Water-based micro-droplet lossless operation device and preparation method

An operating device and micro-droplet technology, which is applied in the direction of manufacturing tools, welding equipment, laser welding equipment, etc., can solve the problems of biologically active material damage, difficulty in non-destructive transfer, and slow droplet movement. The method is simple, Break through the effect of low efficiency and simple additive manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to better understand the present invention, the technical solution of the present invention will be described in detail below with reference to the accompanying drawings and the specific embodiments, and the exemplary examples are intended to be construed as used in the scope of the invention.

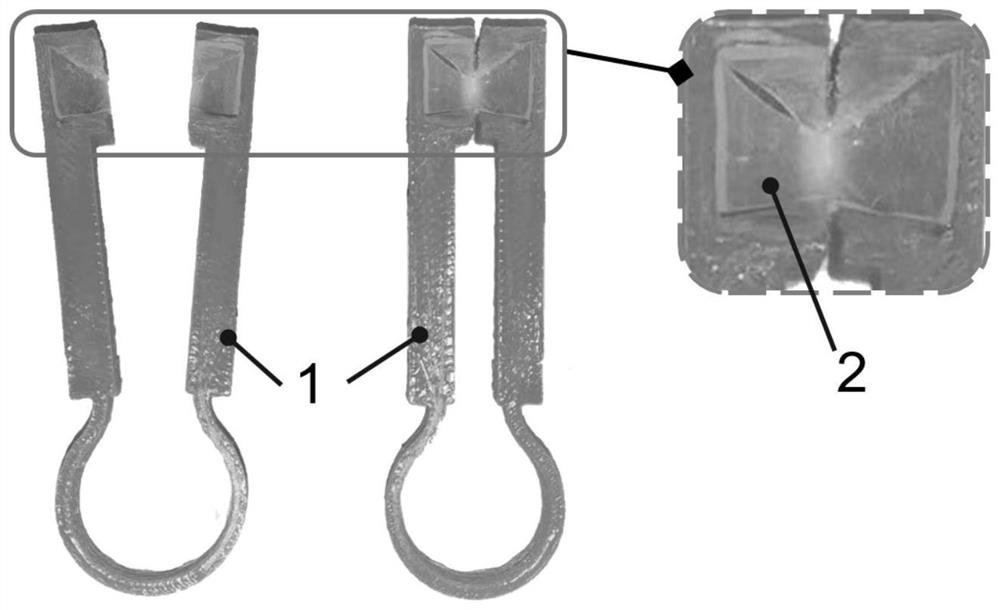

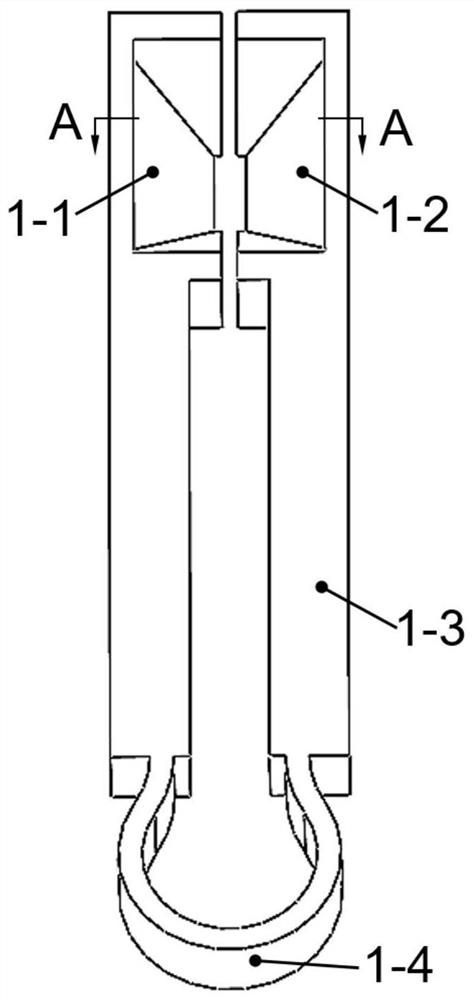

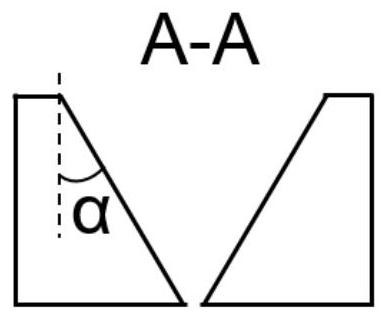

[0030] In this example, a water-based microlicidal droplet lossless operating device based on a low adhesive superhydrophilic function surface includes a low adhesive superhydrophilic film 2 and a clamp base 1; the clamp base 1 includes a first clamping portion. 1-1, the second grip portion 1-2 and the grip portion 1-3, the grip portion 1-3 connects the first clamp portion 1-1, the second grip portion 1-2 in the grip portion Under the control, the first clamp portion 1-1, the second holding portion 1-2 and the water-based microlicidated droplets are grooved, and there is a low-viscous adaptive superhydrophilic film in this surface. 2. By preparing low-adhesive superhydrophi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com