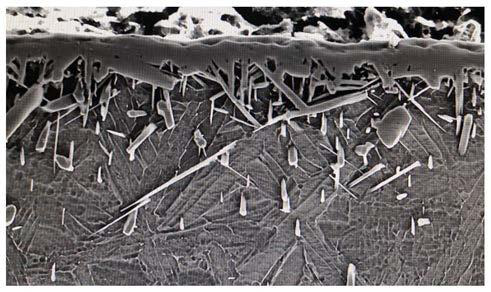

[0058] The TC4 sample after boronizing is detected by scanning electron microscope (SEM). The thickness of the boronizing layer is 50-65um. The boronizing layer on the surface of the sample is dense, well wedged with the substrate, and the growth direction is perpendicular to the substrate.

Embodiment 3

[0060] This embodiment provides a dual-phase boron-titanium composite layer, which is specific to that of Embodiment 1 only in that:

[0061] Use "cold spray" to replace "PVD method" to deposit pure titanium layer;

[0062] Specifically: the process conditions of cold spraying pure titanium prefabricated layer: nitrogen pressure (40~60bar), flow rate (80~95 cubic meters / minute), temperature (950~1100 degrees Celsius), powder feeding amount (50~70g / min) , Carrier gas pressure (5~20bar), carrier gas flow rate (1~9 cubic meters / min), spraying distance (15~35mm).

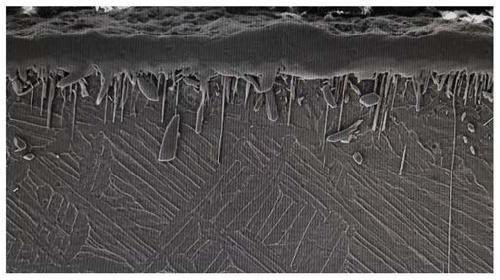

[0063] The TC4 sample after boronizing is detected by scanning electron microscope (SEM). The thickness of the boronizing layer is 60-80um. The boronizing layer on the surface of the sample is dense and well wedged with the substrate, and the growth direction is mostly perpendicular to the substrate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com