A kind of sealing test system and sealing test method

A technology for sealing test and detection cavity, which is applied in the direction of liquid/vacuum measurement for liquid tightness, and by measuring the acceleration and deceleration rate of fluid. Detect problems such as damage, and achieve the effect of fast test speed, easy operation and short test cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

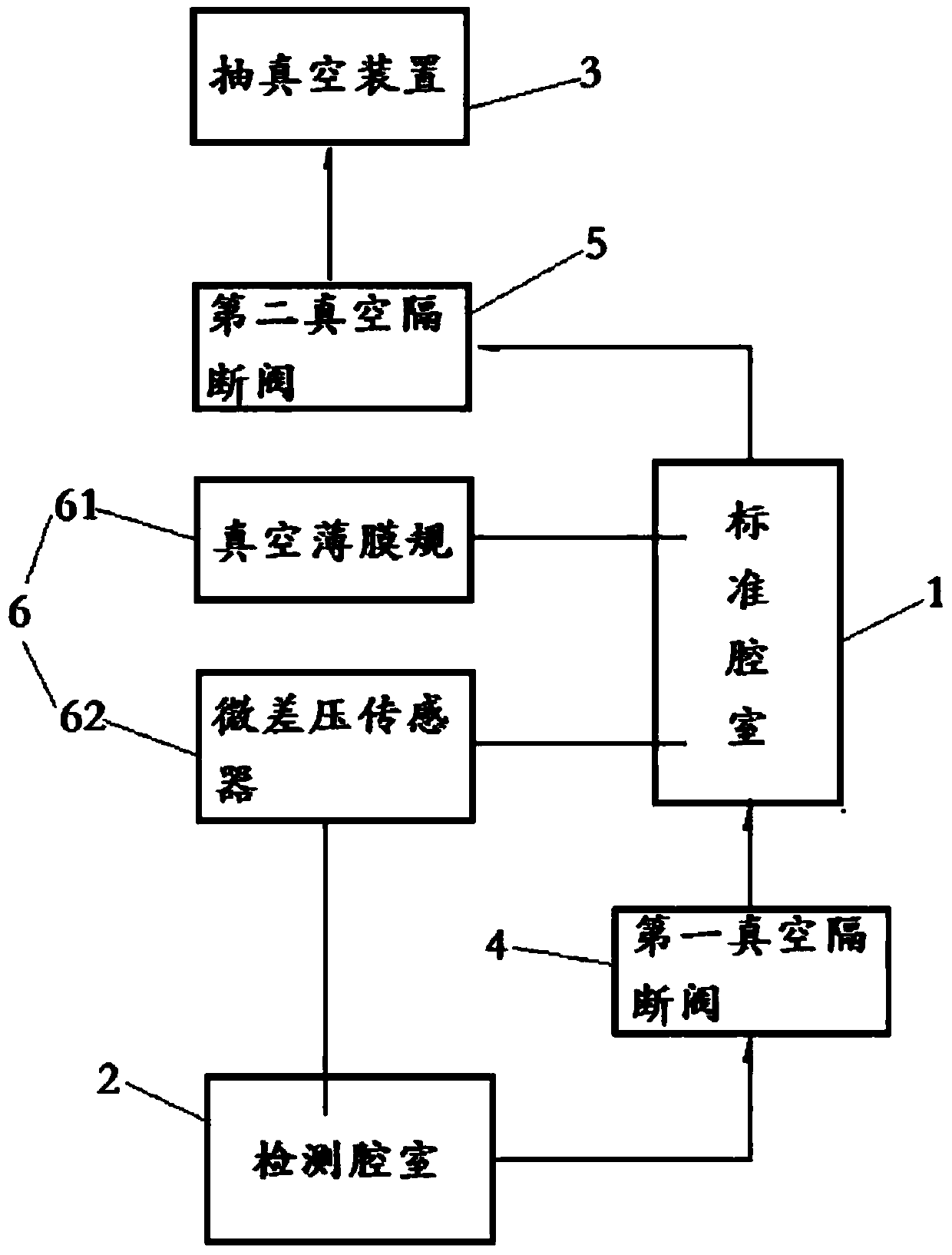

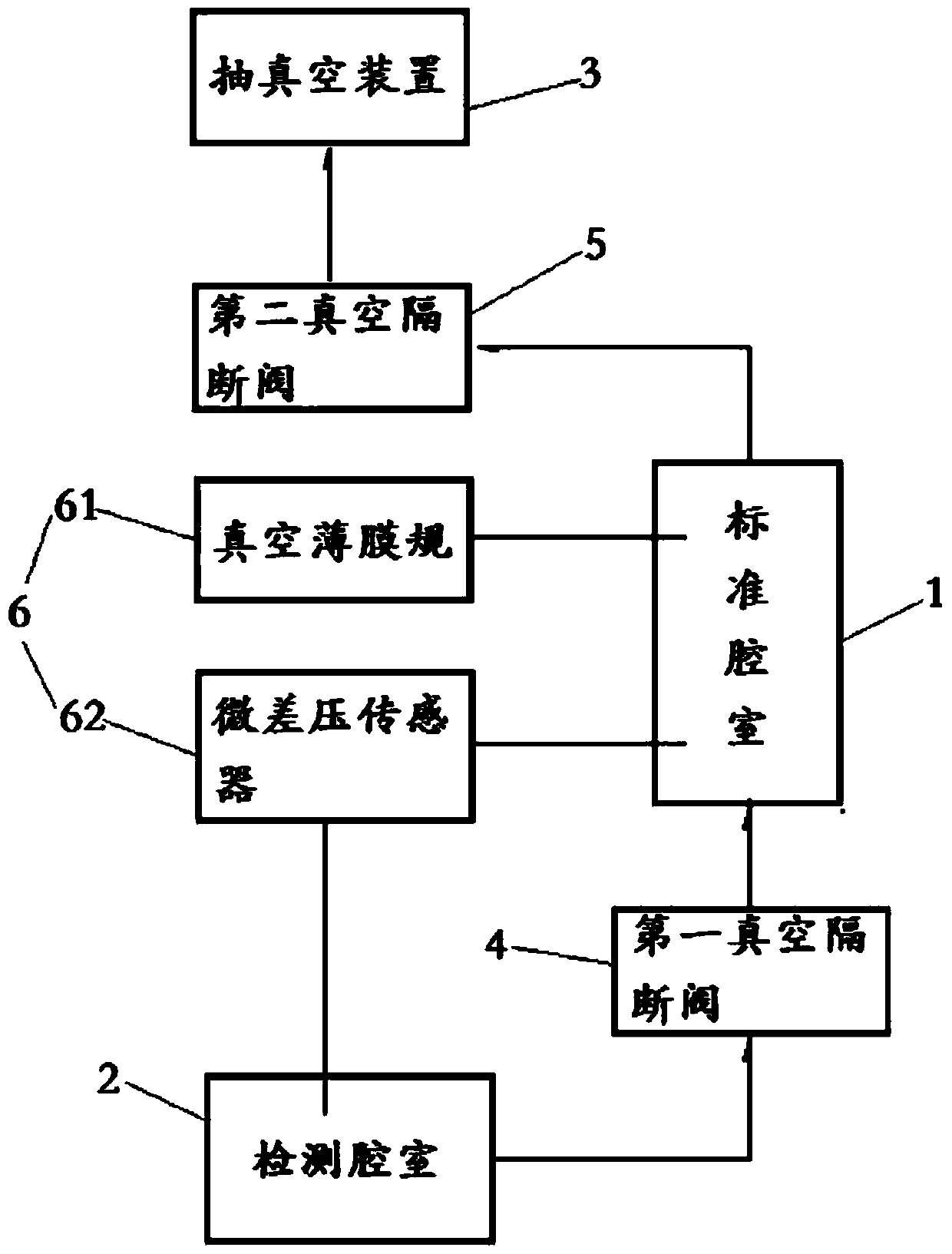

[0029] Such as figure 1 As shown, the embodiment of the present invention provides a kind of sealing test system, comprises airtight container, vacuum device 3, detection device 6, PLC controller (not shown in the figure), and described airtight container has a detection chamber 2 and standard Chamber 1, the detection chamber 2 communicates with the standard chamber 1 through the first vacuum isolation valve 4, and the vacuum device 3 communicates with the standard chamber through the second vacuum isolation valve 5. In this embodiment Among them, preferably, the vacuum pumping device 3 includes a first vacuum pump, a second vacuum pump, and a third vacuum pump, and the first vacuum pump, the second vacuum pump, and the third vacuum pump are sequentially connected in series, and the first vacuum pump and the first vacuum pump Two vacuum isolation valves 5 are connected; by adopting three vacuum pumps connected in series to vacuumize the sealing test system, the vacuuming effic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com