Base device for hydraulic fracturing experiment

A hydraulic fracturing and experimental technology, applied in the field of hydraulic fracturing, can solve the problems of difficulty in ensuring the integrity of rock samples, inability to ensure the in-situ morphology of cracks, and difficulty in ensuring the integrity of samples, and achieves light weight and simple structure. , the effect of small overall size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

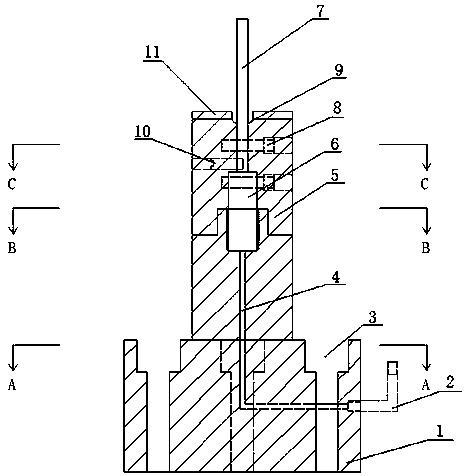

[0027] The specific implementation of the base device will be further described below in conjunction with the accompanying drawings:

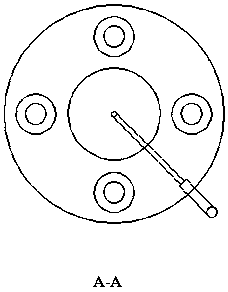

[0028] As shown in Figure 1, the base device proposed by the present invention for fracturing experiments is mainly composed of a base body 1, a transfer elbow 2, a dismantling column 5, a fracturing joint 6, a fracturing steel pipe 7, and a thin metal ring 11 and so on.

[0029] There are connecting holes on the main body 1 of the base, and are connected with the experimental apparatus through four base connecting bolts 3 . There is a flow channel 4 for fracturing fluid in the base body 1, and an adapter elbow 2 is connected to the side of the base body 1 to connect with the flow channel for the circulation of fracturing fluid.

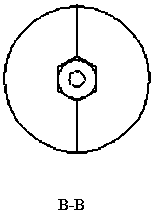

[0030] The lower end of the dismantling post 5 is connected to the outer thread on the base body 1 through its internal internal thread, and the upper end is provided with a thin metal ring 11 as a spacer.

[0031] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com